Preparation method of iridium complex/polymethyl methacrylate (PMMA) phosphorescent fiber

A technology of polymethyl methacrylate and iridium complexes is applied in the chemical characteristics of fibers, chemical instruments and methods, single-component polyolefin man-made filaments, etc. Affect the luminescent properties of phosphorescent fibers and other issues, and achieve the effects of high luminous efficiency, good compatibility, and improved quantum efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation of PMMA solution: add 3 g PMMA powder and 40 g dried N,N-dimethylformamide (DMF) to a 50 mL conical flask, fix the conical flask on a magnetic stirrer, and keep it at 200 r / s speed. Solids are difficult to dissolve at room temperature. Use a heating mantle to heat to 45°C for 1 hour, and you can clearly observe that the PMMA powder is gradually dissolving. After stirring at room temperature for 10 hours, PMMA was completely dissolved in the DMF solution to obtain a PMMA solution with a mass fraction of 7%.

Embodiment 2

[0021] Iridium complex concentration of 5% (FPyCr) 2 Preparation of Irpic / PMMA solution: Take 4 g of the above-mentioned PMMA solution with a mass fraction of 7% in a clean glass bottle, and then weigh 14 mg of (FPyCr) 2 Irpic is added to a glass bottle with PMMA solution and formulated as (FPyCr) 2 (FPyCr) with an Irpic concentration (relative to PMMA) of 5% 2 Irpic / PMMA solution, add a stirring bar of appropriate size, and stir at room temperature for 5 hours.

Embodiment 3

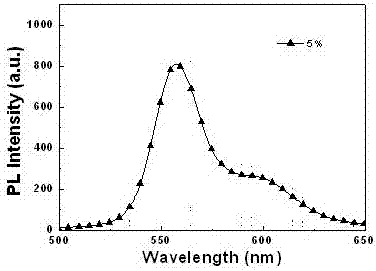

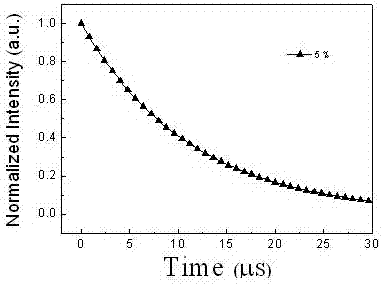

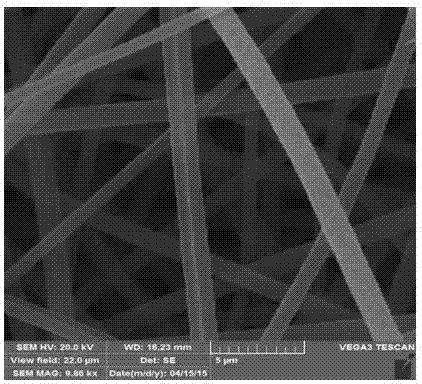

[0023] Preparation of nanofibers: use the laboratory to assemble an electrospinning equipment, take about 3 mL of the prepared solution with a medical syringe, grind the needle tip with a diameter of 0.5 mm with fine sandpaper, and connect it to the positive electrode of the high-voltage power supply. The receiving distance is about 20 cm, the tinfoil receiving plate is connected to the negative pole of the high voltage power supply. Turn on the high voltage power supply and adjust the voltage to 15 kv. The nanofibers were received with a foil cardboard. Wipe the tip of the needle with a clean filter paper every half an hour to prevent the solvent from volatilizing at the tip and causing the solution to solidify, hindering the outflow of the solution and affecting the state of the fiber. After removing the solvent in a vacuum drying oven, the polymethyl methacrylate fiber containing the phosphorescent iridium complex was obtained. figure 1 is the fluorescence emission spectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com