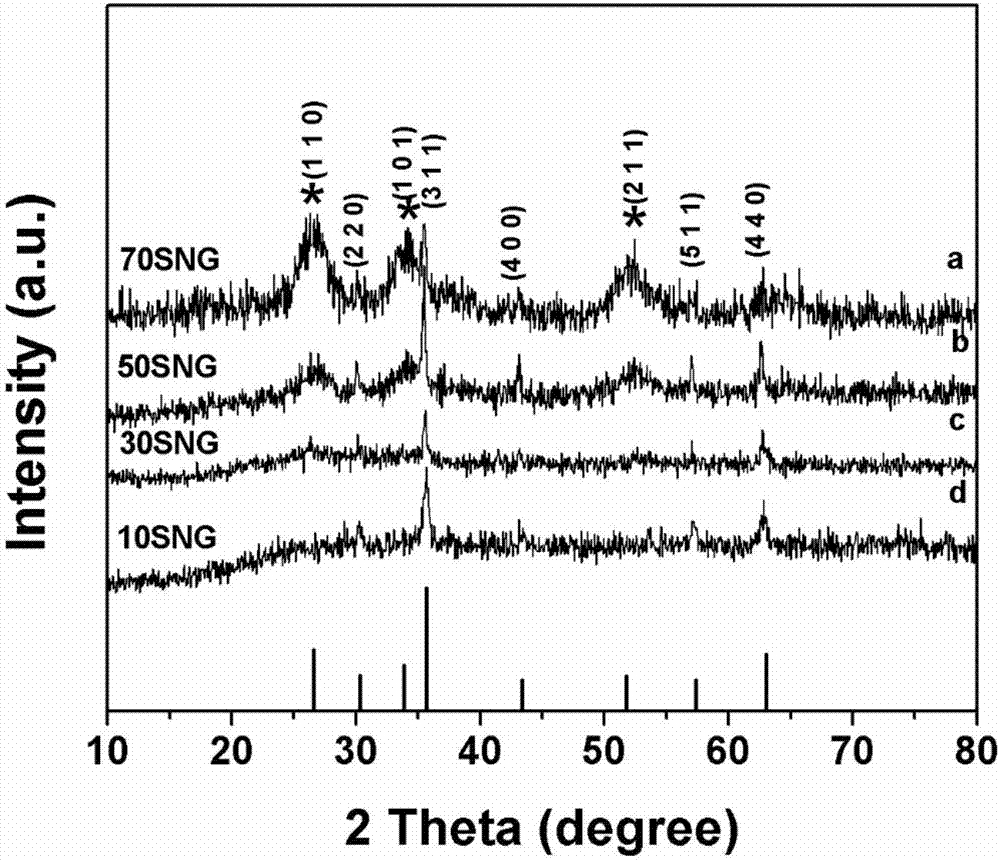

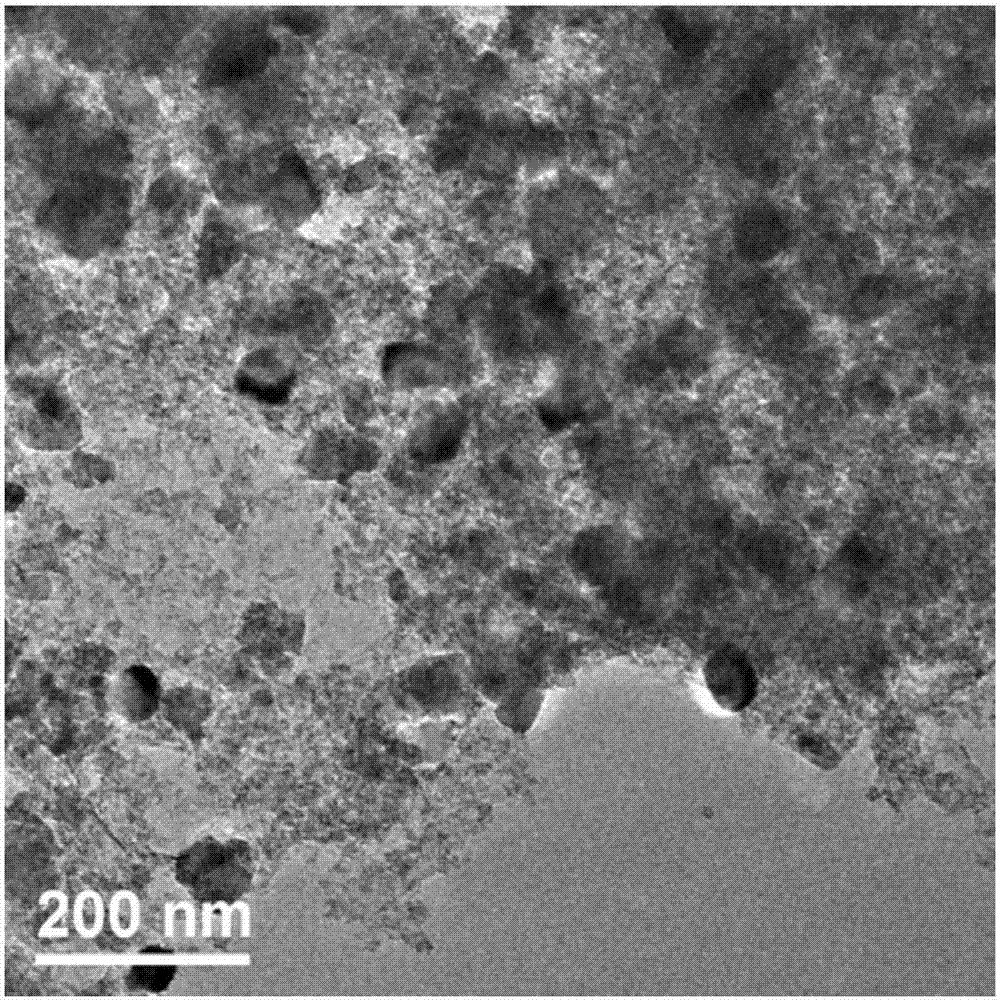

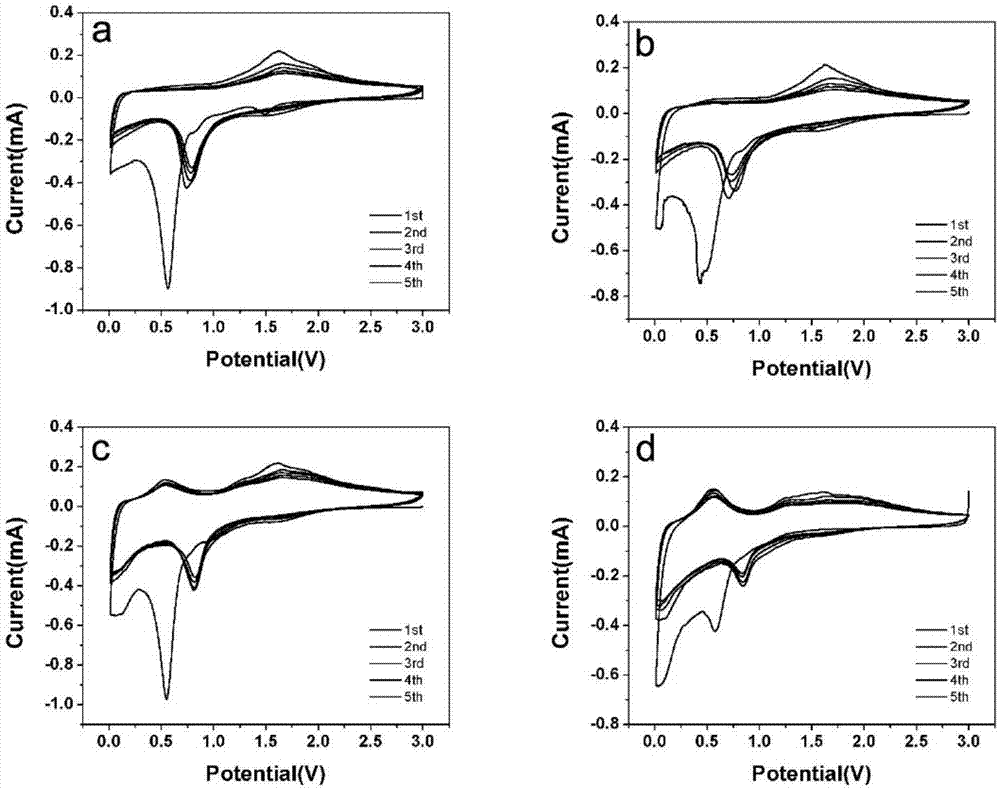

Tin dioxide/nickel ferrite/graphene composite material as well as preparation method and application thereof

A technology of graphene composite and composite materials, which is applied in the direction of secondary batteries, electrochemical generators, structural parts, etc., can solve the problems of unsuitability for large-scale industrial production, excessive resource consumption, and harsh synthesis conditions. The method is environmentally friendly, the particles are uniform, and the shape is controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In the first step, 0.34 g of nickel nitrate hexahydrate and 0.93 g of iron nitrate nonahydrate were dissolved in 25 mL of deionized water.

[0036] In the second step, 0.045 g of stannous chloride dihydrate was dissolved in 25 mL of ethylene glycol solution.

[0037] In the third step, 100 mg of graphite oxide was dissolved in 25 mL of deionized water and ultrasonically dispersed to form a uniformly dispersed single-layer graphene oxide mixed solution.

[0038] In the fourth step, slowly add the mixed solution obtained in the first step and the second step into the single-layer graphene oxide mixed solution obtained in the third step and continue stirring for 30 minutes to form a mixed solution 1.

[0039] Step 5: Add 4 g of urea to the mixed solution 1, and continue stirring for 30 minutes to obtain the mixed solution 2.

[0040] In the sixth step, the mixed solution 2 was transferred to a 100 mL stainless steel reactor and reacted at 180° C. for 20 h.

[0041] In the ...

Embodiment 2

[0048] In the first step, 0.26 g of nickel nitrate hexahydrate and 0.73 g of iron nitrate nonahydrate were dissolved in 25 mL of deionized water.

[0049] In the second step, 0.135 g of stannous chloride dihydrate was dissolved in 25 mL of ethylene glycol solution.

[0050] In the third step, 100 mg of graphite oxide was dissolved in 25 mL of deionized water and ultrasonically dispersed to form a uniformly dispersed single-layer graphene oxide mixed solution.

[0051] In the fourth step, slowly add the mixed solution obtained in the first step and the second step into the single-layer graphene oxide mixed solution obtained in the third step and continue stirring for 30 minutes to form a mixed solution 1.

[0052] Step 5: Add 4 g of urea to the mixed solution 1, and continue stirring for 30 minutes to obtain the mixed solution 2.

[0053] In the sixth step, the mixed solution 2 was transferred to a 100 mL stainless steel reactor and reacted at 180° C. for 20 h.

[0054] In th...

Embodiment 3

[0060] In the first step, 0.19 g of nickel nitrate hexahydrate and 0.52 g of iron nitrate nonahydrate were dissolved in 25 mL of deionized water.

[0061] In the second step, 0.225 g of stannous chloride dihydrate was dissolved in 25 mL of ethylene glycol solution.

[0062] In the third step, 100 mg of graphite oxide was dissolved in 25 mL of deionized water and ultrasonically dispersed to form a uniformly dispersed single-layer graphene oxide mixed solution.

[0063] In the fourth step, slowly add the mixed solution obtained in the first step and the second step into the single-layer graphene oxide mixed solution obtained in the third step and continue stirring for 30 minutes to form a mixed solution 1.

[0064] Step 5: Add 4 g of urea to the mixed solution 1, and continue stirring for 30 minutes to obtain the mixed solution 2.

[0065] In the sixth step, the mixed solution 2 was transferred to a 100 mL stainless steel reactor and reacted at 180° C. for 20 h.

[0066] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com