Preparation method of mildew-preventing and freshness-preserving PVA coating film

A coating film and anti-mildew technology, applied in the direction of coating, etc., can solve the problems of inappropriate selection of defoaming agent for coating barrier properties, decreased oxygen barrier properties, poor water resistance, etc., and achieves excellent oxygen barrier properties and reduced viscosity. Larger, stronger adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of hydrotalcite-like modified nanoparticles:

[0033] 1) 10g Mg(NO 3 )2·6H 2 O, Al(NO 3 )3·6H 2 O was dispersed in water and stirred at 200rpm, and the temperature was raised to 60°C; then 2mol / L NaOH aqueous solution was added dropwise to maintain the pH of the system between 10.0-11.0; Mg(NO 3 )2·6H 2 O and Al(NO 3 )3·6H 2 The molar ratio of O is 2:3;

[0034]2) Stir and age at 60°C for 6 hours, then filter, and put the obtained precipitate into a nitrogen-protected calciner for calcination, from room temperature to 400°C for calcination, the heating rate is 15°C / min, and the calcination time is 8 hours, After the calcination is completed, the temperature is naturally cooled to room temperature, and the product obtained is a hydrotalcite-like material;

[0035] 3) Take 10g of hydrotalcite-like material and disperse it in 100ml of 0.02mol / L KF aqueous solution, then add 0.32g of sodium benzotriazolyl butylphenol sulfonate, heat up to reflux and stir...

Embodiment 2

[0038] Compared with Example 1, step 3) increases the pretreatment of ultrasonic dispersion, and the calcination temperature is increased, and the rest is exactly the same as Example 1; that is, the only difference is that 10g of hydrotalcite-like material is dispersed in 100ml of 0.02mol / L Ultrasonic dispersion in KF aqueous solution at 40°C for 0.5h, then add 0.32g sodium benzotriazolyl butylphenol sulfonate, heat up to reflux and stir for 24h, cool down, filter, wash with purified water, and calcined at 660-700°C under nitrogen atmosphere Hydrotalcite-modified nanoparticle precursors.

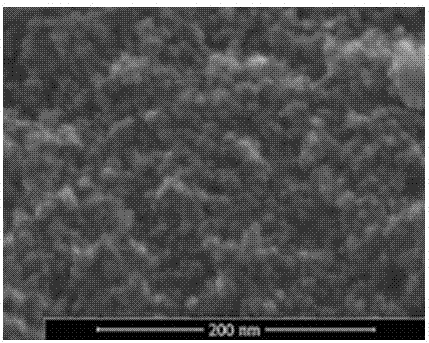

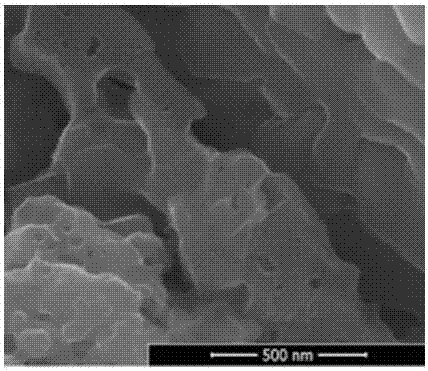

[0039] The hydrotalcite-like modified nanoparticle scanning electron microscope SEM that embodiment 2 prepares sees figure 2

[0040] Depend on figure 1 with figure 2 It can be seen from the scanning electron microscope results that in the preparation process of the hydrotalcite-like modified nanoparticles, the preparation process of the intercalation agent KF and benzotriazolyl butylph...

Embodiment 3

[0042] The preparation of PVA / hydrotalcite-like modified nanoparticles composite liquid comprises the following steps:

[0043] 1) Take 100ml of purified water and add it to the reactor, add 12g of PVA17-99 into the water at a speed of 400rpm and stir;

[0044] 2) Then add 0.2g glycerol, 0.3g polyoxyethylene polyoxypropylene pentaerythritol ether, 0.2g hydrotalcite-like modified nanoparticles (prepared in Example 2) and heat up to 80°C, and disperse into PVA17- 99 was completely dissolved, then kept for 2 hours, and cooled to room temperature to obtain a composite solution of PVA / hydrotalcite-like modified nanoparticles.

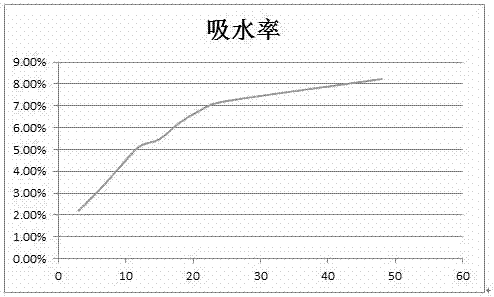

[0045] The viscosity of the PVA / hydrotalcite-like modified nanoparticle composite liquid was tested with Zahn Cup 3# (unit: S). The measured viscosity was 37.3 after preparation at room temperature, 39.0 after 60 hours at 30°C, and 39.0 after 120 hours at 30°C. The viscosity is 41.0; the viscosity is 45.0 after being placed at 10°C for 60 hours, and the vis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com