A kind of non-precious metal catalyst and preparation method thereof

A non-precious metal, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of poor tolerance and long-term operation stability, low catalytic activity and stability, and preparation conditions. Harsh and other problems, to achieve the effects of good CH3OH tolerance, low price, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the non-noble metal catalyst provided by the present invention comprises the following steps:

[0032] (1) The metal compound and the organic molecular linking agent are dissolved in the solvent respectively at a molar ratio of 1: (3 to 4), and the obtained two solutions are uniformly mixed; the mixed solution is left to stand, so that the metal ion and Organic molecules undergo a chelation reaction to generate a precipitate; the precipitate is treated by centrifugation or suction filtration to obtain an intermediate product; and the intermediate product is dried to obtain a precursor;

[0033] (2) The precursor is placed under an inert atmosphere, and the temperature is raised to 600-1000° C. at a rate of 5-10° C. / min, and a pyrolytic carbonization treatment is performed at this temperature to obtain a non-precious metal catalyst.

Embodiment 1

[0036] A non-noble metal-doped porous carbon-nitrogen material catalyst, the preparation method of which is as follows:

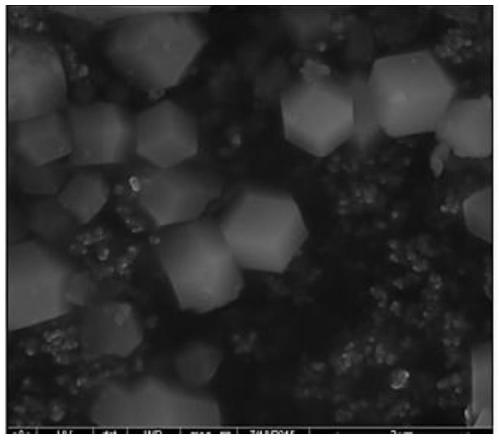

[0037] (1) After dissolving the metal compound (cobalt nitrate) and the organic molecule linking agent (dimethylimidazole) in a molar ratio of 1:4 in anhydrous methanol, the two solutions obtained by dissolving are mixed and stirred evenly, Stand still at room temperature for 24h, make the metal ion in the metal compound and the organic molecule in the organic molecule linking agent carry out chelation reaction, generate precipitate; The precipitate is carried out centrifugation or suction filtration process, the solid (intermediate product) that obtains is in 80 Dry at ℃ to obtain a purple powdery precursor;

[0038] (2) Put the obtained purple powdery precursor in an inert atmosphere (N 2 ), at a rate of 5°C / min, the temperature is raised to 600-900°C, and the pyrolytic carbonization treatment is carried out at this temperature for 2-10 hours; a non-prec...

Embodiment 2

[0052] A non-noble metal-doped porous carbon-nitrogen material catalyst, the preparation method of which is as follows:

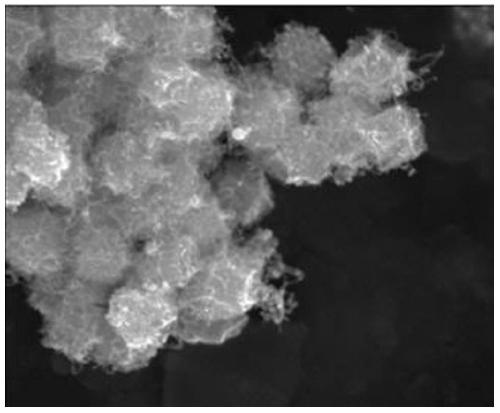

[0053] (1) Put the metal compound (the mixture of cobalt nitrate and copper nitrate, the molar ratio is 1 to 9:1) and the organic molecular linking agent (dimethylimidazole) in the molar ratio of 1:4, in anhydrous methanol After dissolving respectively in the solution, mix and stir the two solutions obtained by dissolving evenly, and let stand at room temperature for 12 hours, so that the metal ions and organic molecules undergo a sufficient chelation reaction to form a precipitate; the precipitate is subjected to centrifugation or suction filtration, The obtained solid was dried at 80°C to obtain a purple powdery precursor;

[0054] (2) Put the obtained purple powdery precursor in an inert atmosphere (N 2 ), at a heating rate of 10°C / min, the temperature is raised to 600-900°C, and the pyrolytic carbonization treatment is carried out at this temperature f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com