Silicon nitride-resin double continuous phase composite ceramic material and preparation method and application thereof

A technology of composite ceramics and bicontinuous phases, applied in the field of materials, can solve the problems of lack of rod-like grain structure and difficulty in achieving strength, etc., and achieve the effects of good machinability, simple process, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) The mixed powder comprising silicon nitride powder and sintering aid powder (yttrium oxide is used as the sintering aid, and the sintering aid accounts for 5% of the mass of the powder) is press-molded under a pressure of 12 MPa using a press molding process , and then perform cold isostatic pressing under a pressure of 280MPa to obtain a green body;

[0055] (2) The green body was placed in a nitrogen atmosphere furnace, sintered at 1700° C., and kept for 2 hours. At this time, the bending strength of the ceramic body was measured to be 212.2 MPa, and the porosity was 39.5%.

[0056] (3) Place the ceramic green body in 5% ethanol solution of silane coupling agent (γ-methacryloxypropyltrimethoxysilane), soak for 3 hours, then take it out and dry it in the air, and dry it at 120°C for 30min , to obtain a surface-treated ceramic green body;

[0057] (4) Place the ceramic green body in PMMA resin, carry out atmospheric pressure infiltration treatment, and take it out ...

Embodiment 2

[0062] (1) The mixed powder comprising silicon nitride powder and sintering aid powder (as yttrium oxide, the sintering aid accounts for 5% of the mass of the powder) is formulated into a 50wt% slurry by using the pouring molding process. As a solvent, silicon nitride ceramic green bodies are then produced through a casting process;

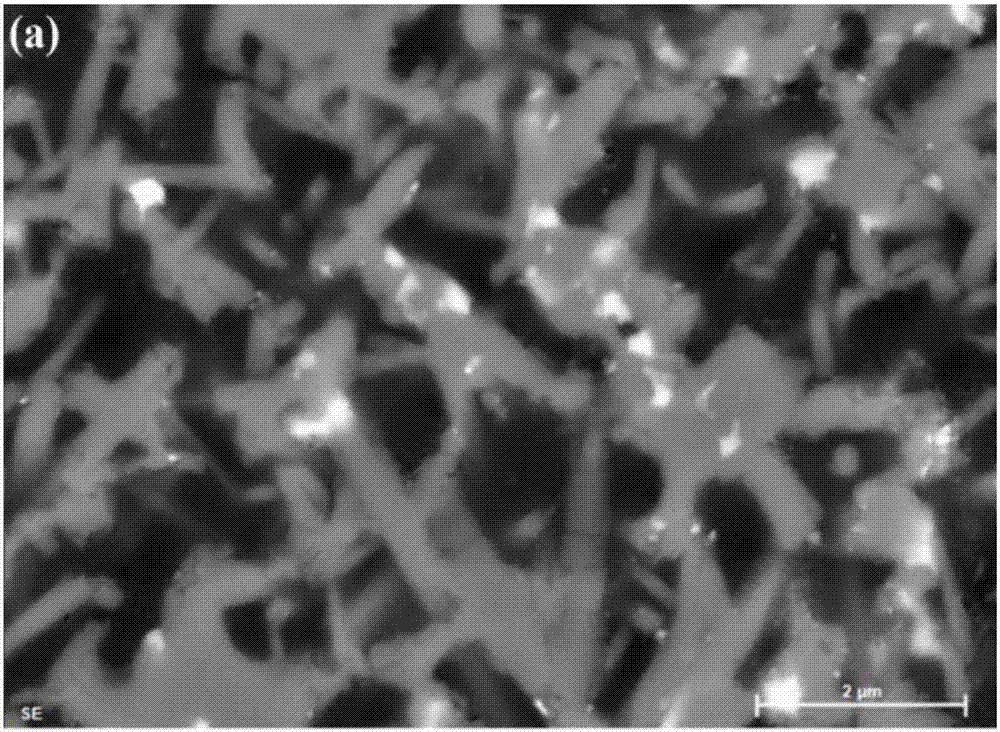

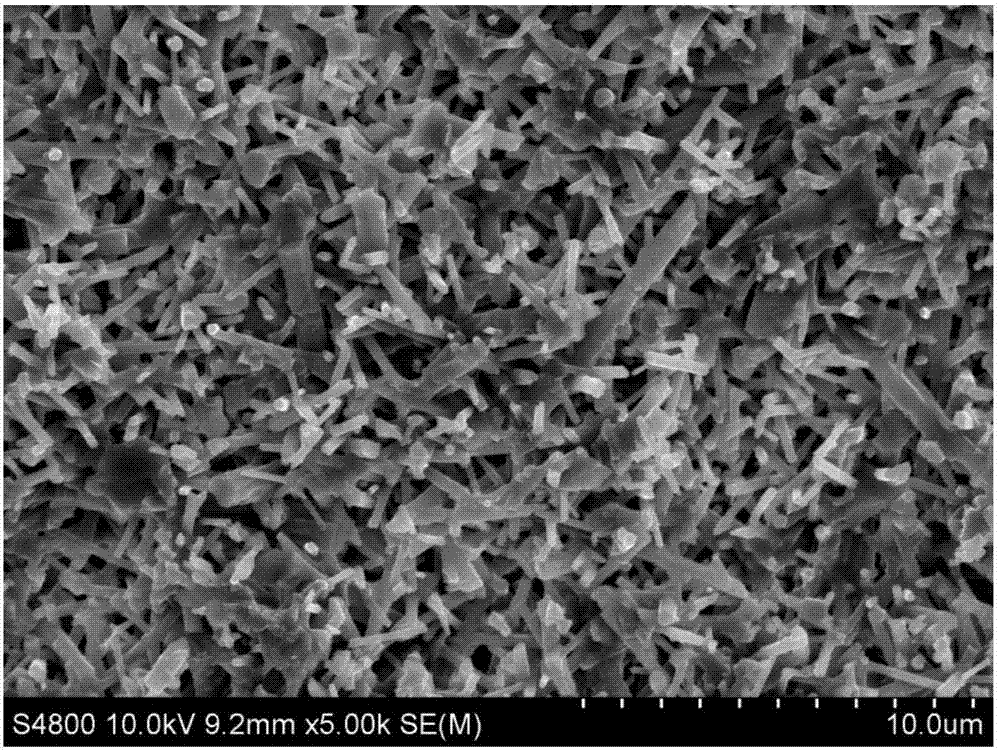

[0063] (2) The ceramic green body was placed in a nitrogen atmosphere furnace, sintered at 1700° C., and kept for 2 hours. At this time, the bending strength of the ceramic body was measured to be 171.75 MPa, and the porosity was 49.3%. The microscopic morphology of the obtained porous silicon nitride ceramics is as follows: figure 2 shown. from figure 2 It can be seen that porous silicon nitride has a uniform long rod-shaped grain morphology, and a uniform and connected porous structure. The connected porous structure is conducive to the penetration and compounding of the resin material, and the long rod-shaped grain structure is conducive ...

Embodiment 3

[0069] (1) The mixed powder comprising silicon nitride powder and sintering aid powder (yttrium oxide is used as sintering aid, accounting for 5% of the mass of the powder) is prepared into a 60wt% slurry by using the pouring molding process. As a solvent, silicon nitride ceramic green bodies are then produced through a casting process;

[0070] (2) The ceramic green body was placed in a nitrogen atmosphere furnace, sintered at 1700° C., and kept for 2 hours. At this time, the bending strength of the ceramic body was measured to be 262.25 MPa, and the porosity was 45.1%.

[0071] (3) Place the ceramic green body in 5% ethanol solution of silane coupling agent (γ-methacryloxypropyltrimethoxysilane), soak for 3 hours, then take it out and dry it in the air, and dry it at 120°C for 30min , to obtain a surface-treated ceramic green body;

[0072] (4) Place the ceramic green body in PMMA resin, carry out atmospheric pressure infiltration treatment, and take it out after 24 hours. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com