A high-power and low-noise planar Gunn diode and its preparation method

A Gunn diode and low-noise technology, applied in the field of diodes in microwave devices, can solve the problems of losing the advantages of two-dimensional integration, large phase noise of devices, and few resonant cavities, achieving small size, reducing phase noise, and improving emission The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

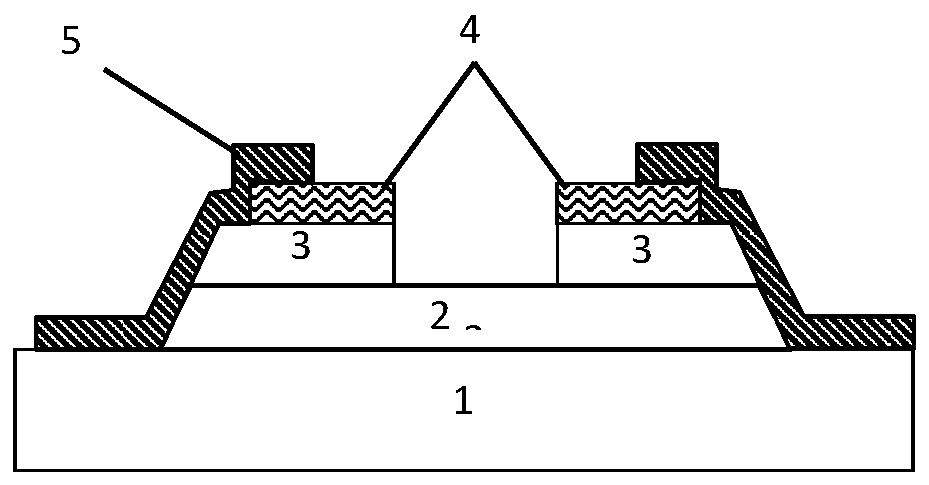

[0043] A high-power and low-noise planar Gunn diode, comprising an insulating substrate 1, a channel layer 2, and a coplanar waveguide 5 arranged on the channel layer 2, the resonant cavity length of the coplanar waveguide 5 is half of the resonance Integer multiples of the wavelength, the characteristic impedance of the coplanar waveguide 5 at the resonant frequency is equal to the load impedance 50Ω.

[0044] The load impedance is 50Ω, and the resonant frequency is 100GHz. At this time, the ratio of the width of the central wire of the coplanar waveguide 5 to the width of the electrode gaps on both sides is about 3.3:2.

[0045] The material of the coplanar waveguide 5 is silver, gold and copper, and the thickness of the coplanar waveguide 5 is greater than three times of the skin depth. The advantage of the design here is to reduce the loss and improve the Q value of the resonant cavity.

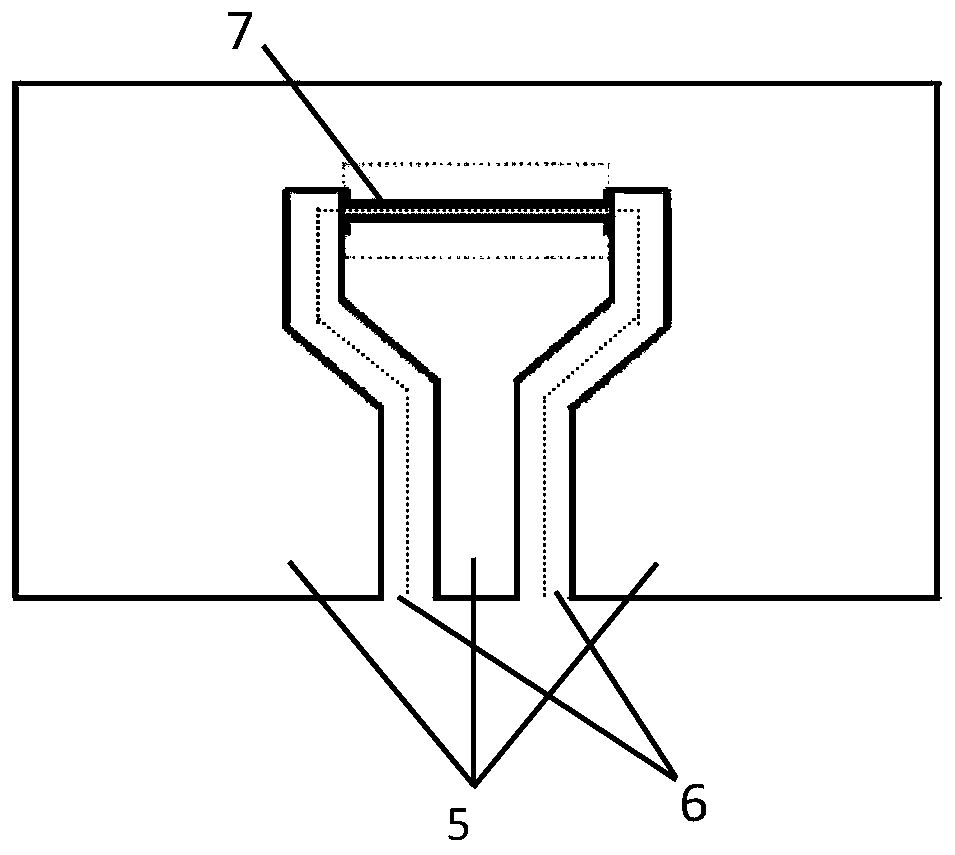

[0046] Such as figure 2 As shown, the coplanar waveguide 5 propagates electromagneti...

Embodiment 2

[0056] The preparation method of the planar Gunn diode described in embodiment 1, concrete steps comprise:

[0057] (1) Use semi-insulating InP as the insulating substrate 1, and use MBE epitaxy to grow 300nm n-type In on the insulating substrate 1 0.53 al 0.47 As is used as the buffer layer, 300nm n-type InGaAs is used as the channel layer 2, and the doping concentration of the channel layer 2 is 1×10 16 cm -3 . 200nm heavily doped InGaAs is epitaxially grown on the channel layer 2 as the cap layer 3, and the doping concentration of the cap layer 3 is 1×10 18 cm -3 .

[0058] (2) Spin-coat PMMA electron beam glue on the sample as an etching mask, and use electron beam exposure equipment to expose PMMA electron beam glue to form a mesa pattern. Use a 3:1 mixed solution of phosphoric acid and hydrogen peroxide to etch the mesa to form electrical isolation between devices. Remove residual PMMA e-beam glue.

[0059] (3) Spin-coat PMMA electron beam glue on the sample as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com