ZrO2 (zirconium oxide) and HfO2 (hafnium oxide)-codoped microcrystalline glass of dentistry

A glass-ceramic and dental technology, applied in dentistry, dental preparations, dental prostheses, etc., can solve the problems of mechanical properties and stability not as good as international leading products, achieve stable process, easy to obtain raw materials, and avoid devitrification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

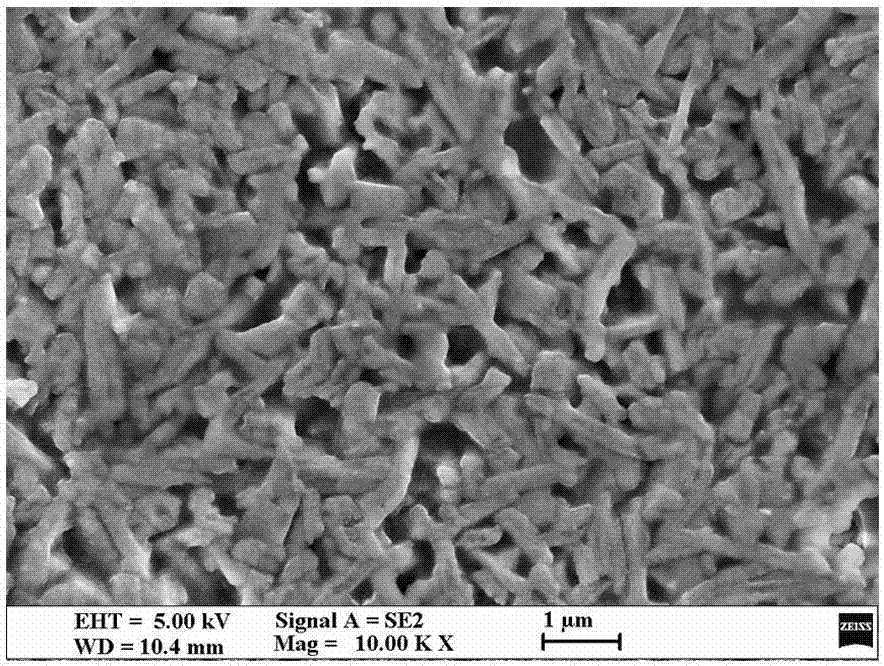

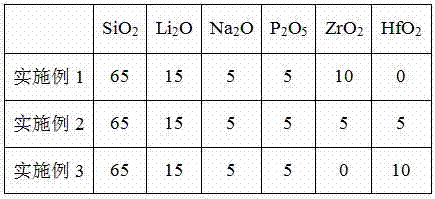

[0043] Embodiment 1: preparation of material and performance test result

[0044] According to the ratio of each component in Table 1, a certain amount of analytically pure raw material (SiO 2 , Li 2 CO 3 、Na 2 CO 3 , NH 4 h 2 PO 4 , ZrO 2 and HfO 2 ), use a ball mill to mix evenly for 8 hours; then put the powder into a platinum crucible, place it in the air atmosphere of a box-type resistance furnace, and heat it at 4°C / min to 330°C and 850°C for 1 hour each to remove nitrogen and carbon , continue to heat up to 1500°C and keep it warm for 1 hour; then, take out the crucible, pour the melt into deionized water to quench, and dry to obtain fragments of glass melt; ball mill again, and the powder is directly heated to 1500°C / 1 hour for remelting ;Cast the remelted molten glass into a mold preheated at 550°C, quickly put it into a resistance furnace, heat it at 500°C for 10 minutes, then immediately rise to 550°C and hold it for 30 minutes, then cool with the furnace. ...

Embodiment 2

[0045] Embodiment 2: preparation of material and performance test result

[0046] According to the ratio of each component in Table 1, a certain amount of analytically pure raw material (SiO 2 , Li 2 CO 3 、Na 2 CO 3 , NH 4 h 2 PO 4 , ZrO 2 and HfO 2 ), use a ball mill to mix evenly for 8 hours; then put the powder into a platinum crucible, place it in the air atmosphere of a box-type resistance furnace, and heat it at 4°C / min to 330°C and 850°C for 1 hour each to remove nitrogen and carbon , continue to heat up to 1500°C and keep it warm for 1 hour; then, take out the crucible, pour the melt into deionized water to quench, and dry to obtain fragments of glass melt; ball mill again, and the powder is directly heated to 1500°C / 1 hour for remelting ;Cast the remelted molten glass into a mold preheated at 550°C, quickly put it into a resistance furnace, heat it at 500°C for 10 minutes, then immediately rise to 550°C and hold it for 30 minutes, then cool with the furnace. ...

Embodiment 3

[0047] Embodiment 3: preparation of material and performance test result

[0048] According to the ratio of each component in Table 1, a certain amount of analytically pure raw material (SiO 2 , Li 2 CO 3 、Na 2 CO 3 , NH 4 h 2 PO 4 , ZrO 2 and HfO 2 ), use a ball mill to mix evenly for 8 hours; then put the powder into a platinum crucible, place it in the air atmosphere of a box-type resistance furnace, and heat it at 4°C / min to 330°C and 850°C for 1 hour each to remove nitrogen and carbon , continue to heat up to 1500°C and keep it warm for 1 hour; then, take out the crucible, pour the melt into deionized water to quench, and dry to obtain fragments of glass melt; ball mill again, and the powder is directly heated to 1500°C / 1 hour for remelting ;Cast the remelted molten glass into a mold preheated at 550°C, quickly put it into a resistance furnace, heat it at 500°C for 10 minutes, then immediately rise to 550°C and hold it for 30 minutes, then cool with the furnace. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com