Preparation method of narrow-band-gap-distribution high-purity semi-conductivity single-walled carbon nanotube

A single-walled carbon nanotube, semiconducting technology, applied in the field of controllable preparation of semiconducting single-walled carbon nanotubes, can solve problems such as easy agglomeration, wide diameter distribution, and uncertain nucleation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1. Preparation of partially carbon-coated cobalt nanoparticles and its catalytic growth of narrow bandgap distribution, high-purity semiconducting single-walled carbon nanotubes

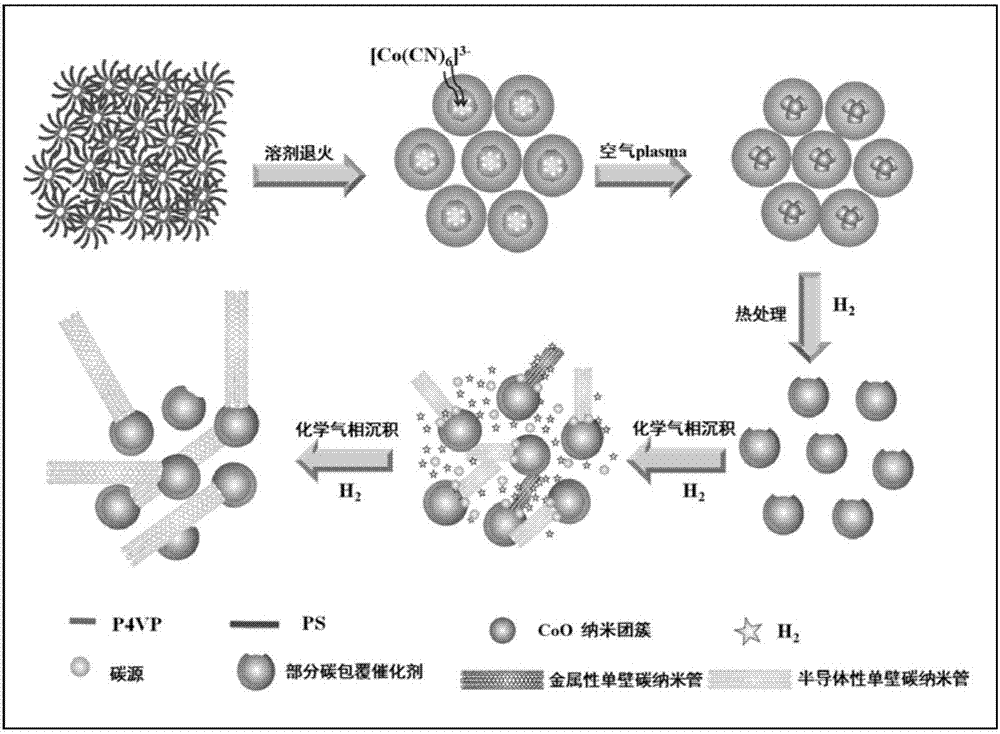

[0046] The specific preparation and growth process are as follows: figure 1 shown.

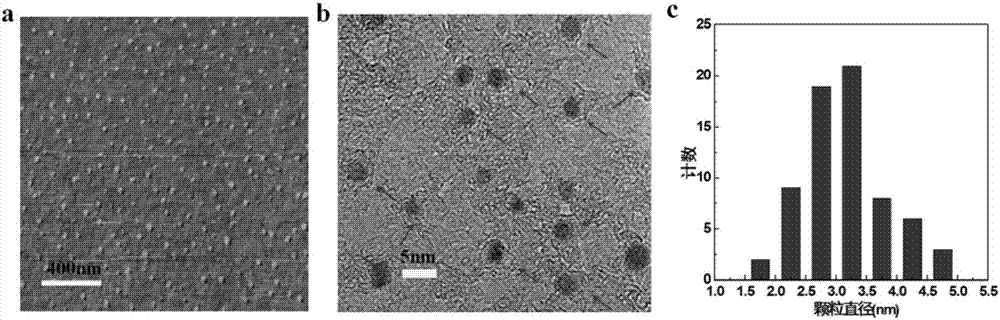

[0047] (1) Preparation of partially carbon-coated Co metal nanoparticles

[0048] The toluene and tetrahydrofuran solution (mass ratio of toluene and tetrahydrofuran 2:1) containing 0.3wt% block copolymer was spin-coated on the surface of the silicon wafer after hydrophilic treatment with 4000rpm, and then placed in toluene and tetrahydrofuran solution (volume ratio 1 :3) Solvent annealing in the vapor of 20 hours, then this silicon chip is placed in 1mM K 3 [Co(CN) 6 ] solution for 3 minutes to adsorb [Co(CN) 6 ] 3- The anions were taken out and washed with deionized water, dried at 60°C for 30 minutes, and finally placed in air plsama (power 20W) for 20 minutes. Place the silicon wafers treated...

Embodiment 2

[0053] Example 2. Preparation of partially carbon-coated iron nanoparticles and its catalytic growth of narrow bandgap distribution, high-purity semiconducting single-walled carbon nanotubes

[0054] (1) Preparation of partially carbon-coated iron metal nanoparticles

[0055] Catalyst preparation step is consistent with embodiment 1, difference is that catalyst precursor is 1mM K 3 [Fe(CN) 6 ] solution. Atomic force microscopy characterization showed that the nanoparticles were uniformly dispersed on the surface of the silicon substrate. The transmission electron microscope observation shows that the surface of all the nanoparticles is partially covered by the carbon layer, and the particle size is uniform. The diameters of 125 particles randomly counted are distributed in the range of 2.5 to 4.0 nm.

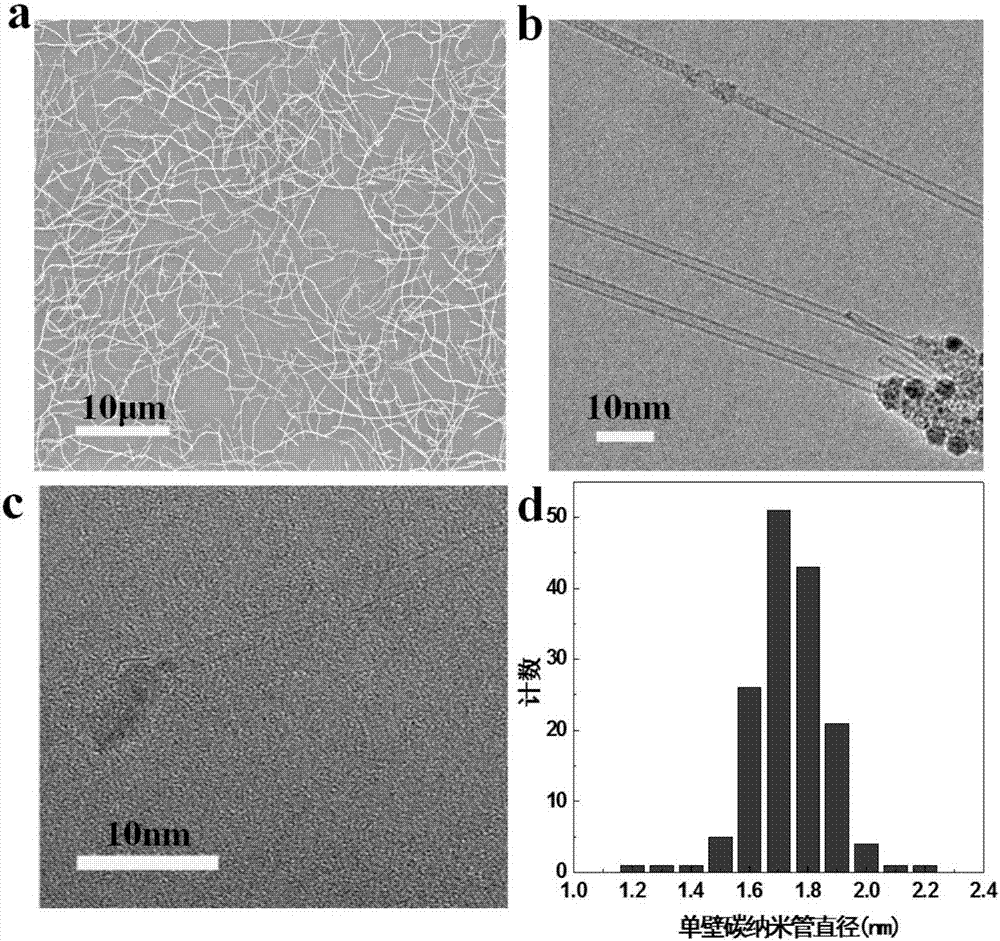

[0056] (2) Growth and characterization of narrow bandgap distribution, high-purity semiconducting single-walled carbon nanotubes

[0057] The growth and characterization of...

Embodiment 3

[0060] Example 3. Preparation of partially carbon-coated iron-tungsten nanoparticles and its catalytic growth of narrow bandgap distribution, high-purity semiconducting single-walled carbon nanotubes

[0061] (1) Preparation of partially carbon-coated iron-tungsten metal nanoparticles

[0062] Catalyst preparation step is consistent with embodiment 1, and difference is that catalyst precursor is 0.5mM K 3 [Fe(CN) 6 ] and 0.5mM (NH 4 ) 10 W 12 o 41 mixed solution. Atomic force microscopy characterization showed that the nanoparticles were uniformly dispersed on the surface of the silicon substrate. The transmission electron microscope observation shows that the surface of all the nanoparticles is partially covered by the carbon layer, and the particle size is uniform. The diameters of 135 particles randomly counted are distributed in the range of 3.0-4.5nm.

[0063] (2) Growth and characterization of narrow bandgap distribution, high-purity semiconducting single-walled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com