Wear-resistant ultraviolet curing silk printing snowflake printing ink

A snowflake ink and ultraviolet light technology, applied in inks, household appliances, applications, etc., can solve the problems of disordered snowflake particle aggregation, insignificant snowflake effect, and unsatisfactory silk-screen snowflake ink adhesion and friction resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

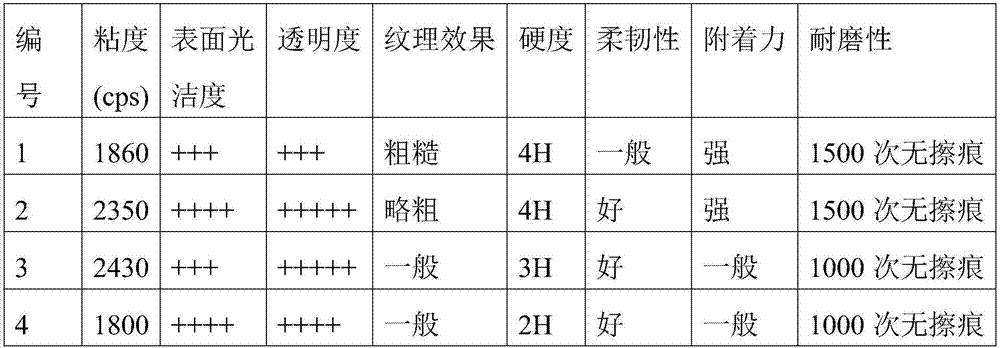

Embodiment 1

[0028] A wear-resistant UV-curable silkscreen snowflake ink, comprising the following components:

[0029] 60 parts of photocurable resin, wherein, photocurable resin is the mixture of aminoacrylic resin and hydroxyl acrylic resin (mass ratio is 1:4);

[0030] 4 parts of photoinitiator, photoinitiator is benzoin;

[0031] 2 parts of photosensitization accelerator, photosensitization accelerator is dimethylaminoethyl methacrylate;

[0032] 10 parts of photosensitive nano silicon dioxide, the surface of the silicon dioxide particles is modified by methacryloxypropyl trimethyloxysilane, the particle diameter of the silicon dioxide particles is 40nm; the surface of the photosensitive nano silicon dioxide Modified bonding ratio is 45;

[0033] 0.3 parts of defoamer, the model of defoamer is X-2080;

[0034] 2 parts of leveling agent, the type of leveling agent is TEGOGlide432;

[0035] 0.1 part of polymerization inhibitor, polymerization inhibitor is hydroquinone;

[0036] 13 ...

Embodiment 2

[0039] A wear-resistant UV-curable silkscreen snowflake ink, comprising the following components:

[0040] 60 parts of photocurable resin, wherein the photocurable resin is a mixture of aminoacrylic resin, epoxy acrylic resin and polyketone resin (mass ratio is 1:2:0.5);

[0041] 3 parts of photoinitiator, photoinitiator is camphorquinone;

[0042] 1 part of photosensitization accelerator, the photosensitization accelerator is dimethylaminoethyl methacrylate;

[0043] 10 parts of photosensitive nano silicon dioxide, the surface of the silicon dioxide particles is modified by methacryloxypropyl trimethyloxysilane, the particle diameter of the silicon dioxide particles is 30nm; the surface of the photosensitive nano silicon dioxide Modified bonding rate is 50;

[0044] 0.3 parts of defoamer, the model of defoamer is X-2080;

[0045] 2 parts of leveling agent, the type of leveling agent is TEGOGlide432;

[0046] 0.1 part of polymerization inhibitor, polymerization inhibitor i...

Embodiment 3

[0050] A wear-resistant UV-curable silkscreen snowflake ink, comprising the following components:

[0051] 63 parts of photocurable resin, wherein the photocurable resin is a mixture of aminoacrylic resin, epoxy acrylic resin and polyaldehyde resin (mass ratio is 1:2:0.4);

[0052] 3 parts of photoinitiator, photoinitiator is camphorquinone;

[0053] 1 part of photosensitization accelerator, the photosensitization accelerator is dimethyl p-toluidine;

[0054] 10 parts of photosensitive nano silicon dioxide, the surface of the silicon dioxide particles is modified by methacryloxypropyl trimethyloxysilane, the particle diameter of the silicon dioxide particles is 35nm; the surface of the photosensitive nano silicon dioxide Modified bonding ratio is 45;

[0055] 0.3 parts of defoamer, the model of defoamer is X-2080;

[0056] 2 parts of leveling agent, the type of leveling agent is TEGOGlide432;

[0057] 0.1 part of polymerization inhibitor, polymerization inhibitor is hydroq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com