Technology for producing glutathione by fermenting saccharomyces cerevisiae

A technology of Saccharomyces cerevisiae and glutathione, applied in fermentation, microbial-based methods, peptides, etc., can solve problems such as consumption of glutathione to protect cells, decrease in glutathione production, and inhibition of bacterial growth, etc., to achieve Sustains long-term oxidative stimulation, promotes the accumulation of GSH, and alleviates the effects of yeast growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

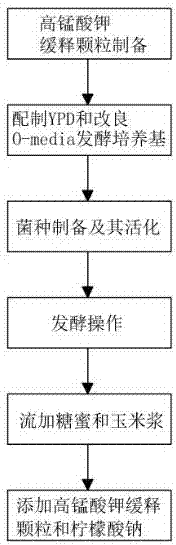

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Batch fermentation experiment using O-media medium

[0036] This embodiment adopts the traditional culture method:

[0037] First, the yeast culture was inoculated into a fermenter (10 L) containing traditional O-media medium at a volume ratio of 5% for fermentation.

[0038] Fermentation conditions: culture temperature 30°C, initial pH 6.0, dissolved oxygen concentration 30%;

[0039] Counting from the time of fermentation, after 120 hours of fermentation, the wet weight of Saccharomyces cerevisiae cells in the fermentation broth was detected to reach 45.9 g / L, and the accumulation of GSH reached 0.47 g / L.

[0040] Determination method of GSH: Chromatographic conditions: GSH is determined by HPLC method, high performance liquid chromatography (Shimadzu LC10A), reversed-phase C18 chromatographic column (Hanbon Sci. & Tech). Phosphate buffer solution and methanol were mixed at a volume ratio of 9:1 as the mobile phase, the flow rate was 1 mL / min, and the dete...

Embodiment 2

[0041] Example 2 Batch fermentation test using improved O-media medium

[0042] On the basis of Example 1, the traditional O-media medium in the fermenter was replaced with an improved O-media medium, and other fermentation conditions were the same as in Example 1.

[0043] After 120 h of fermentation, the wet weight of Saccharomyces cerevisiae cells in the fermentation broth reached 41.5 g / L, and the GSH accumulation reached 0.83 g / L.

Embodiment 3

[0044] Embodiment 3 molasses fed-batch experiment

[0045] Real-time monitoring of the carbon source concentration in the fermented liquid during the fermentation process of Example 2 found that when the fermentation was carried out for 16 hours, the glucose was exhausted. Therefore, on the basis of the experiment in Example 2, 16 hours after the start of fermentation, the carbon source was added to the The molasses was fed into the fermentation broth at a constant speed for 72 hours (that is, the feeding was stopped 88 hours after the fermentation started), and the other fermentation conditions were the same as in Example 2.

[0046] The experiment was divided into three groups. The feeding amount of molasses was 0.5 g / L / h, 1.5 g / L / h and 2.0 g / L / h respectively, and they were numbered 1-3 in sequence. Yeast cell wet weight and GSH accumulation, the results are shown in Table 1:

[0047] Table 1 Results of molasses fed-batch experiment

[0048] serial number Cell ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com