Environment-friendly optical glass cleaning agent and preparation method thereof

An optical glass and cleaning agent technology, applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve problems such as poor biodegradation performance, high alkali content, pollution, etc. The effect of fouling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

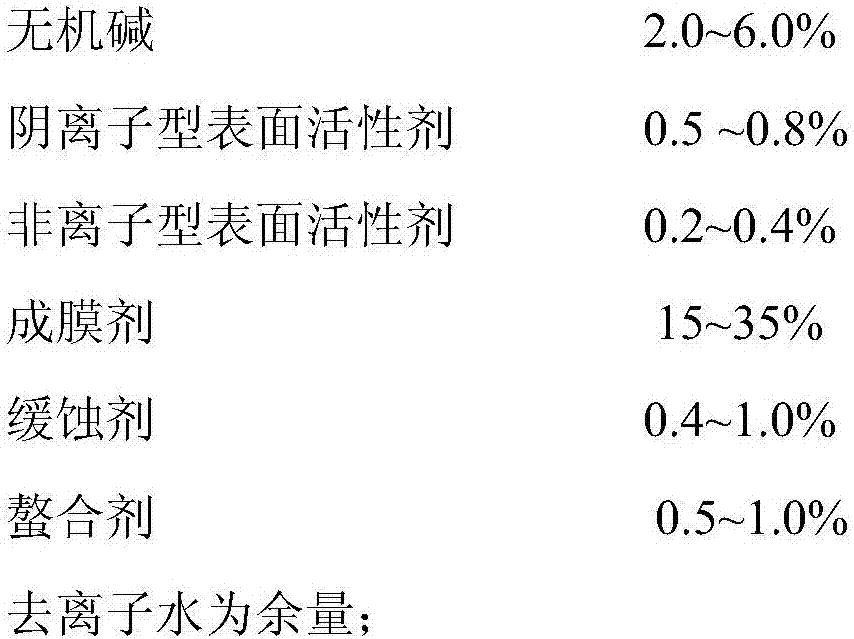

Method used

Image

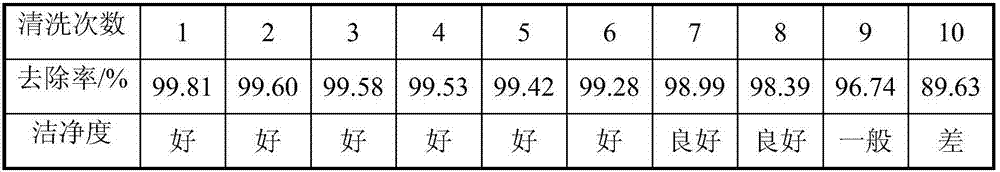

Examples

Embodiment 1

[0032] Raw materials (mass percentage) consist of: sodium hydroxide 2%, sodium lauryl sulfate 0.5%, sodium fatty acid methyl ester sulfonate 0.3%, lauryl glucoside 0.3%, film-forming agent (mass ratio is 1: 1 ethanol and ethylene glycol mixture) 35%, corrosion inhibitor (sodium citrate and triethanolamine mixture with a mass ratio of 1:1) 0.4%, chelating agent (disodium edetate) 0.5%, the balance for deionized water.

[0033]The preparation method is: take an appropriate amount of deionized water, dissolve it into sodium hydroxide, and keep stirring until it is completely dissolved, put it in a constant temperature water tank, and control the temperature at about 40°C, then add anionic surfactant, nonionic surface active agent and Active agent, film forming agent, corrosion inhibitor, chelating agent, every time a raw material is added, it needs to be fully stirred. Finally, keep stirring until the solution is clear and transparent, and the preparation is completed.

[0034]...

Embodiment 2

[0036] The preparation method is the same as in Example 1, and the raw materials (mass percentage) consist of: 4% sodium hydroxide, 0.3% sodium lauryl sulfate, 0.2% sodium fatty acid methyl ester sulfonate, 0.4% lauryl glucoside, film-forming agent (a mixture of ethanol and ethylene glycol in a mass ratio of 1:1) 25%, a corrosion inhibitor (a mixture of sodium citrate and triethanolamine in a mass ratio of 1:1) 0.7%, a chelating agent (ethylenediaminetetraacetic acid di sodium salt) 0.8%, and the balance is deionized water.

[0037] Use this cleaning agent formula to clean the glass dirt with strong adhesion and aging and solidification, and the removal rate is 99.67%. After cleaning, the glass surface has high cleanliness, good transparency, no water streaks, and no pollution when wiped with filter paper.

Embodiment 3

[0039] The preparation method is the same as in Example 1, and the raw materials (mass percentage) consist of: 6% sodium hydroxide, 0.3% sodium lauryl sulfate, 0.3% sodium fatty acid methyl ester sulfonate, 0.2% lauryl glucoside, film-forming agent (a mixture of ethanol and ethylene glycol at a mass ratio of 1:1) 15%, a corrosion inhibitor (a mixture of sodium citrate and triethanolamine at a mass ratio of 1:1) 1.0%, a chelating agent (ethylenediaminetetraacetic acid di sodium salt) 1.0%, and the balance is deionized water.

[0040] Use this cleaning agent formula to clean the glass dirt with strong adhesion and aging and solidification, and the removal rate is 99.69%. After cleaning, the glass surface has high cleanliness, good transparency, no water streaks, and no pollution when wiped with filter paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com