Preparation method and application of hydrophilic polyether sulfone ultrafiltration membrane

A technology of polyethersulfone ultrafiltration membrane and hydrophilic polymer, which is applied in separation methods, chemical instruments and methods, membranes, etc., and can solve the problems of unsuitable large-scale applications, ultrafiltration membrane pollution, and high price of graphene oxide. problem, to achieve the effect of increasing flux recovery rate, changing water flux, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

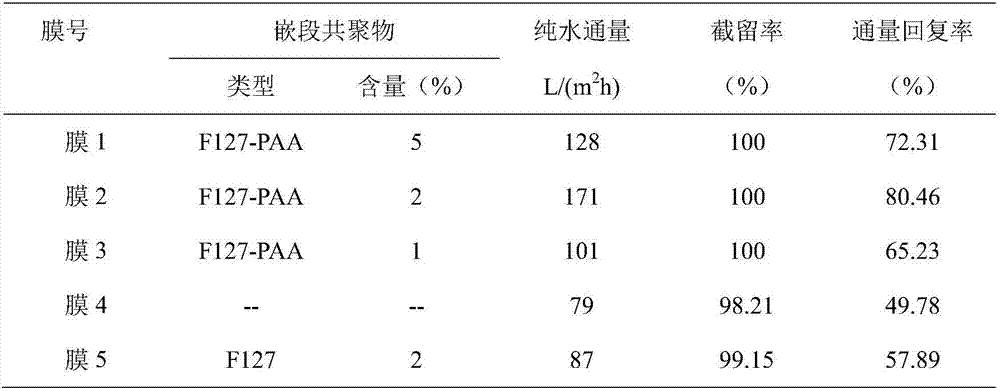

[0033] Embodiment 1: the preparation of hydrophilic polyethersulfone ultrafiltration membrane (membrane 1)

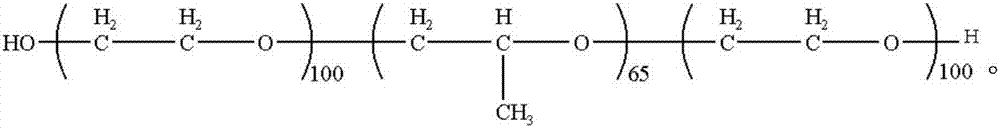

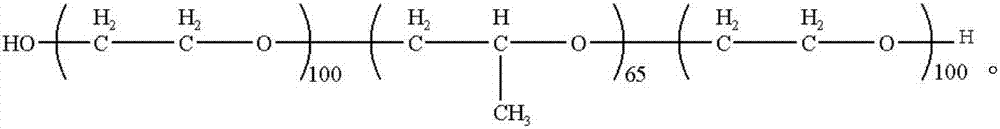

[0034] Weigh 10g of triblock copolymer F127, dissolve in 40ml of dichloromethane, and prepare solution a; weigh 0.04g of 4-dimethylaminopyridine and 1.7g of triethylamine, mix them, dissolve in solution a to obtain solution b; Weigh 0.82g of 2-bromopropionyl bromide and dissolve it in 60ml of dichloromethane to prepare solution c; slowly add solution c to solution b within 60min, and stir vigorously, and keep the reaction system at room temperature for 24h; After the end, the reaction mixture d was washed with alkali and pickled respectively, and dehydrated to obtain a clear solution e; the clear solution e was removed by rotary evaporation to obtain the macroinitiator F127-Br; weigh 0.5g of the macroinitiator Dissolve F127-Br and 3.98g of tert-butyl acrylate in 24ml of methanol, stir until completely dissolved, add 1.34mg of PMEDTA and 0.174mg of copper bromide, and st...

Embodiment 2

[0037]Embodiment 2: the preparation of hydrophilic polyethersulfone ultrafiltration membrane (membrane 2)

[0038] Weigh 10g of triblock copolymer F127, dissolve in 40ml of dichloromethane, and prepare solution a; weigh 0.04g of 4-dimethylaminopyridine and 1.7g of triethylamine, mix them, dissolve in solution a to obtain solution b; Weigh 0.82g of 2-bromopropionyl bromide and dissolve it in 60ml of dichloromethane to prepare solution c; slowly add solution c to solution b within 60min, and stir vigorously, and keep the reaction system at room temperature for 24h; After the end, the reaction mixture d was washed with alkali and pickled respectively, and dehydrated to obtain a clear solution e; the clear solution e was removed by rotary evaporation to obtain the macroinitiator F127-Br; weigh 0.5g of the macroinitiator Dissolve F127-Br and 3.98g of tert-butyl acrylate in 24ml of methanol, stir until completely dissolved, add 1.34mg of PMEDTA and 0.174mg of copper bromide, and sti...

Embodiment 3

[0041] Embodiment 3: the preparation of hydrophilic polyethersulfone ultrafiltration membrane (membrane 3)

[0042] Weigh 10g of triblock copolymer F127, dissolve in 40ml of dichloromethane, and prepare solution a; weigh 0.04g of 4-dimethylaminopyridine and 1.7g of triethylamine, mix them, dissolve in solution a to obtain solution b; Weigh 0.82g of 2-bromopropionyl bromide and dissolve it in 60ml of dichloromethane to prepare solution c; slowly add solution c to solution b within 60min, and stir vigorously, and keep the reaction system at room temperature for 24h; After the end, the reaction mixture d was washed with alkali and pickled respectively, and dehydrated to obtain a clear solution e; the clear solution e was removed by rotary evaporation to obtain the macroinitiator F127-Br; weigh 0.5g of the macroinitiator Dissolve F127-Br and 3.98g of tert-butyl acrylate in 24ml of methanol, stir until completely dissolved, add 1.34mg of PMEDTA and 0.174mg of copper bromide, and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com