Preparation method of car carpet material with self-adhesive foam adhesive

A car carpet, self-adhesive technology, applied in the direction of adhesives, vehicle parts, adhesive types, etc., can solve the problems of non-self-adhesive carpet backing, secondary air pollution in the car, etc., to reduce safety hazards, low density, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

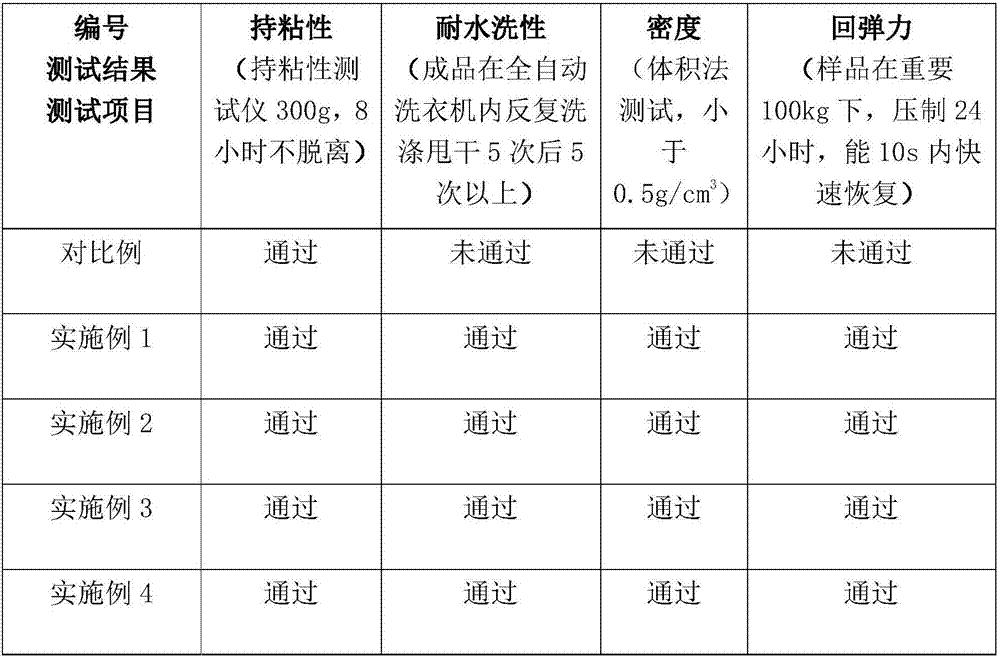

Examples

Embodiment 1

[0019] First adopt emulsion method to synthesize acrylate emulsion: concrete steps are (1) dissolving of emulsion, under normal temperature in reactor, nonylphenol polyoxyethylene ether, sodium dodecylbenzenesulfonate are dissolved in deionized water, Stir continuously to form an emulsifier solution; (2) Add butyl acrylate, butyl methacrylate, and methacrylic acid monomers to the emulsifier solution, stir quickly and evenly, then start to reduce the stirring speed, and gradually heat up to 80°C, After the solution reacts with blue light, add ammonium persulfate aqueous solution dropwise. After the ammonium persulfate aqueous solution is added dropwise, the temperature rises to 85°C, and the reaction ends after 2 hours of heat preservation; (3) cool the reaction product to 30°C, add ammonia water to adjust When the pH value reaches neutral, the acrylic emulsion can be obtained by discharging.

[0020] The natural rubber emulsion uses sodium pentachlorophenate low-ammonia latex ...

Embodiment 2

[0024] First adopt emulsion method to synthesize acrylate emulsion: concrete steps are (1) dissolving of emulsion, under normal temperature in reactor, nonylphenol polyoxyethylene ether, sodium dodecylbenzenesulfonate are dissolved in deionized water, Stir continuously to form an emulsifier solution; (2) Add butyl acrylate, butyl methacrylate, and methacrylic acid monomers to the emulsifier solution, stir quickly and evenly, then start to reduce the stirring speed, and gradually heat up to 80°C, After the solution reacts with blue light, add ammonium persulfate aqueous solution dropwise. After the ammonium persulfate aqueous solution is added dropwise, the temperature rises to 85°C, and the reaction ends after 2 hours of heat preservation; (3) cool the reaction product to 30°C, add ammonia water to adjust When the pH value reaches neutral, the acrylic emulsion can be obtained by discharging.

[0025] The natural rubber emulsion uses sodium pentachlorophenate low-ammonia latex ...

Embodiment 3

[0029] First adopt emulsion method to synthesize acrylate emulsion: concrete steps are (1) dissolving of emulsion, under normal temperature in reactor, nonylphenol polyoxyethylene ether, sodium dodecylbenzenesulfonate are dissolved in deionized water, Stir continuously to form an emulsifier solution; (2) Add butyl acrylate, butyl methacrylate, and methacrylic acid monomers to the emulsifier solution, stir quickly and evenly, then start to reduce the stirring speed, and gradually heat up to 80°C, After the solution reacts with blue light, add ammonium persulfate aqueous solution dropwise. After the ammonium persulfate aqueous solution is added dropwise, the temperature rises to 85°C, and the reaction ends after 2 hours of heat preservation; (3) cool the reaction product to 30°C, add ammonia water to adjust When the pH value reaches neutral, the acrylic emulsion can be obtained by discharging.

[0030] The natural rubber emulsion uses sodium pentachlorophenate low-ammonia latex ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com