Graphene/cast nylon composite material and preparation method thereof

A composite material and casting nylon technology, which is applied in the field of composite materials to achieve the effects of shortened distance, enhanced bonding force and densified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

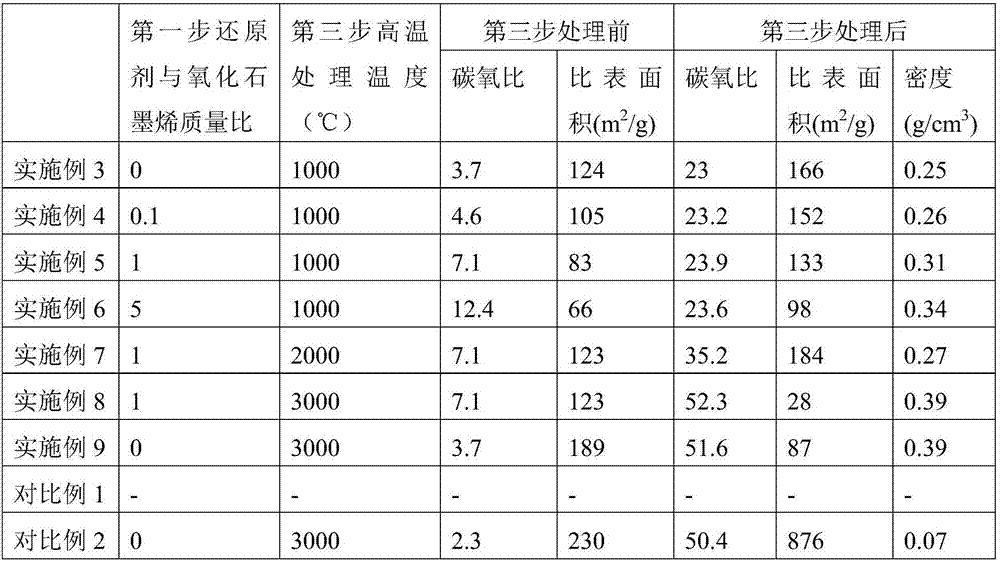

[0024] (1) drying the monolayer graphene oxide dispersion by atomization drying method to obtain graphene oxide microspheres, the atomization temperature is 130°C;

[0025] (2) placing the graphene oxide microspheres obtained in step (1) in hydrazine hydrate vapor, and reducing them for 1 hour at 60° C. to obtain reduced graphene oxide microspheres;

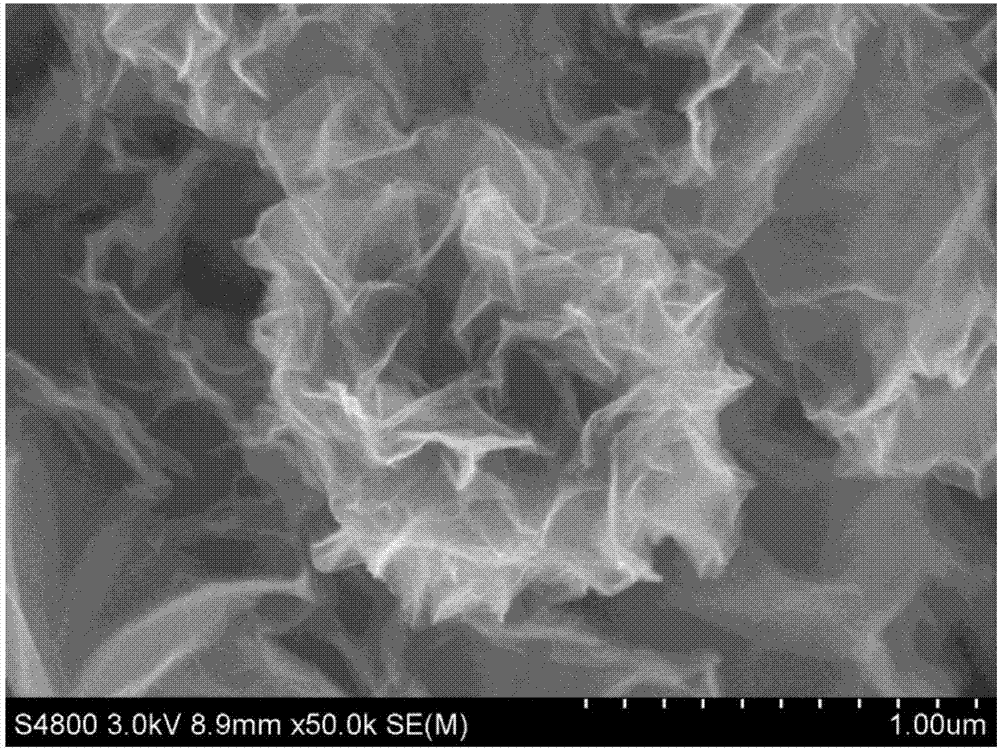

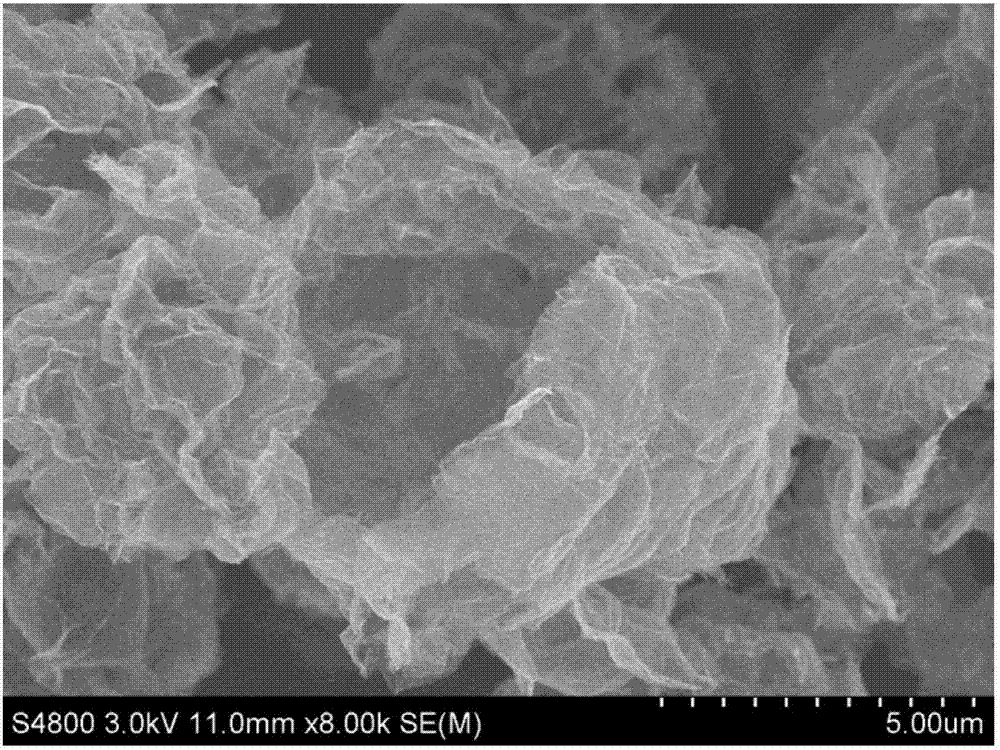

[0026] (3) Putting the reduced graphene oxide microspheres obtained in step (2) into a tube furnace, continuously feeding nitrogen, and raising the temperature to 1000° C., and keeping it warm for 1 hour to obtain paper ball-shaped graphene microspheres;

[0027] (4) Add 0.2 parts of paper-like graphene microspheres to 100 parts of molten caprolactam monomer, stir and heat up to 120°C, remove moisture by distillation under reduced pressure, then add 0.15 parts of sodium hydroxide, and heat up to 140°C, After vacuum distillation and dehydration for 30 minutes, the temperature was raised to 155°C;

[0028] (5) Add 0.35 parts of co...

Embodiment 2

[0031] (1) drying the monolayer graphene oxide dispersion by atomization drying method to obtain graphene oxide microspheres, the atomization temperature is 130°C;

[0032](2) placing the graphene oxide microspheres obtained in step (1) in hydrazine hydrate vapor, and reducing them for 1 hour at 90° C. to obtain reduced graphene oxide microspheres;

[0033] (3) Putting the reduced graphene oxide microspheres obtained in step (2) into a tube furnace, continuously feeding nitrogen, and raising the temperature to 1000° C., and keeping it warm for 1 hour to obtain paper ball-shaped graphene microspheres;

[0034] (4) Add 0.2 parts of paper-like graphene microspheres to 100 parts of molten caprolactam monomer, stir and heat up to 120°C, remove moisture by distillation under reduced pressure, then add 0.15 parts of sodium hydroxide, and heat up to 140°C, After vacuum distillation and dehydration for 30 minutes, the temperature was raised to 155°C;

[0035] (5) Add 0.35 parts of coc...

Embodiment 3

[0038] (1) drying the monolayer graphene oxide dispersion by atomization drying method to obtain graphene oxide microspheres, the atomization temperature is 130°C;

[0039] (2) placing the graphene oxide microspheres obtained in step (1) in hydrazine hydrate vapor, and reducing them for 24 hours at 90° C. to obtain reduced graphene oxide microspheres;

[0040] (3) Putting the reduced graphene oxide microspheres obtained in step (2) into a tube furnace, continuously feeding nitrogen, and raising the temperature to 1000° C., and keeping it warm for 1 hour to obtain paper ball-shaped graphene microspheres;

[0041] (4) Add 0.2 parts of paper-like graphene microspheres to 100 parts of molten caprolactam monomer, stir and heat up to 120°C, remove moisture by distillation under reduced pressure, then add 0.15 parts of sodium hydroxide, and heat up to 140°C, After vacuum distillation and dehydration for 30 minutes, the temperature was raised to 155°C;

[0042] (5) Add 0.35 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com