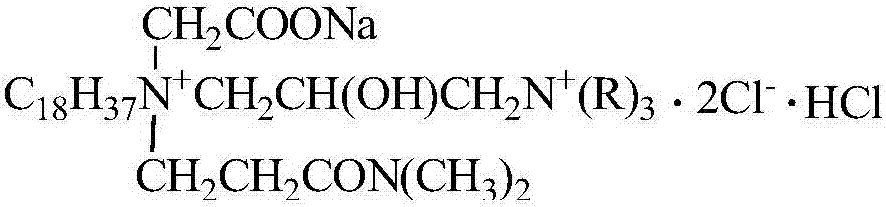

Dicationic and monoanionic tertiary amide asphalt emulsifier and preparation method thereof

An asphalt emulsifier and dication technology, which is applied in the field of dication monoanion tertiary amide type asphalt emulsifier and its preparation, can solve the problems of high irritation and unfavorable health of production workers, so as to increase hydrophilicity and hydration layer and the effect of interfacial charge layer enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

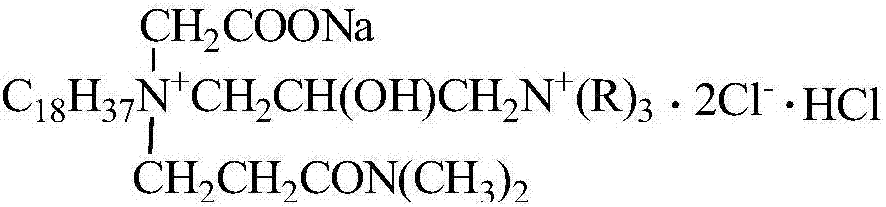

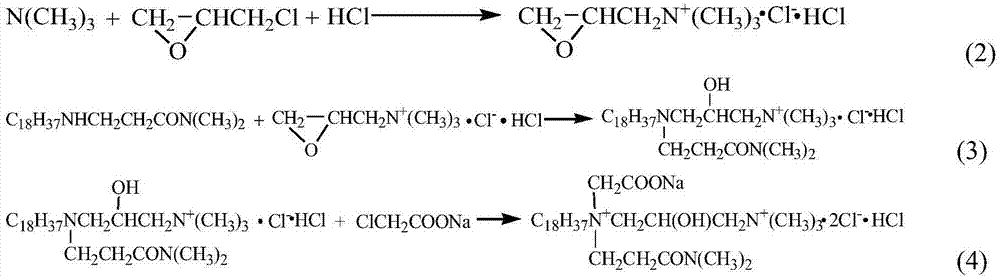

[0062] In one embodiment, the present invention provides a kind of preparation method of dication monoanion tertiary amide type asphalt emulsifier, comprising the following steps:

[0063] (1) Mix octadecylamine, alcohol solvent and N,N-dimethylacrylamide to obtain reaction intermediate I, and intermediate I is C 18 h 37 NHCH 2 CH 2 CON(CH 3 ) 2 ;

[0064] (2) Mix low carbon number tertiary amine, industrial hydrochloric acid and epichlorohydrin, react to obtain reaction intermediate II, low carbon number tertiary amine is trimethylamine aqueous solution, triethylamine or triethanolamine aqueous solution, intermediate II is R is methyl (-CH 3 ), ethyl (-C 2 h 5 ) or hydroxyethyl (-C 2 h 4 OH);

[0065] (3) The prepared reaction intermediate II is added dropwise in the reaction intermediate I, and the mixed reaction obtains the reaction intermediate III, and the intermediate III is

[0066] R is methyl (-CH 3 ), ethyl (-C 2 h 5 ) or hydroxyethyl (-C 2 h 4 OH...

Embodiment 1

[0085] (1) Preparation of dicationic monoanionic tertiary amide type asphalt emulsifier:

[0086] 1) Add 269.5g octadecylamine, 260g isopropanol in the reactor, heat and stir to dissolve. Then gradually add 104.1g of N,N-dimethylacrylamide, and stir at 70°C for 3h.

[0087] 2) In another reactor, add 193.1g 33% (mass fraction) trimethylamine aqueous solution, gradually add 131.2g 30% (mass fraction) industrial hydrochloric acid, then gradually add 97.1g epichlorohydrin, stir and react at 50°C for 2.5h, Reaction intermediate A was obtained.

[0088] 3) The prepared reaction intermediate A was added dropwise to the synthesis product in the above step 1), and stirred at 70° C. for 2 h.

[0089] 4) 42.4g sodium hydroxide was dissolved in 80.0g water to obtain sodium hydroxide aqueous solution, 100.2g chloroacetic acid was dissolved in 200.0g water to obtain chloroacetic acid aqueous solution; sodium hydroxide aqueous solution was added dropwise in chloroacetic acid aqueous solut...

Embodiment 2

[0099] (1) Preparation of dicationic monoanionic tertiary amide type asphalt emulsifier:

[0100] 1) Add 269.5g octadecylamine, 260g isopropanol in the reactor, heat and stir to dissolve. Then gradually add 104.1g N,N-dimethylacrylamide, and stir the reaction at 70°C for 3h.

[0101] 2) Add 109.1g triethylamine to another reactor, gradually add 131.2g 30% (mass fraction) industrial hydrochloric acid, then gradually add 97.1g epichlorohydrin, stir and react at 50°C for 2.5h, and obtain reaction intermediate B.

[0102] 3) The prepared reaction intermediate B was added dropwise to the synthesis product in the above step 1), and stirred at 65° C. for 3 h.

[0103] 4) 42.4g sodium hydroxide was dissolved in 80.0g water to obtain sodium hydroxide aqueous solution, 100.2g chloroacetic acid was dissolved in 200.0g water to obtain chloroacetic acid aqueous solution; sodium hydroxide aqueous solution was added dropwise in chloroacetic acid aqueous solution to obtain sodium chloroaceti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com