Synthesis of waterborne epoxy curing agent and preparation method of waterborne epoxy curing agent

A water-based epoxy and curing agent technology, applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of short application period of anti-corrosion paint, improve hydrophilicity, improve construction performance, enhance phase capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

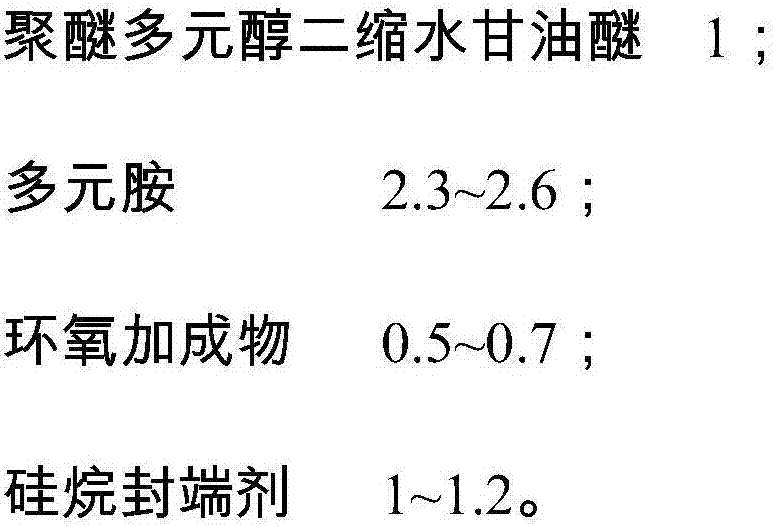

[0037] The preparation method of water-based curing agent is completed according to the following steps:

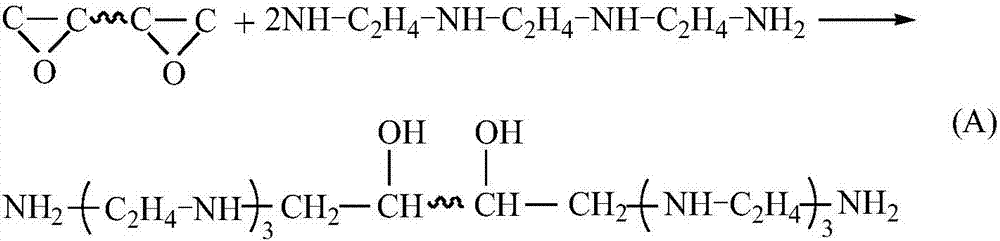

[0038] 1) Introducing a hydrophilic segment: use polypropylene glycol diglycidyl ether (epoxy value 0.28 to 0.36) to react with triethylenetetramine, and drop triethylenetetramine into a three-necked flask equipped with a condenser at a temperature of 60°C In the middle, after the dropwise addition is completed, the temperature is controlled at 65°C, the rotation speed is 50-100r / min, and the reaction is performed for 1-2 hours. The measured amine value is 530±20mgKOH / g. The recommended molar ratio of triethylenetetramine to polypropylene glycol diglycidyl ether is 2.3-2.6:1.

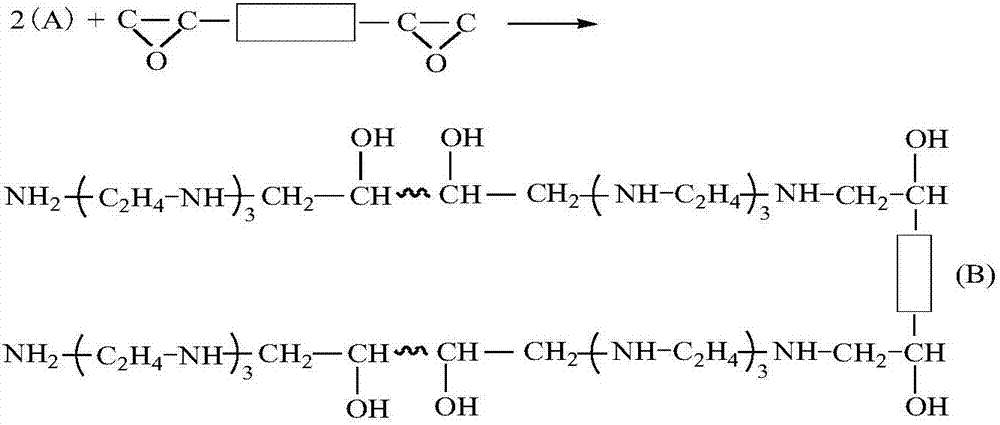

[0039] 2) Introduce epoxy resin for modification: in the aforementioned reaction device, drop epoxy adducts in a molar ratio of 0.5-0.7, (the epoxy adducts are bisphenols with a mass ratio of 1:1 A mixture of epoxy resin and propylene glycol methyl ether.), control the reaction temperature at 65 °...

Embodiment 1

[0046] Polyether polyol diglycidyl ether and triethylenetetramine were selected for addition reaction to prepare an intermediate containing a hydrophilic segment. The reaction temperature was 65° C. and the reaction time was 2 hours. The molar ratio of triethylenetetramine to polyether polyol diglycidyl ether is 2.2:1. Then drop epoxy adduct in 0.5-0.7 by molar ratio, (this epoxy adduct is the mixture of bisphenol A type epoxy resin and propylene glycol methyl ether according to mass ratio 1:1.) Control reaction temperature At 65°C, the reaction was continued for about 3 hours after the dropwise addition was completed. Adjust the solid content of the aforementioned reaction product to 50% with propylene glycol methyl ether, which is a water-based epoxy curing agent.

[0047] Use this curing agent to prepare a water-based zinc-rich primer, spray it on the surface-treated steel plate for containers, test performance: bake in an oven at 50°C for 10 minutes, observe water stains ...

Embodiment 2

[0049] Polyether polyol diglycidyl ether and triethylenetetramine were selected for addition reaction to prepare an intermediate containing a hydrophilic segment. The reaction temperature was 65° C. and the reaction time was 2 hours. The molar ratio of triethylenetetramine to polyether polyol diglycidyl ether is 2.2:1. Then drop the epoxy adduct in a molar ratio of 0.5-0.7, (the epoxy adduct is a mixture of bisphenol A type epoxy resin and propylene glycol methyl ether according to a mass ratio of 1:1.), control the reaction The temperature was 65°C, and the reaction was continued for 3 hours after the dropwise addition was completed. Finally, it is capped with a capping agent. The material molar ratio (chain-extended product of amino-terminated intermediate / phenyl glycidyl ether) was 5 / 7, and the reaction was carried out at 100° C. for 2 hours. Also adjust the solid content to 50% with propylene glycol methyl ether to obtain a blocked water-based epoxy curing agent.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com