Preparation method for heterojunction photocatalyst and application

A photocatalyst and heterojunction technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of unsatisfactory photocatalytic degradation effect of organic pollutants and low degradation efficiency of organic pollutants , low photocatalytic degradation performance, etc., to achieve the effects of excellent photocatalytic degradation activity, effective photocatalytic degradation, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

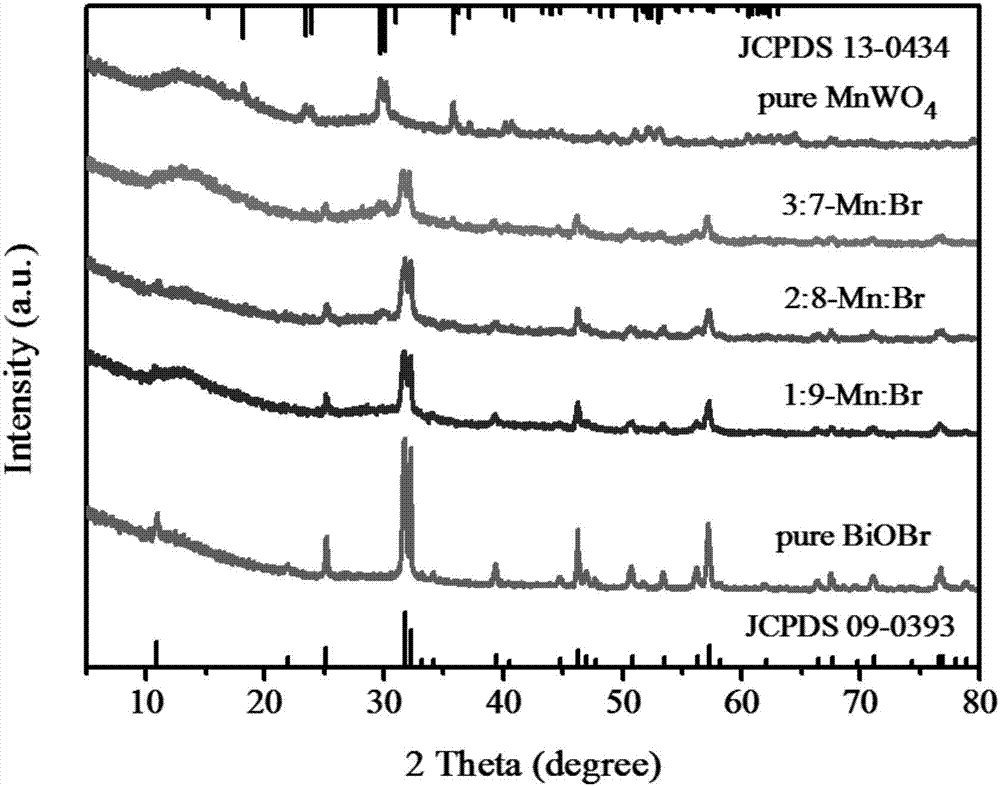

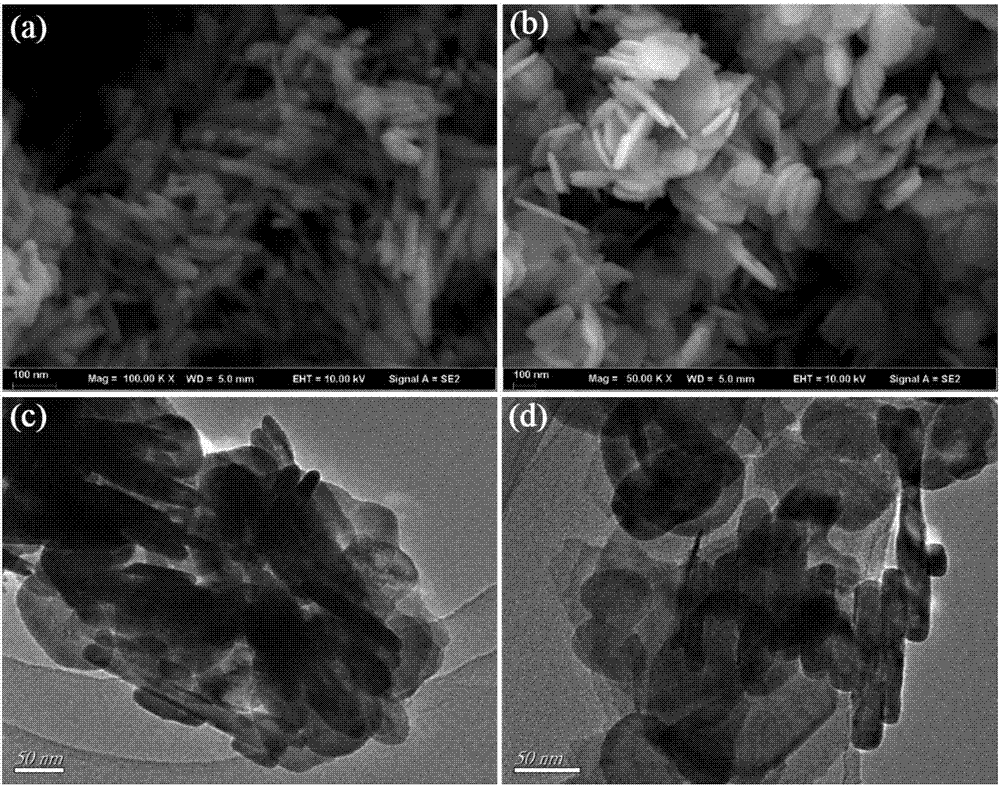

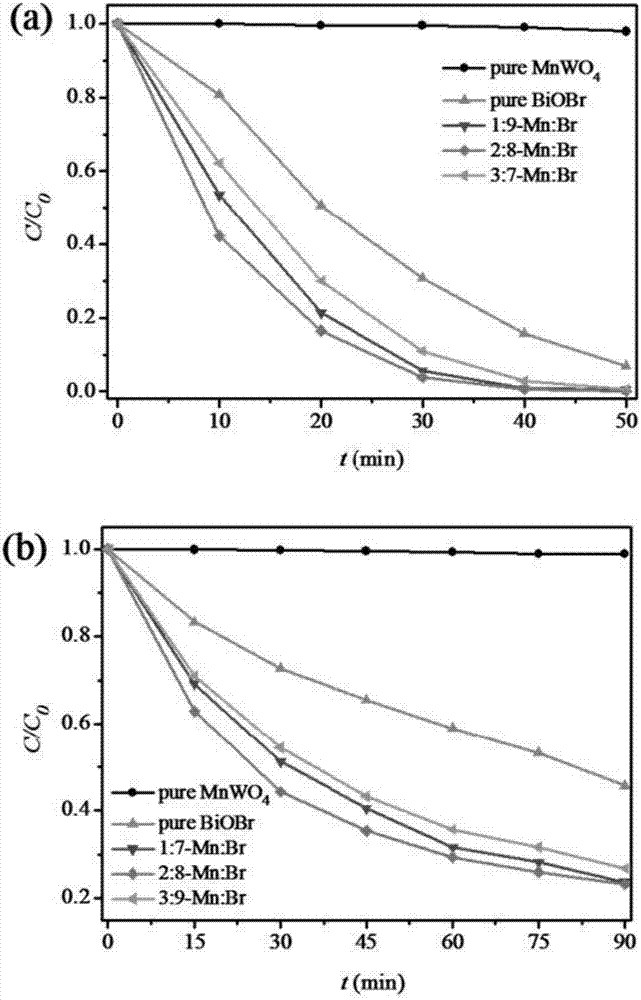

[0029] Step (1): Weigh 1mmol manganous chloride (0.198g) and 1mmol sodium tungstate (0.330g) and dissolve them in 30mL deionized water, ultrasonically dissolve to obtain a suspension, and then adjust the pH with 1mmol / L sodium hydroxide solution value to 9, then transferred to a 50mL hydrothermal reaction kettle, hydrothermally reacted at 180°C for 24h, finally washed with water, filtered, and dried to obtain manganese tungstate A.

[0030] Step (2): Weigh 1mmol of bismuth nitrate (0.485g) and dissolve it in 20mL of ethylene glycol, and ultrasonically dissolve to obtain a white suspension; weigh 1mmol of potassium bromide (0.119g) and dissolve it in 10mL of deionized water, and ultrasonically disperse to obtain a transparent solution, and then the potassium bromide solution was added dropwise to the above-mentioned bismuth nitrate suspension, stirred at room temperature for 30min after the dropwise addition, and then transferred to a 50mL hydrothermal reaction kettle, hydrother...

Embodiment 2

[0033]Step (1): Weigh 1mmol manganous chloride (0.198g) and 1mmol sodium tungstate (0.330g) and dissolve them in 30mL deionized water, ultrasonically dissolve to obtain a suspension, and then adjust the pH with 1mmol / L sodium hydroxide solution value to 9, then transferred to a 50mL hydrothermal reaction kettle, hydrothermally reacted at 180°C for 24h, finally washed with water, filtered, and dried to obtain manganese tungstate A.

[0034] Step (2): Weigh 1mmol of bismuth nitrate (0.485g) and dissolve it in 20mL of ethylene glycol, and ultrasonically dissolve to obtain a white suspension; weigh 1mmol of potassium bromide (0.119g) and dissolve it in 10mL of deionized water, and ultrasonically disperse to obtain a transparent solution, and then the potassium bromide solution was added dropwise to the above-mentioned bismuth nitrate suspension, stirred at room temperature for 30min after the dropwise addition, and then transferred to a 50mL hydrothermal reaction kettle, hydrotherm...

Embodiment 3

[0037] Step (1): Weigh 1mmol manganous chloride (0.198g) and 1mmol sodium tungstate (0.330g) and dissolve them in 30mL deionized water, ultrasonically dissolve to obtain a suspension, and then adjust the pH with 1mmol / L sodium hydroxide solution value to 9, then transferred to a 50mL hydrothermal reaction kettle, hydrothermally reacted at 180°C for 24h, finally washed with water, filtered, and dried to obtain manganese tungstate A.

[0038] Step (2): Weigh 1mmol of bismuth nitrate (0.485g) and dissolve it in 20mL of ethylene glycol, and ultrasonically dissolve to obtain a white suspension; weigh 1mmol of potassium bromide (0.119g) and dissolve it in 10mL of deionized water, and ultrasonically disperse to obtain a transparent solution, and then the potassium bromide solution was added dropwise to the above-mentioned bismuth nitrate suspension, stirred at room temperature for 30min after the dropwise addition, and then transferred to a 50mL hydrothermal reaction kettle, hydrother...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com