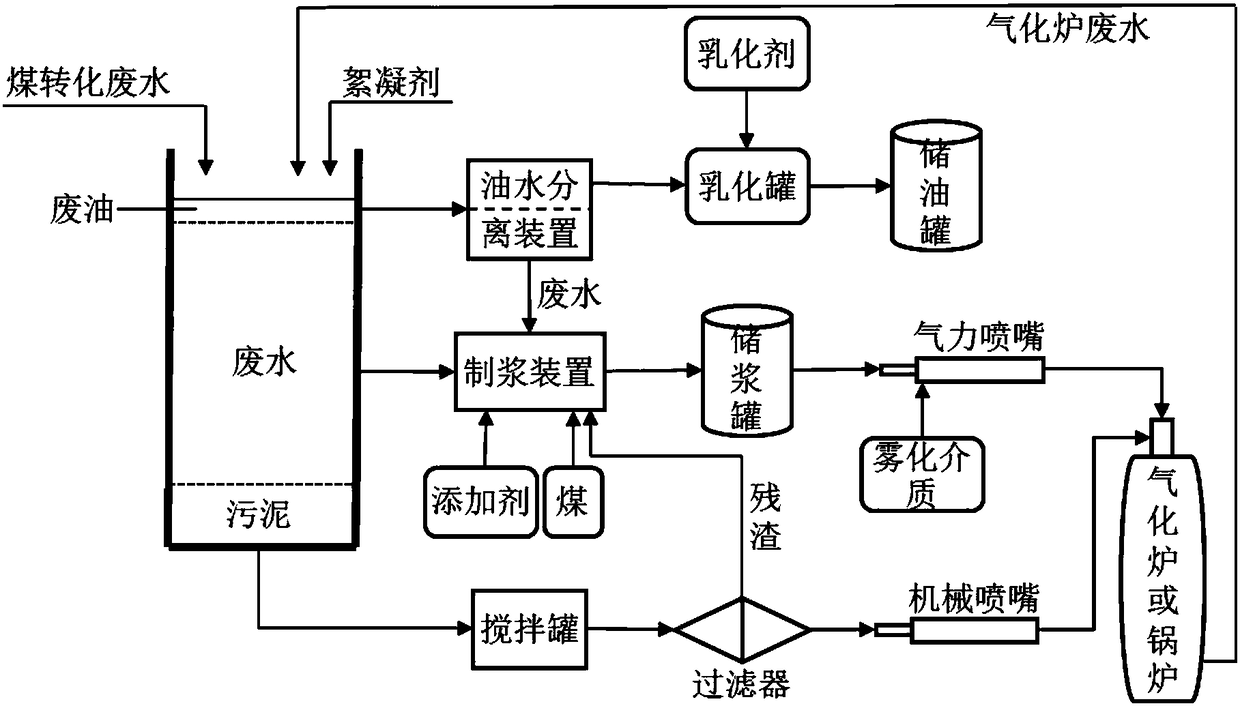

Method for preparing slurry fuel by cascade utilization of coal conversion wastewater

A waste water and fuel technology, applied in the direction of liquid carbon-containing fuel, fuel, petroleum industry, etc., can solve the problems of complex composition of coal conversion waste water, difficulty in unified treatment and recovery methods, etc., achieve obvious social and economic benefits, and avoid adverse effects , the effect of promoting gasification and combustion reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

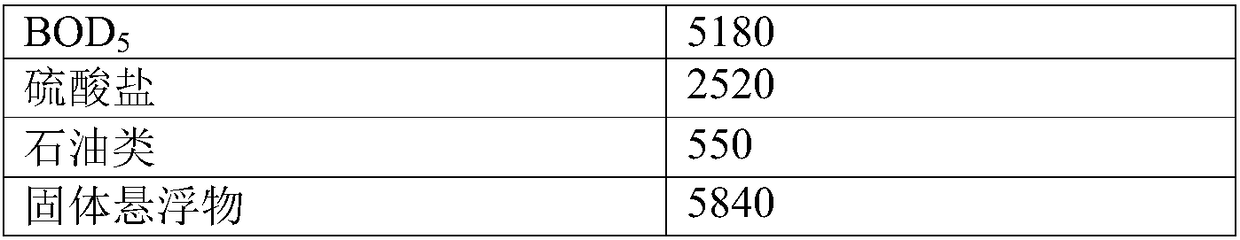

[0037] The water quality analysis of the coal conversion wastewater treated in this embodiment is shown in the following table:

[0038]

[0039]

[0040] The specific implementation steps are as follows:

[0041] (1) In the sedimentation device, add ferrous sulfate and polyacrylamide to the coal conversion wastewater, the addition amount is 1.8g / L and 1.3mg / L respectively, let it stand for 1h, waste tar, water and sludge are separated into three phases layer.

[0042] (2) Separating out the upper strata waste oil of waste water after step (1) treatment, obtain the tar containing moisture 15% after the separation of oil-water separator again, add in the emulsification tank and be the polyvinyl alcohol of 0.8% with the mass ratio of tar, Prepare energy-saving and environment-friendly high-quality emulsified oil with a viscosity of 1180mPa.s, meeting the requirements of industrial applications, and store it in an oil storage tank for standby. The waste water separated by...

Embodiment 2

[0046] The water quality analysis of the coal conversion wastewater treated in this embodiment is shown in the following table:

[0047] Main components in coal conversion wastewater

Content (mg / L)

12

COD cr

210

382

BOD 5

105

315

Petro

11

45

[0048] The specific implementation steps are as follows:

[0049] (1) In the sedimentation device, add ferrous sulfate and polyacrylamide to the coal conversion wastewater, the addition amount is 1.2g / L and 0.7mg / L respectively, let it stand for 1h, waste tar, water and sludge are separated into three phases layer.

[0050] (2) Separating the waste oil in the upper strata of the waste water after step (1) treatment, and then obtaining tar with a moisture content of 5% after being separated by an oil-water separator, adding polyvinyl alcohol with a tar mass ratio of 0.4% in an emulsification tank, ...

Embodiment 3

[0055] The water quality analysis of the coal conversion wastewater treated in this embodiment is shown in the following table:

[0056] Main components in coal conversion wastewater

Content (mg / L)

1220

COD cr

12230

4210

BOD 5

2560

1130

Petro

245

2210

[0057] The specific implementation steps are as follows:

[0058] (1) In the sedimentation device, add ferrous sulfate and polyacrylamide to the coal conversion wastewater, the addition amount is 1.5g / L and 1mg / L respectively, let stand for 1h, waste tar, water, sludge three-phase separation .

[0059] (2) Separating the waste oil in the upper strata of the waste water after step (1) treatment, and then obtaining tar with a moisture content of 10% after being separated by an oil-water separator, adding polyvinyl alcohol with a tar mass ratio of 0.6% in an emulsification tank, Prepare ene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com