Preparation method of MoS2 nanosheets adopting two-dimensional nanostructures

A two-dimensional nanostructure and nanosheet technology, applied in nanotechnology, molybdenum sulfide, etc., to achieve low cost, good crystallinity, and controllable layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

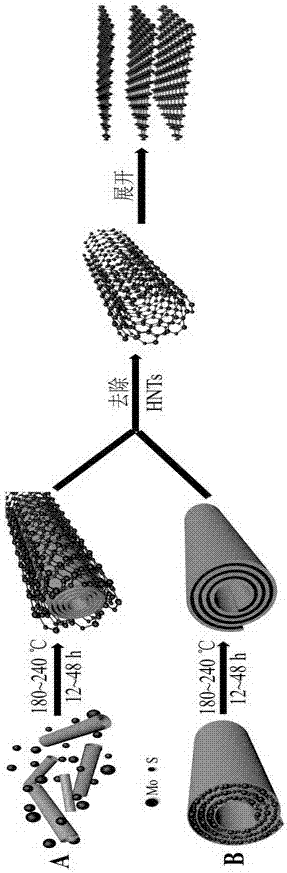

Method used

Image

Examples

example 1

[0042] 1. Preparation of MoS 2 Nanosheets:

[0043] Put 3.8 g of ammonium molybdate and 6.6 g of thiourea into 70 mL of distilled water, and stir them under magnetic force at 30 °C to dissolve them to obtain ammonium molybdate concentration of 0.05 g / mL, thiourea concentration of 0.09 g / mL and molybdenum atoms Add 2 mL of HNTs powder at 60 °C to the above mixing system with a molar ratio of 1:4 to the sulfur atom, continue to stir to make the solid-liquid mix evenly, and transfer it to a stainless steel autoclave lined with polytetrafluoroethylene , reacted at 180 °C, 5 rpm for 48 h.

[0044] After the reaction, the system was naturally cooled to room temperature, and the product was washed with 20% hydrofluoric acid aqueous solution and 20% hydrochloric acid aqueous solution to remove template HNTs, and then washed with deionized water and absolute ethanol for 3 ~5 times, centrifuge, filter, dry at 50 °C for 12 h, and collect the black product after grinding.

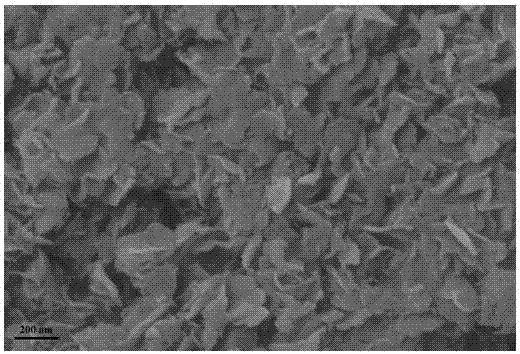

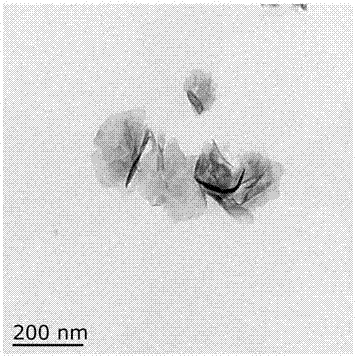

[0045] Such...

example 2

[0049] 1. Preparation of MoS 2 Nanosheets:

[0050] Put 3.8 g of ammonium molybdate and 4.7 g of thioacetamide into 70 mL of distilled water, and stir them under magnetic force at 40 °C to dissolve them to obtain a concentration of ammonium molybdate of 0.05 g / mL and a concentration of thioacetamide of 0.07 g / mL. mL of a solution with a molar ratio of molybdenum atoms and sulfur atoms of 1:3, add 2 mL of HNTs powder at 80 °C to the above mixing system, continue to stir to make the solid-liquid mix evenly, and transfer it to a polytetrafluoroethylene-lined stainless steel In a high-pressure reactor, the reaction was carried out at 220 °C and 10 rpm for 24 h.

[0051] After the reaction, the system was naturally cooled to room temperature, and the product was washed with 30% hydrofluoric acid aqueous solution and 30% hydrochloric acid aqueous solution respectively to remove the template, and then washed with deionized water and absolute ethanol for 3~ Five times, centrifuge, f...

example 3

[0056] 1. Preparation of MoS 2 Nanosheets:

[0057] Put 4.3 g of sodium molybdate and 3.3 g of sodium sulfide in 70 mL of distilled water, and stir them under magnetic force at 60 °C to dissolve them to obtain a concentration of sodium molybdate of 0.06 g / mL, a concentration of sodium sulfide of 0.05 g / mL and molybdenum atoms Add 2 mL of 100 °C HNTs powder to the above mixed system with a molar ratio of 1:2 to the sulfur atom, continue to stir to make the solid-liquid mix evenly, and transfer it to a stainless steel autoclave lined with polytetrafluoroethylene , reacted at 240 °C, 15 rpm for 12 h.

[0058] After the reaction, the system was naturally cooled to room temperature, and the product was washed with 40% hydrofluoric acid aqueous solution and 38% hydrochloric acid aqueous solution respectively to remove the template, and then washed with deionized water and absolute ethanol for 3~ Five times, centrifuge, filter, dry at 80 °C for 24 h, and collect the product after g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com