Method for removing crystal violet dye in water by adopting sludge-based biomass hydrothermal carbon adsorbent

A biomass and hydrothermal carbon technology, applied in the fields of adsorption water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc. Problems such as poor biological availability of sludge, to achieve the effects of water environmental protection, low cost, and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Example 1: The sludge is centrifuged for preliminary dehydration, dried, ground, and sieved to 350-850 μm for later use. Weigh 50g of sludge particles, add 450ml of water, adjust the pH value of the mud-water mixture solution to 9 with 0.1mol / L HCl and NaOH solution, react at 180°C for 3h, take out the product and centrifuge to separate the solid and liquid, and then After washing several times with water, the solid was taken out and dried at 105° C. for 24 hours to obtain No. 1 sludge-based biomass hydrothermal carbon adsorbent with a yield of 44.80%.

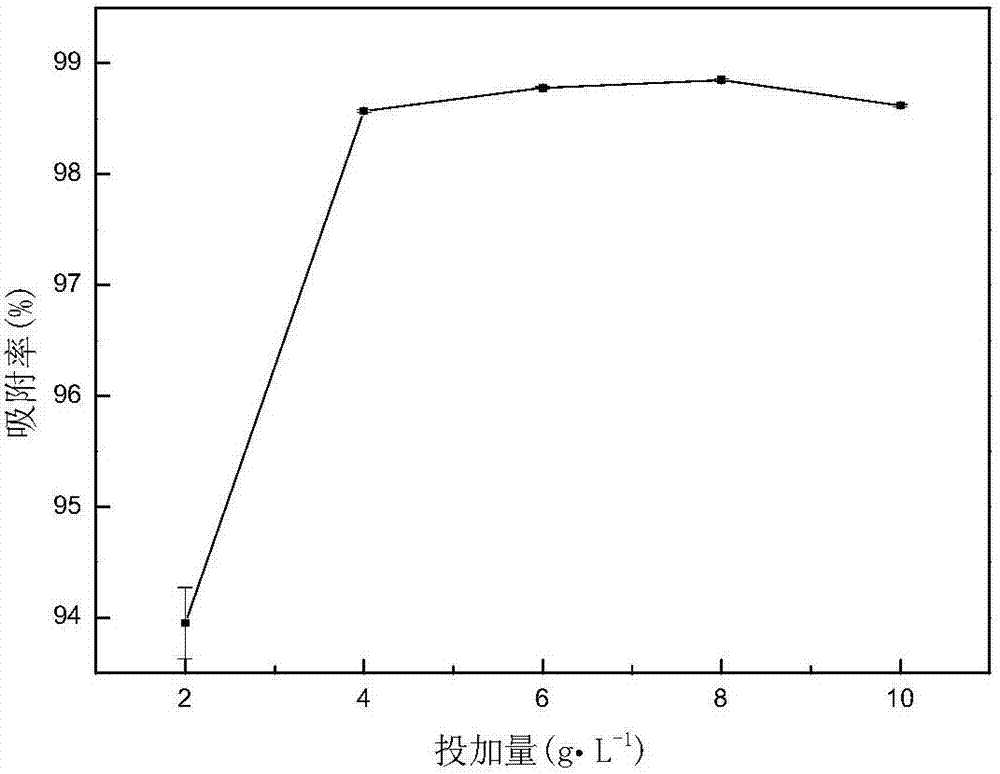

[0024] Take No. 1 sludge-based biomass hydrothermal carbon adsorbent and add it to crystal violet dye water with an initial concentration of 150mg / L. The solutions correspond to 0.05, 0.10, 0.15, 0.20, and 0.25 g of adsorbents respectively, shake and adsorb at 20°C for 24 hours, and centrifuge to separate solid and liquid. Collect the liquid into the waste container for unified disposal.

[0025] The effect of adsorbe...

example 2

[0026] Example 2: Centrifuge the sludge for preliminary dehydration, dry, grind, and sieve to 350-850 μm for later use. Weigh 50g of sludge particles, add 450ml of water, adjust the pH value of the mud-water mixture solution to 7 with 0.1mol / L HCl and NaOH solution, react at 180°C for 3h, take out the product and centrifuge to separate the solid and liquid, and then Wash several times with water, take out the solid and dry at 105°C for 24 hours to obtain No. 2 sludge-based biomass hydrothermal carbon adsorbent with a yield of 44.50%.

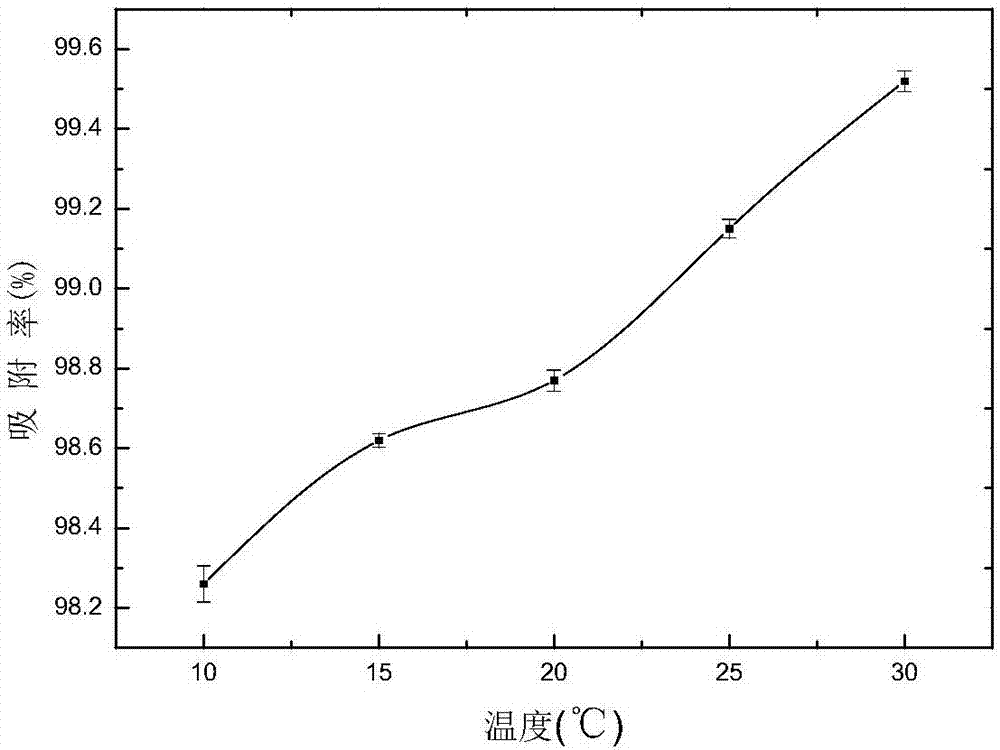

[0027] Take No. 2 sludge-based biomass hydrothermal carbon adsorbent and add it to crystal violet dye water with an initial concentration of 150mg / L. The dosage of adsorbent is 6g / L, that is, 25ml crystal violet solution corresponds to 0.15g adsorbent, respectively 10, 15, 20, 25, 30°C, shake and adsorb for 24 hours, and centrifuge to separate solid and liquid. Collect the liquid into the waste container for unified disposal.

[0028] The effe...

example 3

[0029] Example 3: Centrifuge the sludge for preliminary dehydration, dry, grind, and sieve to 350-850 μm for later use. Weigh 100g of sludge particles, add 400ml of water, adjust the pH value of the mud-water mixture solution to 9 with 0.1mol / L HCl and NaOH solution, react at 180°C for 3h, take out the product and centrifuge to separate the solid and liquid, and then After washing several times with water, the solid was taken out and dried at 105° C. for 24 hours to obtain No. 3 sludge-based biomass hydrothermal carbon adsorbent with a yield of 46.20%.

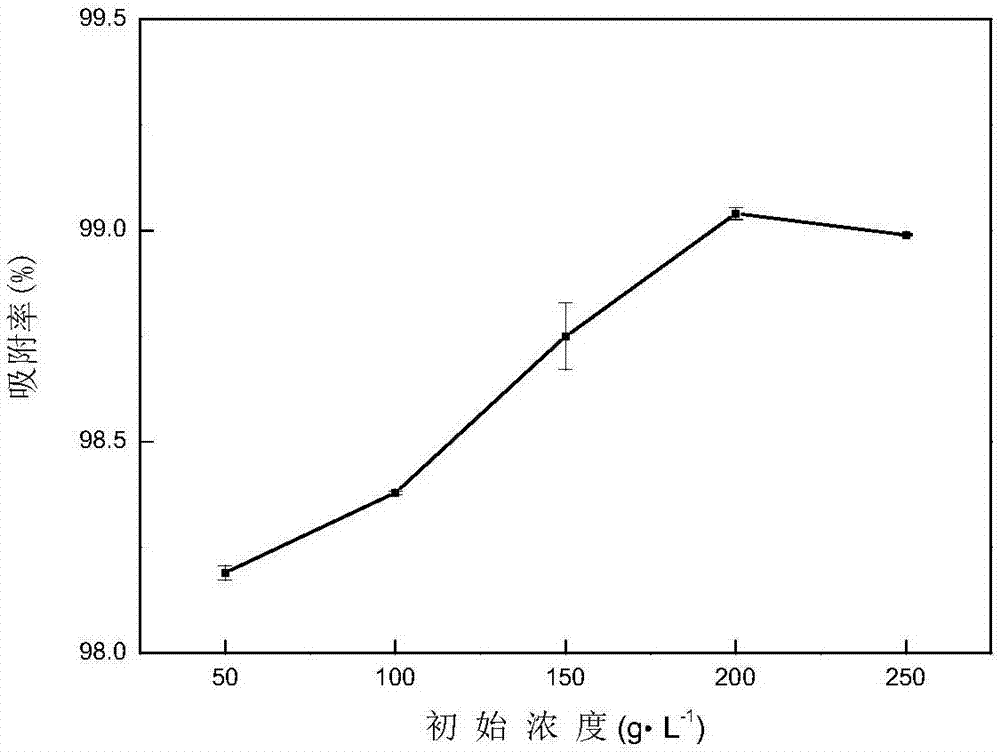

[0030] Take No. 3 sludge-based biomass hydrothermal carbon adsorbent and add it to crystal violet dye water with an initial concentration of 50, 100, 150, 200, and 250mg / L. The dosage of the adsorbent is 6g / L, that is, 25ml crystal violet solution Corresponding to 0.15g of adsorbent, shake and adsorb at 20°C for 24 hours, and centrifuge to separate solid and liquid. Collect the liquid into the waste container for unified disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com