Phase change material for gate driving device, gate driving device and preparation method thereof

A gate-driven, phase-change material technology, applied in the field of microelectronics, can solve the problems of low phase-change critical voltage and low current density, and achieve the effects of increasing phase-change critical voltage, integration and storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The invention provides a phase change material used for a gate drive device, the general formula of the phase change material used for a gate drive device is: Y 1-x As x , wherein, Y is a phase change material including at least one element of the sixth main group, 0

[0024] As an example, the value of x may be selected as 0.05, 0.1, 0.15, 0.2, 0.25 or 0.3 according to actual needs. Preferably, in this embodiment, 0.1≤x≤0.2.

[0025] As an example, the general formula for Y is: A 1-y B y C z , wherein, A is selected from at least one element of the sixth main group, B is selected from at least one element of the fourth main group, and C is N (nitrogen) or P (phosphorus), wherein, 0≤y≤0.5, 0≤z ≤1.

[0026] As an example, the value of y may be 0.1, 0.2, 0.3, 0.4 or 0.5, and the value of z may be 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9 or 1.

[0027] In an example, A may be Se (selenium) or Te (tellurium).

[0028] In another example, A can be Se and Te....

Embodiment 2

[0034] The present invention also provides a method for preparing a phase change material for a gate drive device, the preparation method is suitable for preparing the phase change material for a gate drive device described in Example 1, specifically, using ion Implantation, sputtering, evaporation, chemical vapor deposition, plasma enhanced chemical vapor deposition, low pressure chemical vapor deposition, metal compound vapor deposition, molecular beam epitaxy, atomic vapor deposition or atomic layer deposition At least one method for preparing the phase change material for the gate driving device as described in the first embodiment.

[0035] As an example, taking the magnetron sputtering method to prepare the phase change material for the gate drive device as an example, GeTe alloy target, Si target and As target can be co-sputtered to obtain a material comprising Ge, Te, Si and As Phase change materials; GeTeSi alloy targets, Si targets and As targets can be used for co-s...

Embodiment 3

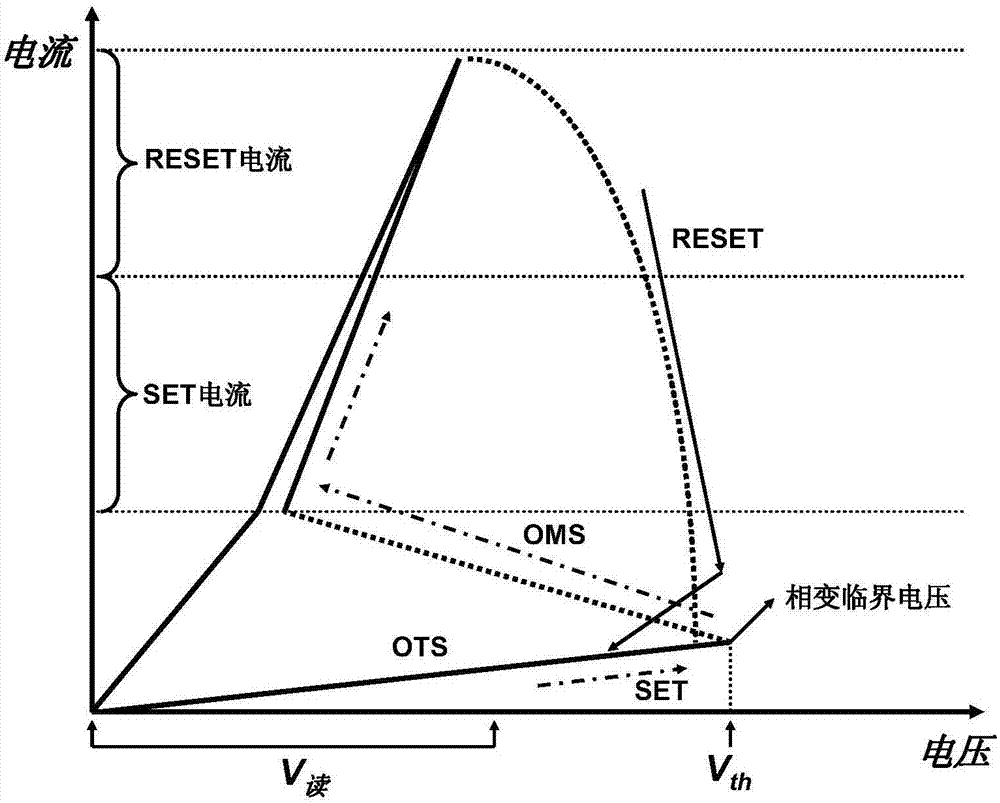

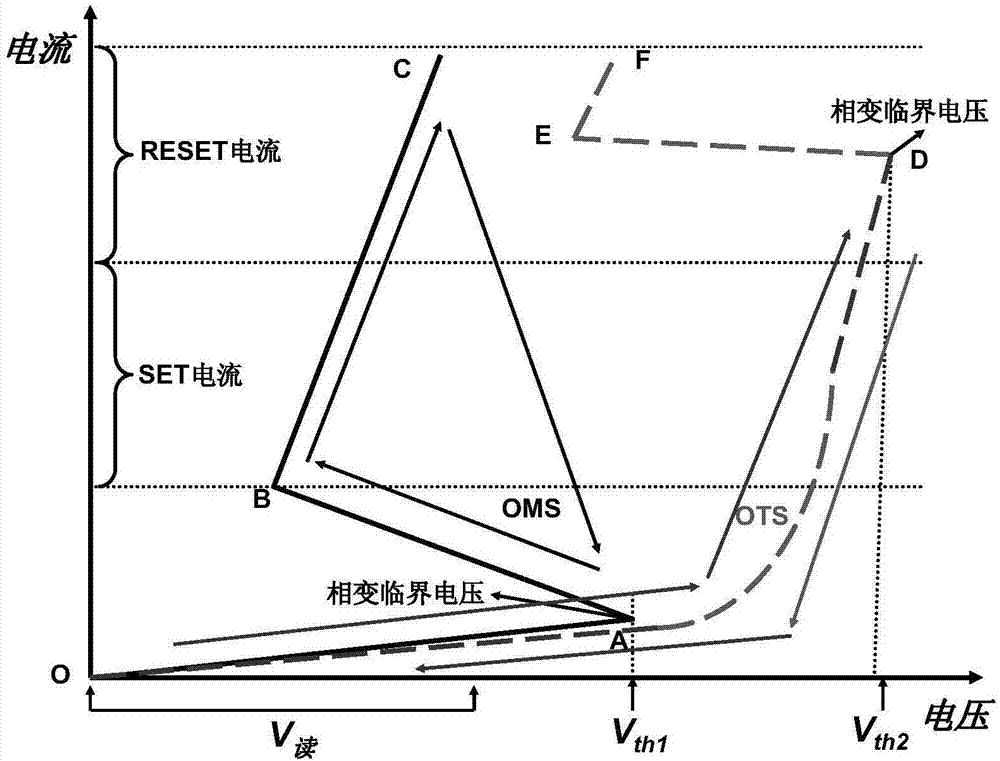

[0037] The present invention also provides a gate driving device, which includes the phase change material as described in the first embodiment. The gate drive device is turned on and off by using the OTS switching characteristics of the phase change material as described in Embodiment 1. At the same time, when the gate drive device is in the on state, the conductive channel formed by arsenic atom doping can provide a large driving force. The current is used to drive the phase change of the phase change memory unit to realize the storage and erasing of information; the gate drive device using the phase change material can realize three-dimensional integration, thereby greatly improving the integration degree and storage density of the memory.

[0038] In summary, the present invention provides a phase change material for a gate drive device, a gate drive device and a preparation method thereof. The general formula of the phase change material for a gate drive device is: Y 1-x ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com