Method for absorbing and recovering metal nickel from electroplating wastewater

A technology for electroplating wastewater and metal nickel, which is applied in the direction of improving process efficiency, etc., can solve the problems of poor operability, long time-consuming, low adsorption efficiency, etc., and achieve the effect of being suitable for large-scale application, overcoming time-consuming, and improving adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] This embodiment relates to the method for absorbing and reclaiming metal nickel from electroplating wastewater, comprising the following steps:

[0016] (1) Resin activation: Soak the resin in saturated brine for 18 to 24 hours, then drain the brine and rinse it with distilled water; then use 2% to 4% sodium hydroxide to soak for 2 to 4 hours, take it out and rinse until medium properties; finally soak in 5% hydrochloric acid for 4 to 8 hours, take it out and rinse until neutral to activate the resin to form an activated resin.

[0017] (2) Macroporous resin adsorption: Put the activated and pretreated resin into a dynamic adsorption device, and the resin dosage is 30 g / L. The height-to-diameter ratio of the dynamic adsorption device in this example is 5:1, the shape of the aeration hole is oval, the ratio of the aperture of the aeration hole to the height of the dynamic adsorption device is 1:20, and the aeration rate is 0.8m 3 / min, the resin forms a turbulent flow w...

Embodiment 2

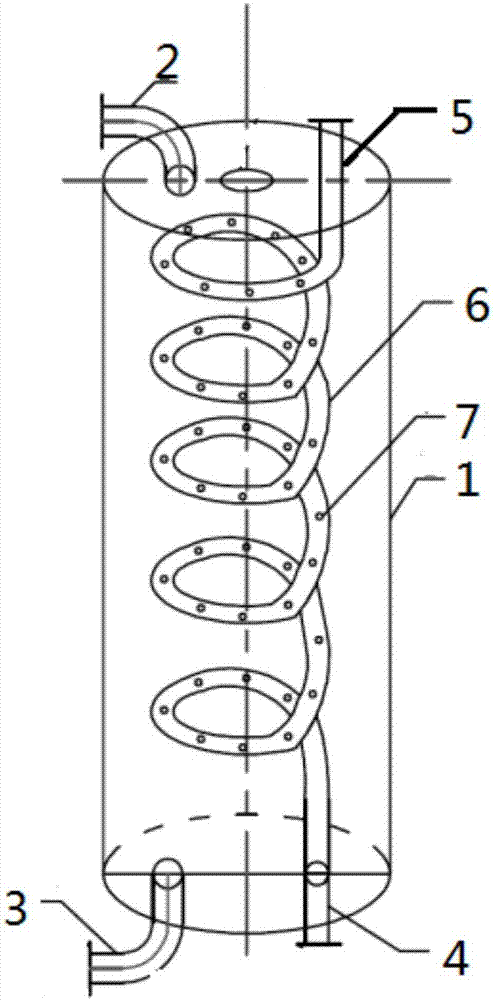

[0021] This embodiment relates to the dynamic adsorption device used in Embodiment 1, and its structure is as attached figure 1 shown.

[0022] The dynamic adsorption device comprises a column body 1, a water inlet pipe 2, an outlet pipe 3, an air inlet pipe 4, an air outlet pipe 5 and an air pipe 6; the water inlet pipe 2 and the water outlet pipe 3 are respectively arranged at two ends of the column body 1; The body 1 also has a reaction chamber in which a carboxylic acid-based cationic resin is placed; the air pipe 6 is spirally installed in the reaction chamber; several aeration holes 7 are provided on the air pipe 6; The air inlet pipe 4 and the air outlet pipe 5 are communicated through the air pipe 6; the electroplating waste water enters the column body 1 forwardly from the water inlet pipe 2, and the aeration gas enters the column body 1 reversely from the air inlet pipe 4; and the activated carboxylic acid The base cationic resin and the electroplating wastewater fl...

Embodiment 3

[0024] This embodiment relates to the method for absorbing and reclaiming metal nickel from electroplating wastewater (the basic structure of the dynamic adsorption device used in this embodiment is composed of the same as that of the dynamic adsorption device in Example 2), comprising the following steps:

[0025] (1) Resin activation: Soak the resin in saturated brine for 18-24 hours, then drain the brine and rinse it with clean water; then soak it in 2%-4% sodium hydroxide for 2-4 hours, take it out and rinse until medium properties; finally soak in 5% hydrochloric acid for 4 to 8 hours, take it out and rinse until neutral to activate the resin to form a specific resin.

[0026] (2) Macroporous resin adsorption: Put the activated and pretreated resin into a traditional static adsorption device, and the resin dosage is 80 g / L. The height-to-diameter ratio of the dynamic adsorption device in this example is 10:1, the shape of the aeration hole is oval, the ratio of the apertu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com