High-temperature brazing filler metal for foam silver filling based on metal tin and preparing method of high-temperature brazing filler metal

A technology of high-temperature solder and foamed silver, which is applied in metal processing equipment, metal material coating technology, welding equipment, etc., can solve problems such as inability to achieve fitness, and achieve the effect of good impact resistance and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The invention provides a high-temperature solder based on tin-filled foamed silver and a preparation method thereof. The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0041]A method for preparing high-temperature solder based on metal tin filling foamed silver, comprising:

[0042] (1) smelting to obtain silver-aluminum alloy, and cutting into alloy flakes of appropriate size;

[0043] (2) cleaning step (1) processed alloy flakes, removing surface stains and drying;

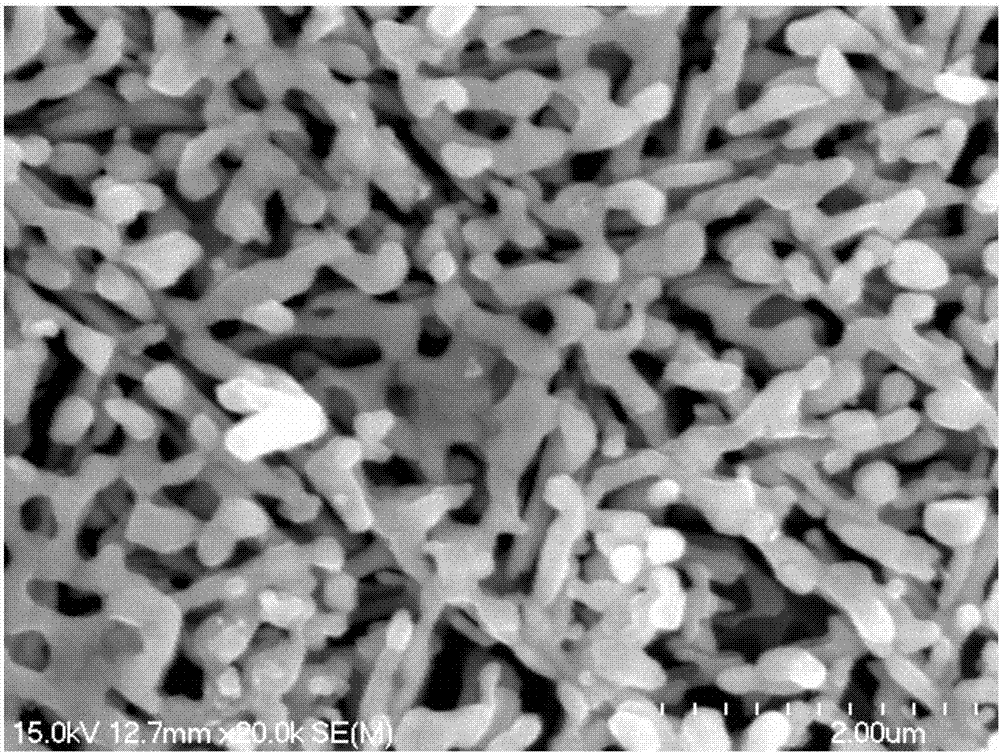

[0044] (3) Preparing an appropriate proportion of corrosive solution, and obtaining a foamed silver sheet by a dealloying method, the foamed silver sheet has certain pores;

[0045] (4) the foamed silver flake that cleaning step (3) obtains, removes surface stain, and dry stand-by;

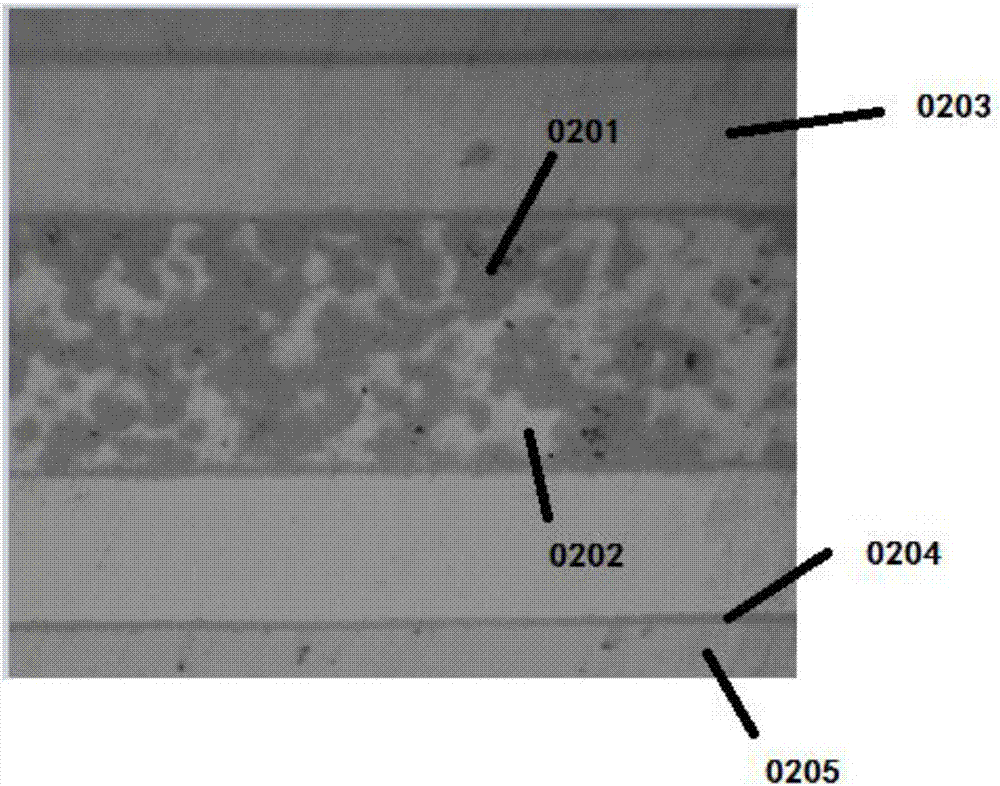

[0046] (5) Print solder paste of appropriate size and thickness on the foamed silver sheet by screen printing, and then reflow to obtain a high-temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com