Amorphous bismuth oxide composite photocatalyst, preparation method and application method

A bismuth oxide, amorphous technology, applied in the field of photocatalyst preparation, can solve problems such as low NO degradation rate, and achieve the effects of increasing crystallinity, simple preparation and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

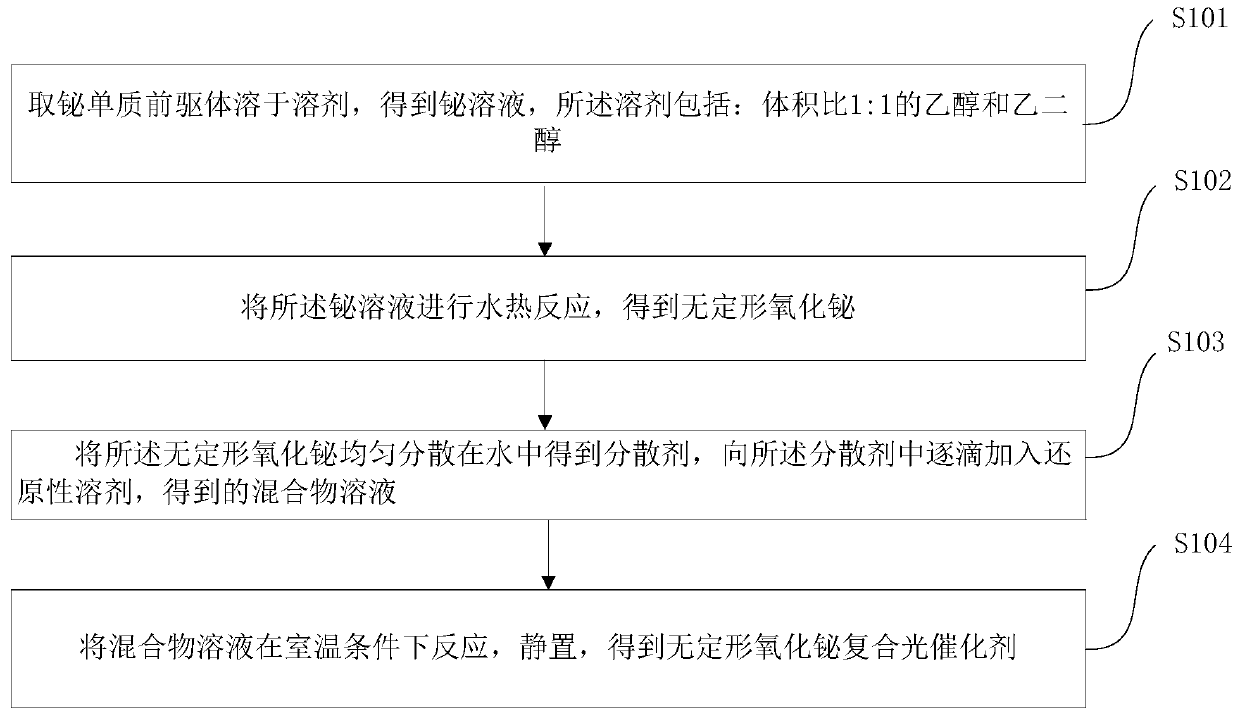

Method used

Image

Examples

Embodiment 1

[0075] 6mol(NO 3 ) 3 ·5H 2 O was dissolved in 40 ml of bismuth solution with a volume ratio of ethanol and ethylene glycol of 1:1, and the mixture was heat-treated at a heating temperature of 160° C. and the heat treatment time was 3 hours to obtain an amorphous bismuth oxide solid. Disperse 1g of amorphous bismuth oxide in 30ml of distilled water at room temperature, add dropwise 30mL of 1mmol / L sodium borohydride solution, add 1g of PVP as a stabilizer, and react for 1h to obtain the product in a test tube for later use.

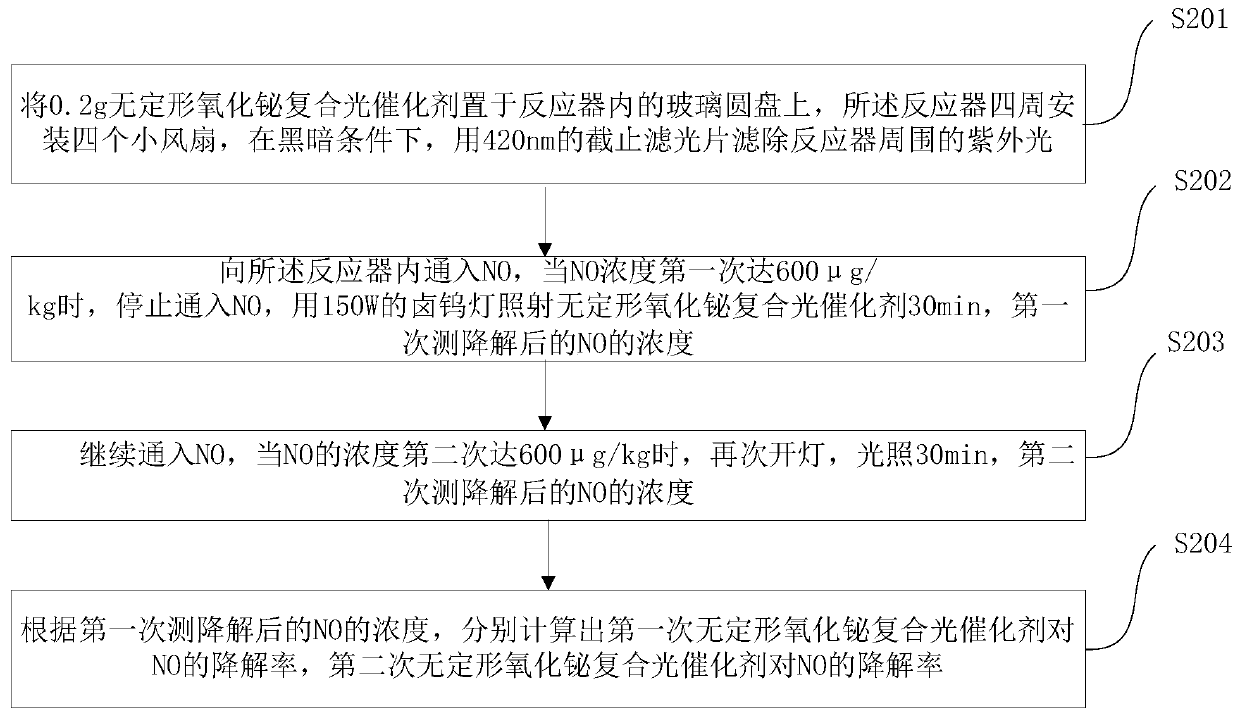

[0076] The amorphous bismuth oxide composite photocatalyst with a reducing agent concentration of 1 mmol / L prepared in the examples of this application degrades NO. The specific process is: at a relative humidity of 60%, an oxygen content of 21%, and a flow of NO gas flow of 3.3L / L min. Under the condition that the initial concentration of NO is 600μg / kg, 0.2g of the amorphous bismuth oxide composite photocatalyst prepared in the example is placed on a glass d...

Embodiment 2

[0078] 6mol(NO 3 ) 3 ·5H 2 O was dissolved in 40 ml of bismuth solution with a volume ratio of ethanol and ethylene glycol of 1:1, and the mixture was heat-treated at a heating temperature of 160° C. and the heat treatment time was 3 hours to obtain an amorphous bismuth oxide solid. Disperse 1g of amorphous bismuth oxide in 30ml of distilled water at room temperature, add dropwise 30mL of 3mmol / L sodium borohydride solution, add 1g of PVP as a stabilizer, react for 1h, and put the product in a test tube for later use.

[0079] Degradation of NO by the amorphous bismuth oxide composite photocatalyst prepared in the example of this application with a reducing agent concentration of 3 mmol / L is the same as that of Example 1 to calculate the degradation of NO by the amorphous bismuth oxide composite photocatalyst prepared in the example of this application The rate is 23.4%. It can be seen that bismuth element can activate the NO degradation rate of amorphous bismuth oxide, and the st...

Embodiment 3

[0081] 6mol(NO 3 ) 3 ·5H 2 O was dissolved in 40 ml of bismuth solution with a volume ratio of ethanol and ethylene glycol of 1:1, and the mixture was heat-treated at a heating temperature of 160° C. and the heat treatment time was 3 hours to obtain an amorphous bismuth oxide solid. Disperse 1g of amorphous bismuth oxide in 30ml of distilled water at room temperature, add 1g of PVP as a stabilizer, react for 1h, and add 30ml of 5mmol / L sodium borohydride solution dropwise to obtain the product and put it in a test tube for later use.

[0082] Degradation of NO by the amorphous bismuth oxide composite photocatalyst prepared in the example of this application with a reducing agent concentration of 5mmol / L is the same as that of Example 1 and calculated to obtain the degradation of NO by the amorphous bismuth oxide composite photocatalyst prepared in the example of this application The rate is 37.1%. It can be seen that bismuth element can activate the NO degradation rate of amorphou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com