A kind of manufacturing method of odorless rubber material

A technology of rubber materials and production methods, which is applied in the field of rubber materials, can solve problems such as people's adverse effects on the body and feel uncomfortable, and achieve the effects of reducing odor emission, improving flow problems, and enhancing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

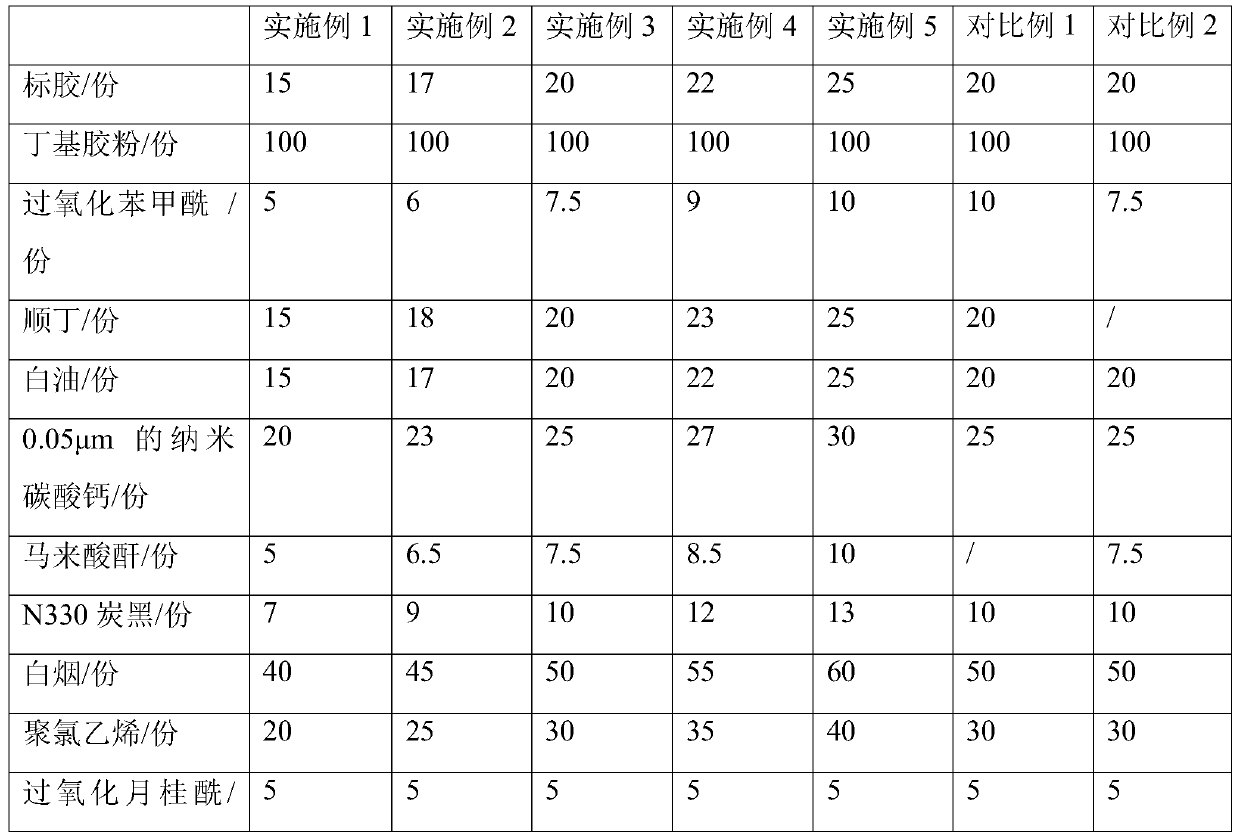

Examples

Embodiment 1

[0037] A kind of odorless rubber material is prepared through the following steps:

[0038] Step 1: Take standard rubber, solution-polymerized styrene-butadiene rubber and butyl rubber powder according to the data corresponding to Example 1 in Table 1, and mix them at room temperature to make styrene-butadiene rubber. Put the initiator for graft polymerization of styrene-butadiene rubber into the internal mixer and directly add it into the rubber emulsion, obtain modified styrene-butadiene rubber under the conditions of 135°C, rotor speed 40r / min and reaction time 3min, and modify the styrene-butadiene rubber Rubber made into powder;

[0039] Step 2: According to the data corresponding to Example 1 in Table 1, the other raw materials except step 1 were weighed, and then mixed with modified styrene-butadiene rubber;

[0040] Step 3: After uniform mixing, six basic processes of mastication, kneading, calendering, extrusion, molding and vulcanization are carried out at 120° C. t...

Embodiment 2

[0042] Each raw material was weighed according to the data corresponding to Example 2 in Table 1. Adopt the method described in embodiment 1 to prepare odorless rubber material.

Embodiment 3

[0044] Each raw material was weighed according to the data corresponding to Example 3 in Table 1. Adopt the method described in embodiment 1 to prepare odorless rubber material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com