Quantitative glucose beverage for glucose tolerance detection test and production technology thereof

A technology of glucose and laboratory, applied in the field of quantitative glucose beverage and its production process, can solve the problems of unknown influence of glucose metabolism, no description of glucose, failure to meet clinical needs, etc., achieve accurate measurement, good taste, and ensure drug safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

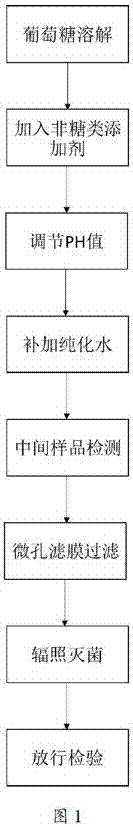

Method used

Image

Examples

Embodiment 1

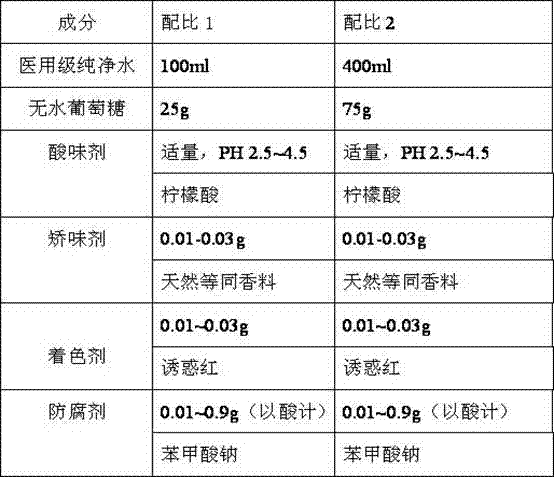

[0043] Embodiment 1: Quantitative glucose beverage production process required for the glucose tolerance test of 50g anhydrous glucose amount, formula is as follows:

[0044] 300ml / bottle 1 bottle

[0045] Anhydrous glucose 50g

[0046] Sodium benzoate 0.01~0.9g (as acid)

[0047] Citric acid amount

[0048] Sunset yellow 0.01~0.03g

[0049] Allure Red 0.01~0.03g

[0050] Appropriate amount of flavoring agent

[0051] Purified water to 300ml

[0052] production process:

[0053] Step 1: Weigh 50g of anhydrous glucose with a predetermined weight and dissolve it in 1 / 2~2 / 3 volume of purified water of 300ml of the total amount of purified water, that is, dissolve 50g of anhydrous glucose in 150~200ml of purified water, stir and heat to Anhydrous glucose is completely dissolved to obtain solution I, the stirring time is generally 10-20 minutes, and the heating temperature is 60-80°C.

[0054] Step 2: Add sodium benzoate, sunset yellow, allura red, and flavoring agents to s...

Embodiment 2

[0069] Embodiment 2: Quantitative glucose beverage production technology required for the glucose tolerance test of 50g anhydrous glucose amount, formula is as follows:

[0070] 300ml / bottle 1000 bottles

[0071] Anhydrous glucose 50000g

[0072] Sodium benzoate 10~900g (as acid)

[0073] Citric acid amount

[0074] Sunset yellow 10~30g

[0075] Allure Red 10~30g

[0076] Appropriate amount of flavoring agent

[0077] Purified water up to 300000ml

[0078] production process:

[0079] Step 1: Weigh 50,000g of anhydrous glucose with a predetermined weight, and dissolve it in 1 / 2~2 / 3 volume of purified water of 300,000ml of purified water, that is, dissolve 50,000g of anhydrous glucose in 150,000~200,000ml of purified water, stir and heat to Anhydrous glucose is completely dissolved to obtain solution I, the stirring time is generally 10-20 minutes, and the heating temperature is 60-80°C.

[0080] Step 2: Add sodium benzoate, sunset yellow, allura red, and natural season...

Embodiment 3

[0095] Embodiment 3: Quantitative glucose beverage production process required for the glucose tolerance test of 75g anhydrous glucose amount, formula is as follows:

[0096] 300ml / bottle 1 bottle

[0097] Anhydrous glucose 75g

[0098] Sodium benzoate 0.01~0.9g (as acid)

[0099] Citric acid amount

[0100] Gum Arabic 0.01~3g

[0101] Allure Red 0.01~0.03g

[0102] Appropriate amount of flavoring agent

[0103] Glycerin abietic acid ester (rosin glyceride) 0.01~0.03g

[0104] Purified water to 300ml

[0105] production process:

[0106] Step 1: Weigh 75g of anhydrous glucose with a predetermined weight and dissolve it in 1 / 2~2 / 3 volume of purified water of 300ml of the total amount of purified water, that is, dissolve 75g of anhydrous glucose in 150~200ml of purified water, stir and heat to Anhydrous glucose is completely dissolved to obtain solution I, the stirring time is generally 10-20 minutes, and the heating temperature is 60-80°C.

[0107] Step 2: Add sodium b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com