Preparation method of non-metallic modified oxide direct alcohol fuel cell cathode catalyst

A fuel cell cathode and oxide technology, applied in fuel cells, battery electrodes, circuits, etc., can solve problems such as poor stability, low catalyst performance, and high catalyst preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

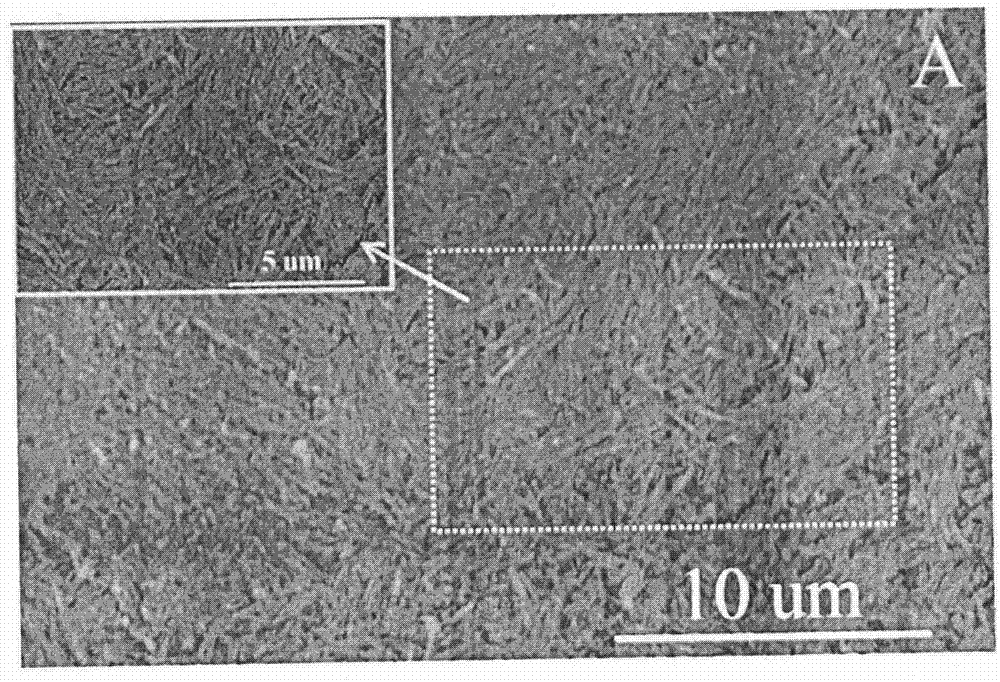

[0006] Specific embodiment one: the preparation method of nonmetal modified oxide type direct alcohol fuel cell cathode catalyst is to realize according to the following steps: 1, take cerium chloride and sodium hydroxide as raw material, deionized water is solvent, and in stainless steel high pressure Heat in the kettle at 200°C, react for 45 hours, and prepare ceria nanowires by hydrothermal method; 2. Disperse the product obtained in step 1 and phosphorus ionic liquid in deionized water, and ultrasonically 1 hour to obtain a uniform dispersion. 3. Fill the Put the crucible of the slurry in a water bath at 80° C. to evaporate to dryness. 4. Heat the product obtained in step 3 in a tube furnace at 300° C. for 2 hours under argon gas.

specific Embodiment approach 2

[0007] Embodiment 2: This embodiment is different from Embodiment 1 in that the reaction time of step 1 is 30 hours; its steps and parameters are the same as Embodiment 1.

specific Embodiment approach 3

[0008] Embodiment 3: This embodiment is different from Embodiment 1 and Embodiment 2 in that the reaction temperature in Step 1 is changed to 180°C. Other steps and parameters are the same as those in the specific embodiment 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com