A kind of preparation method of ticn gradient coating

A gradient coating and coating technology, which is applied in the direction of coating, metal material coating process, solid diffusion coating, etc., can solve the problems of unstable arc current, affecting coating performance, large internal stress, etc., and achieve the elimination of interface Effects of reducing stress, reducing coefficient of friction, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

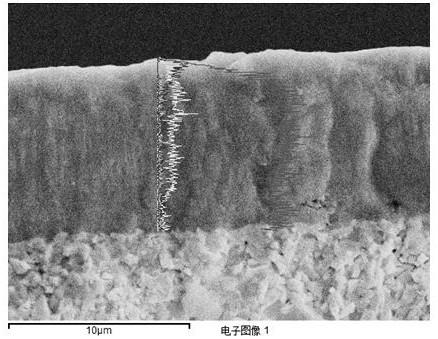

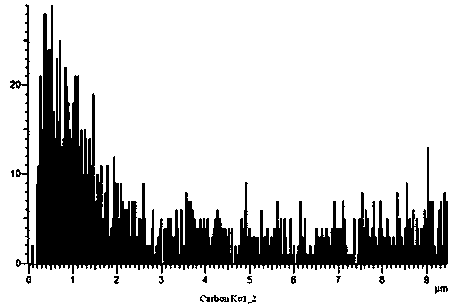

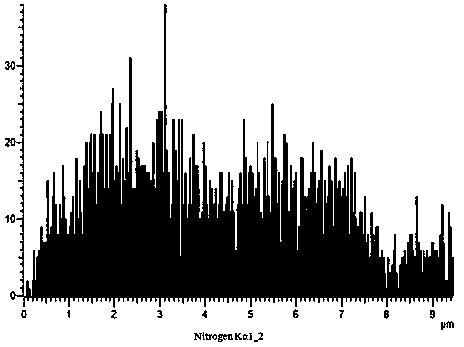

Image

Examples

Embodiment 1

[0026] A. Preparation of TiN-coated bulk

[0027] TiN was deposited on the surface of YT15 cemented carbide substrate using a multi-arc ion coating machine under the process conditions of nitrogen flow rate 360sccm, argon flow rate 40sccm, arc current 100A, pulse bias voltage 200V, duty cycle 50%, and substrate temperature 250°C. Coating, TiN coating blocks were prepared, and the coating adhesion and average friction coefficient were 48.5 N and 0.65, respectively.

[0028] B. Preparation of solid carburizing agent

[0029] According to the proportion of activated carbon: 20%, KBF4: 20%, Al: 10%, SiC: 50% (by weight percentage), the solid carburizing agent is weighed and prepared, and it is dry mixed in an ordinary ball mill for 24 hours. The speed of the ball mill is 45 r / min.

[0030] C, preparation has TiCN gradient coating

[0031] S1: Fill the graphite crucible with the mixed solid carburizing agent, and at the same time bury the TiN-coated block in the middle of the ca...

Embodiment 2

[0035] A. Preparation of TiN-coated bulk

[0036] TiN was deposited on the surface of YT15 cemented carbide substrate using a multi-arc ion coating machine under the process conditions of nitrogen flow rate 360sccm, argon flow rate 40sccm, arc current 100A, pulse bias voltage 200V, duty cycle 50%, and substrate temperature 250°C. coating, its coating adhesion and average coefficient of friction were 48.5 N and 0.65, respectively.

[0037] B. Preparation of solid carburizing agent

[0038] According to the proportion of activated carbon: 30%, KBF4: 10%, Al: 5%, SiC: 50% (in terms of weight percentage), the solid carburizing agent is weighed and prepared, and dry-mixed in an ordinary ball mill for 24 hours. The speed of the ball mill is 45 r / min.

[0039] C, preparation has TiCN gradient coating

[0040] S1: Fill the graphite crucible with the mixed solid carburizing agent, and at the same time bury the TiN-coated block in the middle of the carburizing agent powder, and then ...

Embodiment 3

[0043] A. Preparation of TiN-coated bulk

[0044] TiN was deposited on the surface of YT15 cemented carbide substrate using a multi-arc ion coating machine under the process conditions of nitrogen flow rate 360sccm, argon flow rate 40sccm, arc current 100A, pulse bias voltage 200V, duty cycle 50%, and substrate temperature 250°C. coating, its coating adhesion and average coefficient of friction were 48.5 N and 0.65, respectively.

[0045] B. Preparation of solid carburizing agent

[0046] According to the ratio of activated carbon: 25%, KBF4: 15%, Al: 7.5%, SiC: 52.5% (by weight percentage), the solid carburizing agent is weighed and prepared, and it is dry mixed in an ordinary ball mill for 24 hours. The speed of the ball mill is 45 r / min.

[0047] C, preparation has TiCN gradient coating

[0048] S1: Fill the graphite crucible with the mixed solid carburizing agent, and at the same time bury the TiN-coated block in the middle of the carburizing agent powder, and then tigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com