A kind of preparation method of heterogeneous oxidation reaction catalytic fiber

A heterogeneous oxidation and fiber technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. The reduction of the catalytic activity of the solid catalyst and the limitation of the catalytic activity of the catalyst have achieved the effect of outstanding reusability, stable reusability, and outstanding water and dissolution resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention provides a kind of preparation method (abbreviation method) of catalytic fiber of heterogeneous oxidation reaction, it is characterized in that, this method comprises the following steps:

[0028] Step 1, free radical polymerization makes carboxyl-containing polymer: the first monomer, the second monomer, initiator and deionized water are stirred until mixed uniformly to obtain a mixed system; then the mixed system is transferred to a closed environment (preferably In the polymerization kettle), pass inert gas to exhaust the residual air in the closed environment, stir and react at a temperature of 20-100°C (preferably 70-95°C) to form a gel-like product, and continue the reaction until no more gel-like product is generated (reaction time is 1-4h), stop stirring; after aging for 10-300min (preferably 90-150min), take out the gel-like product, fully dry in a hot box at a temperature of 50-120°C (preferably 60-90°C) After crushing, wash with deionize...

Embodiment 1

[0061] Steps 1, 2, and 3 of Example 1 are the same as Comparative Example 1, except that in Step 4, the as-spun fibers obtained in Step 3 are cut into 3 cm long, and stretched to 12 cm in an air medium at 25° C. Under tension, put it in a hot box at 60°C for heat setting treatment for 12 hours to prepare catalytic fibers.

[0062] The breaking strength of the fiber was measured to be 0.82 cN / dtex.

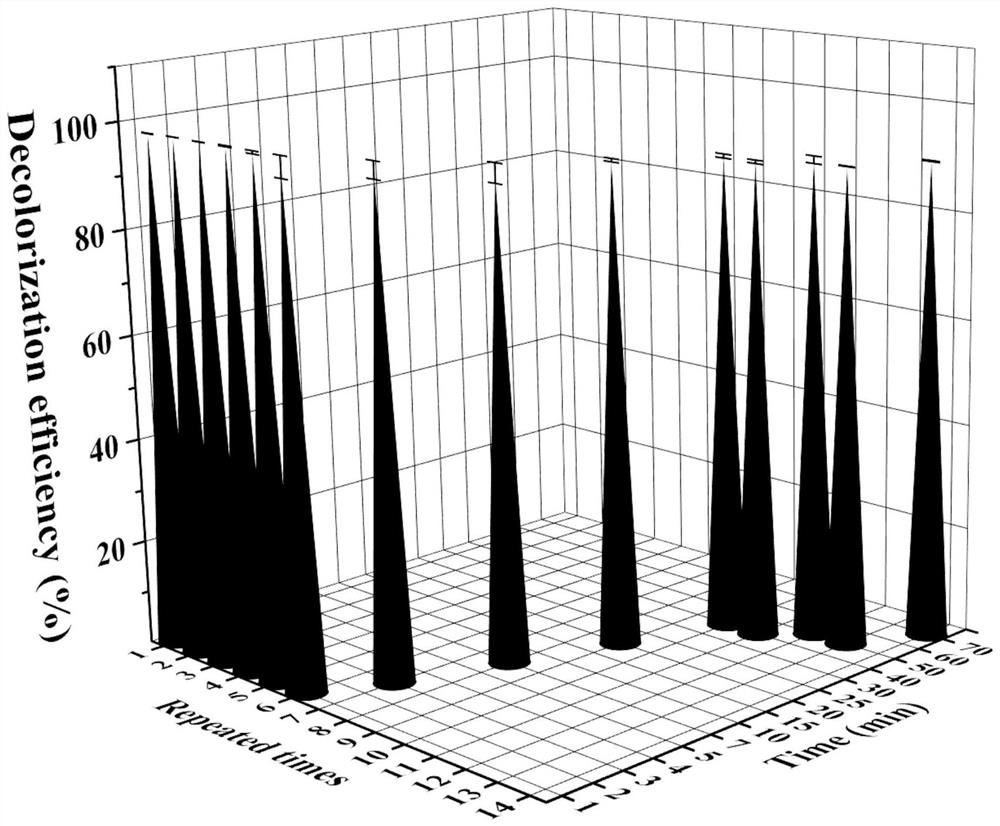

[0063] Take 10mL concentration of methylene blue aqueous solution of 20mg / L, add 2 μ L of hydrogen peroxide, place 10 catalytic fibers (mass is 0.06g) of 12cm long in the above solution, the removal rate of methylene blue within 1min is 95.63%; at this time, Quickly remove the catalytic fiber from the methylene blue aqueous solution, use filter paper to absorb excess liquid carried on the surface of the fiber, take 10 mL of methylene blue aqueous solution with a concentration of 20 mg / L, add 2 μL of hydrogen peroxide, and place the catalytic fiber that has completed the first catal...

Embodiment 2

[0065] Steps 1, 2, and 3 of Example 2 are the same as in Example 1, except that in Step 4, the as-spun fiber obtained in Step 3 is cut into a length of 3 cm, stretched to 12 cm in an air medium at 25° C. Under tension, place it in a hot box at 100°C for heat setting treatment for 5 hours to prepare catalytic fibers.

[0066] The breaking strength of the fiber was measured to be 0.91 cN / dtex.

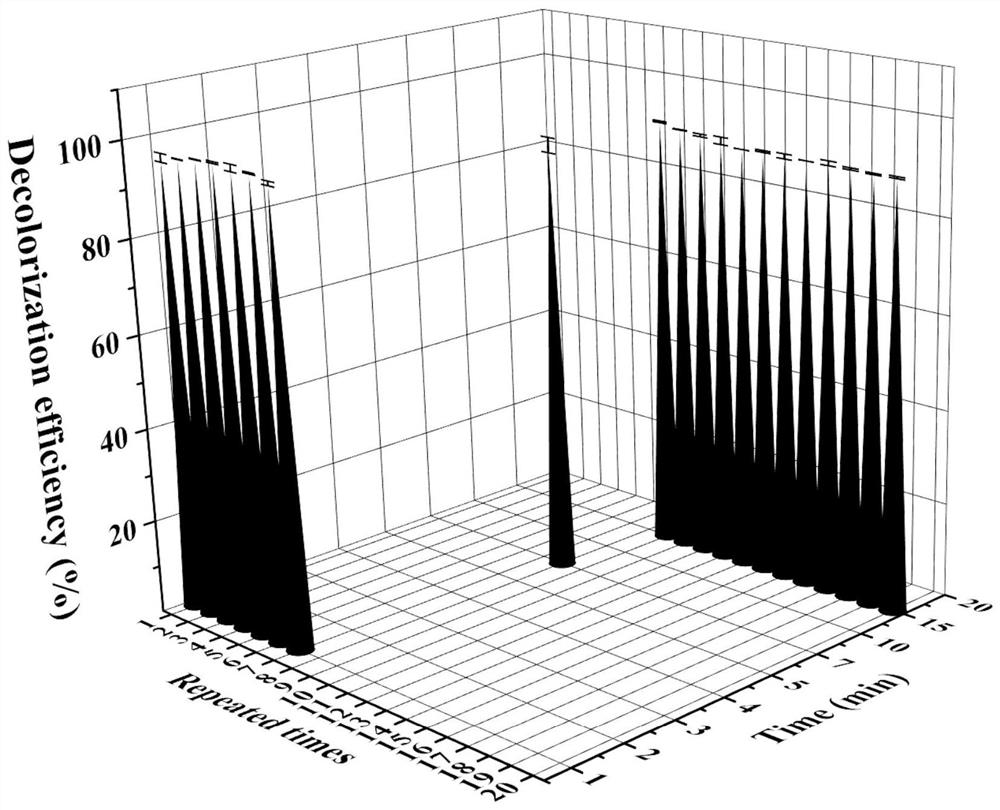

[0067] Take 10mL concentration of methylene blue aqueous solution of 20mg / L, add 2 μ L of hydrogen peroxide, put 10 catalytic fibers (mass is 0.06g) of 12cm long in the above solution, the removal rate of methylene blue within 1min is 97.48%; at this time, Quickly remove the catalytic fiber from the methylene blue aqueous solution, use filter paper to absorb excess liquid carried on the surface of the fiber, take 10 mL of methylene blue aqueous solution with a concentration of 20 mg / L, add 2 μL of hydrogen peroxide, and place the catalytic fiber that has completed the first catalysis in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com