Preparation method of secondary alcohol ethoxylate

A technology of secondary alcohol polyoxyethylene ether and polyoxyethylene ether, which is applied in the field of preparation of secondary alcohol polyoxyethylene ether and can solve the problems of low PEG content of secondary alcohol polyoxyethylene ether and high PEG content of crude products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

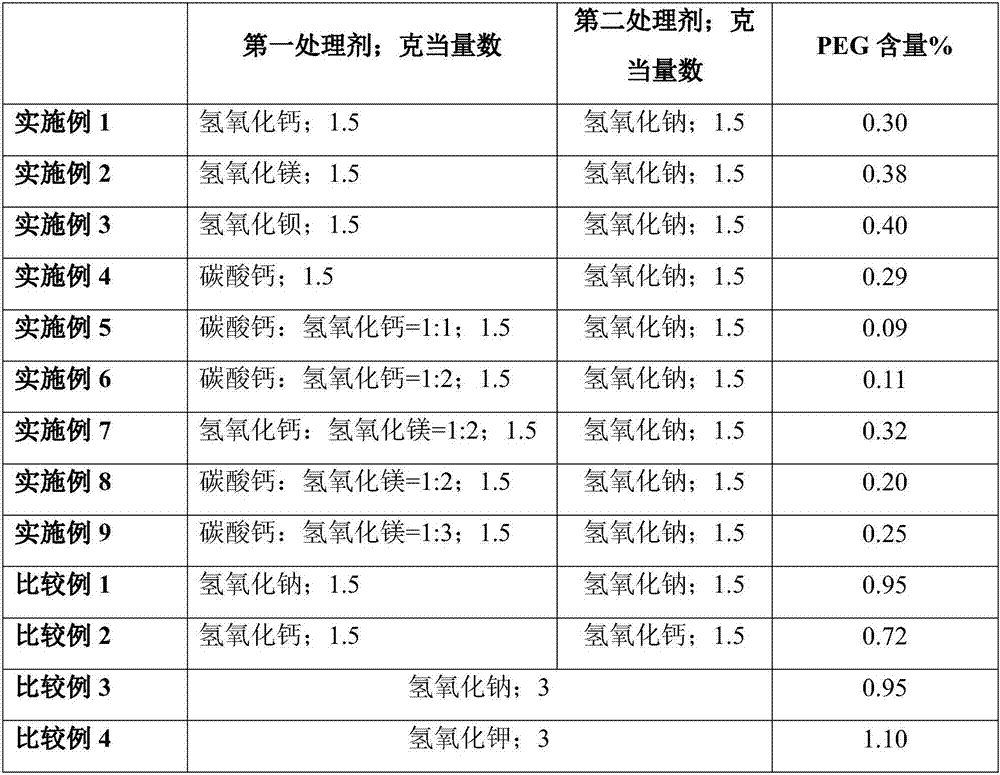

Examples

Embodiment 1

[0043]Add 1 mole of C13 secondary alcohol and 0.34 g of boron trifluoride into a 1 L stirred autoclave, seal the autoclave, and start stirring. Use nitrogen to replace the air in the reactor for three times, then feed ethylene oxide into the reactor, control the reaction temperature at 70°C and the reaction pressure at 0.2MPa, until the total amount of ethylene oxide fed is 3 moles, that is, synthesis C13 secondary alcohol polyoxyethylene (3) ether, until the pressure of the reactor no longer drops, it indicates that the aging reaction is completed, and the crude product of secondary alcohol polyoxyethylene (3) ether is obtained, the temperature is lowered and maintained at 50 ° C, and 1.5 times the amount of secondary alcohol polyoxyethylene (3) ether is added. Calcium hydroxide powder of the boron trifluoride gram equivalent number in the crude product of oxyethylene (3) ether, stirred for 2 hours, with 1.5 times of the boron trifluoride gram equivalent number in the secondar...

Embodiment 2

[0046] Add 1 mole of C13 secondary alcohol and 0.34 g of boron trifluoride into a 1 L stirred autoclave, seal the autoclave, and start stirring. Use nitrogen to replace the air in the reactor for three times, then feed ethylene oxide into the reactor, control the reaction temperature at 70°C and the reaction pressure at 0.2MPa, until the total amount of ethylene oxide fed is 3 moles, that is, synthesis C13 secondary alcohol polyoxyethylene (3) ether, until the pressure of the reactor no longer drops, it indicates that the aging reaction is completed, and the crude product of secondary alcohol polyoxyethylene (3) ether is obtained, the temperature is lowered and maintained at 50 ° C, and 1.5 times the amount of secondary alcohol polyoxyethylene (3) ether is added. The magnesium hydroxide powder of the boron trifluoride gram equivalent number in the crude product of oxyethylene (3) ether, stirred for 2 hours, with 1.5 times of the boron trifluoride gram equivalent number in the s...

Embodiment 3

[0049] Add 1 mole of C13 secondary alcohol and 0.34 g of boron trifluoride into a 1 L stirred autoclave, seal the autoclave, and start stirring. Use nitrogen to replace the air in the reactor for three times, then feed ethylene oxide into the reactor, control the reaction temperature at 70°C and the reaction pressure at 0.2MPa, until the total amount of ethylene oxide fed is 3 moles, that is, synthesis C13 secondary alcohol polyoxyethylene (3) ether, until the pressure of the reactor no longer drops, it indicates that the aging reaction is completed, and the crude product of secondary alcohol polyoxyethylene (3) ether is obtained, the temperature is lowered and maintained at 50 ° C, and 1.5 times the amount of secondary alcohol polyoxyethylene (3) ether is added. The barium hydroxide powder of the boron trifluoride gram equivalent number in the crude product of oxyethylene (3) ether, stirred 2 hours, with 1.5 times of the boron trifluoride gram equivalent number in the secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com