Method for preparing calixarene-modified magnetic nano-adsorbent and adsorbing low-concentration uranium with calixarene-modified magnetic nano-adsorbent

A magnetic nanometer and adsorbent technology, applied in chemical instruments and methods, radioactive purification, other chemical processes, etc., can solve the problems of complicated processing technology, high production cost, high processing cost, and achieve good adsorption effect and stable adsorption effect. , the effect of high adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0029] The preparation of the adsorbent provided by the invention and the specific steps of adsorbing low-concentration uranium are:

[0030] (1) FeCl with a molar ratio of 1:2 2 4H 2 O and FeCl 3 ·6H 2 O weighed and placed in a beaker to dissolve, then pour the solution into a three-necked flask, add a certain amount of distilled water dissolved in a certain amount of 4-sulfonylcalix[6]arene hydrate, stir quickly and evenly, and stir at 60°C for a certain period of time, Adjust the pH to 11 with 1mol / L NaOH solution, raise the temperature to 80°C, and stir for a certain period of time under the protection of nitrogen. After crystallization at room temperature, it was washed several times with distilled water.

[0031] (2) dry. The product obtained in step (1) was vacuum-dried at 50°C for 24 hours to obtain 4-sulfonylcalix[6]arene-modified Fe 3 o 4 Magnetic material adsorbent-MFS.

[0032] (3) Grind the product obtained in step (2) into powder, put it into a clean plas...

Embodiment 1

[0034] IV Example 1 The preparation of the adsorbent provided by the patent of the present invention:

[0035] (1) Fe 3 o 4 Preparation of Magnetic Materials

[0036] FeCl 2 4H 2 O and FeCl 3 ·6H 2 O is weighed in a molar ratio of 1:2 and placed in a beaker for dissolution, then the solution is poured into a three-necked flask, stirred evenly, stirred at 60°C for a certain period of time, and adjusted to pH 11 with 1mol / L NaOH solution. The temperature was raised to 80°C, and the reaction was stirred for a certain period of time under the protection of nitrogen. After crystallization at room temperature, it was washed several times with distilled water, and dried in a vacuum oven at 50°C for 24 hours. The obtained product was ground into powder, put into a clean plastic centrifuge tube, and stored in a refrigerator.

[0037] (2) 4-sulfonylcalix[6]arene-modified magnetic nano-Fe 3 o 4 --Preparation of MFS

[0038] FeCl 2 4H 2 O and FeCl 3 ·6H 2 O is weighed and pl...

Embodiment 2

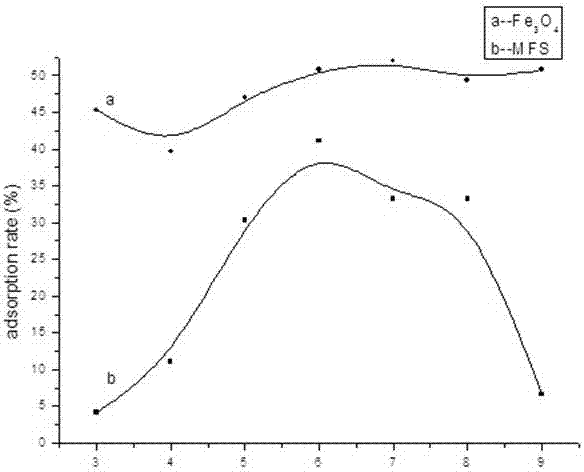

[0039] Example 2, pipette 100 mL of uranium solution with an initial concentration of 2.5 mg / L in a 200 mL Erlenmeyer flask, and adjust the pH of the solution to 3, 4, 5, 6, 7, 8, 9 in triplicate, respectively. Dosing 0.003 g Fe 3 o 4 Magnetic material adsorbent / 0.003 g The adsorbent provided by the patent of the present invention is shaken and cultivated in a water bath culture shaker at room temperature, from Fe 3 o 4 Add the solution to start timing, shake and adsorb for 1 hour, and measure the concentration of uranium remaining in it. When pH is 3-9, Fe 3 o 4 The adsorption rates of MFS are 45.26%, 39.68%, 47.03%, 50.76%, 51.98%, 49.38%, 50.76%; 6.64%. It can be seen from this that Fe 3 o 4 When the pH is 7, the maximum adsorption rate is 51.98%, and the adsorbent provided by the patent of the present invention reaches the maximum adsorption rate of 41.13% when the pH is 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com