Toughening and plasticizer migration-resisting polyvinyl chloride material as well as preparation method and application thereof

A polyvinyl chloride and plasticizer-resistant technology, applied in the field of toughened plasticizer-resistant migration polyvinyl chloride materials and its preparation, can solve the problems of reduced flexibility due to plasticization, and achieve improved dimensional stability and processing Fluidity, large surface area, effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

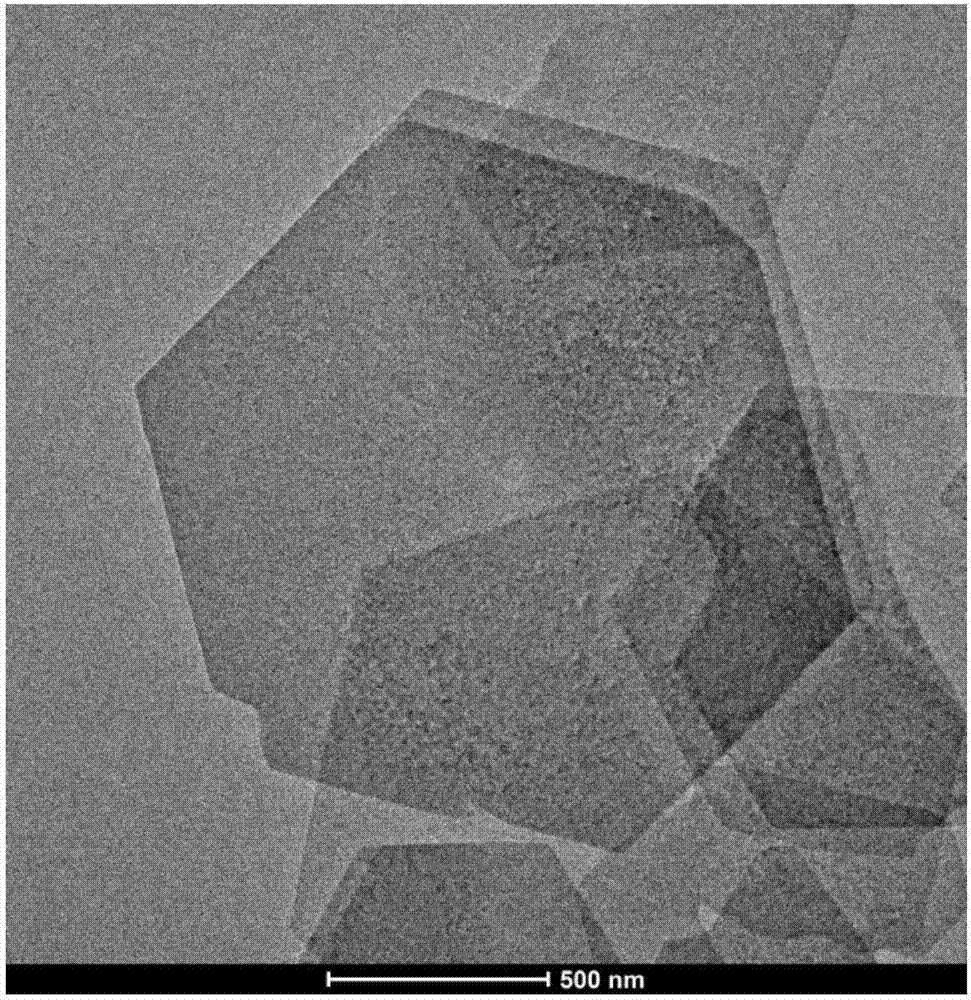

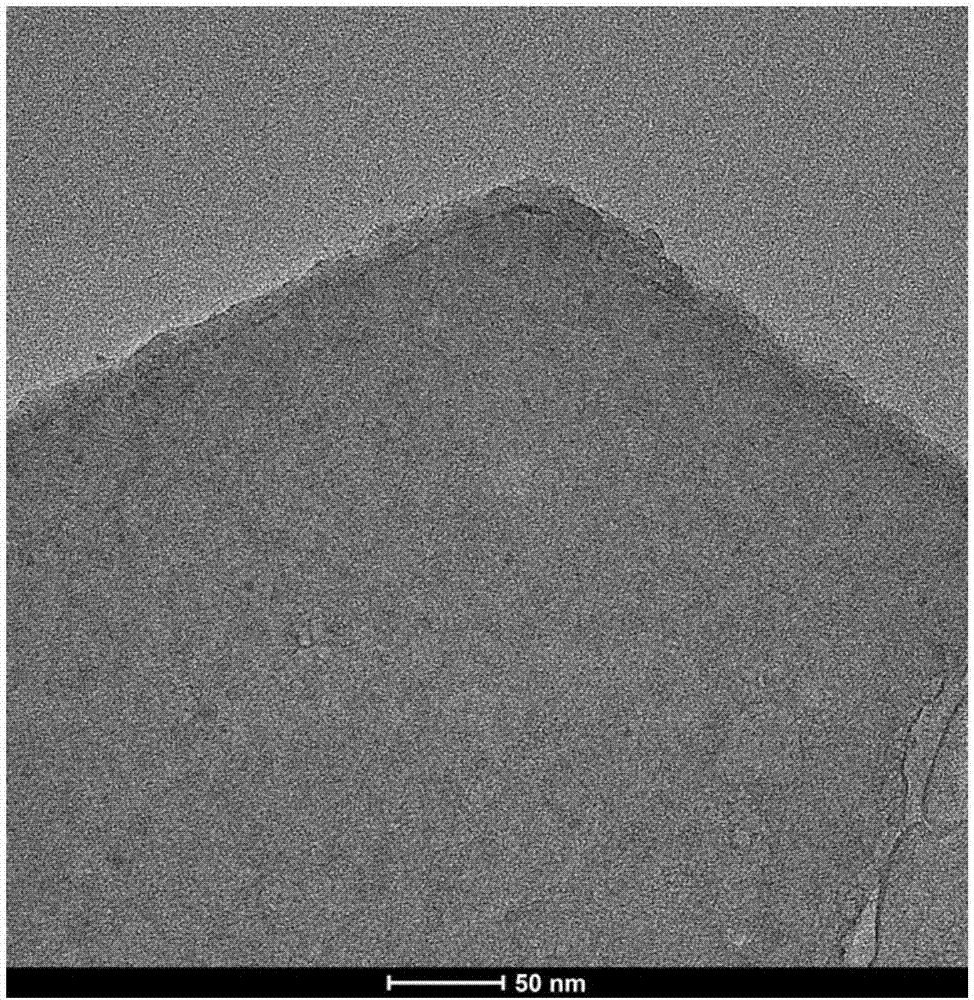

[0046] (1) Weigh 0.18 mol of magnesium chloride, 0.08 mol of zinc chloride, 0.1 mol of aluminum chloride and 0.385 mol of urea and dissolve them in deionized water, then sonicate for 30 minutes, transfer them to an autoclave, and then place them at 180°C React in a muffle furnace for 18 hours. After the reaction, filter and wash to obtain LDHs powder.

[0047] (2) Weigh 0.1g of LDHs into 100ml of deionized water, sonicate for 30min, then add 0.05g of dopamine hydrochloride, after fully dissolving and dispersing, then add 1.5g of tris, and continue to stir and react for 6h at room temperature , after the reaction, filter and wash to obtain LDHs@PDA powder.

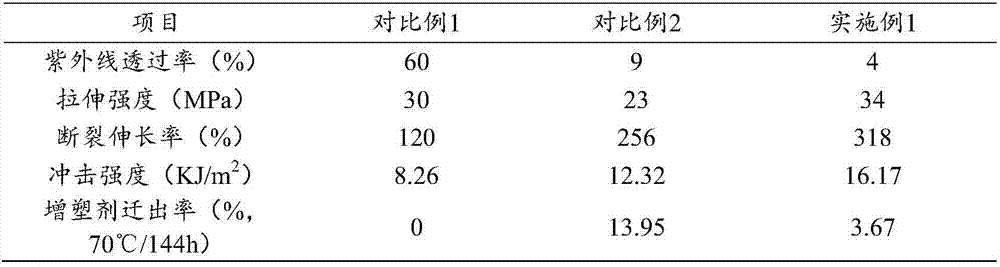

[0048] (3) Put 50g of polyvinyl chloride, 20g of dioctyl phthalate, 1g of barium cadmium stearate, 1.5g of lanthanum stearate, and 1g of LDHs@PDA into a high-speed blender for blending, Transfer to a torque rheometer and melt blend for 15 minutes to obtain modified polyvinyl chloride. The temperature of the torque rheomete...

Embodiment 2

[0051] (1) Weigh 0.2 mol of calcium chloride, 0.1 mol of aluminum chloride and 0.33 mol of urea to dissolve in deionized water, then sonicate for 40 minutes, transfer to a high-pressure reactor, and then put it into a muffle furnace at 120°C After the reaction was completed for 36 hours, the LDHs powder was obtained by filtering and washing.

[0052] (2) Weigh 0.01g of LDHs into 100ml of deionized water, sonicate for 20min, then add 0.02g of dopamine, after fully dissolving and dispersing, add 0.8g of tris, continue to stir and react for 4h at room temperature, After the reaction, filter and wash to obtain LDHs@PDA powder.

[0053] (3) 50g of polyvinyl chloride, 20g of dioctyl phthalate, 5g of dimethyl phthalate, 2.5g of calcium stearate and 1.5g of lanthanum stearate, 1.5g of LDHs After @PDA was blended in a high-speed blender, it was transferred to a torque rheometer for melt blending for 45 minutes to obtain modified polyvinyl chloride. The temperature of the torque rheome...

Embodiment 3

[0056] (1) Weigh 0.4mol of zinc chloride of nickel chloride, 0.05mol of aluminum chloride, 0.05mol of cerium chloride and 0.525mol of urea and dissolve them in deionized water, then ultrasonically for 50min, transfer to the autoclave, Then put it into a muffle furnace at 180° C. to react for 6 hours. After the reaction, filter and wash to obtain LDHs powder.

[0057] (2) Weigh 0.08g of LDHs and add it to 100ml of deionized water, sonicate for 50min, then add 0.08g of dopamine hydrochloride, after fully dissolving and dispersing, add 1.2g of tris, continue to stir and react for 12h at room temperature , after the reaction, filter and wash to obtain LDHs@PDA powder.

[0058] (3) Put 75g of polyvinyl chloride, 5g of epoxidized soybean oil, 3g of zinc stearate, and 0.1g of LDHs@PDA into a high-speed blender for blending, then transfer them to a torque rheometer to melt and blend Mix for 10 minutes to obtain modified polyvinyl chloride, set the temperature of the torque rheometer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com