Preparation method of composite conductive agent for water-based power battery

A technology of composite conductive agent and power battery, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the environmental protection problems of ammonia water and other problems, and achieve the effects of environmental friendliness, controllable shape and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

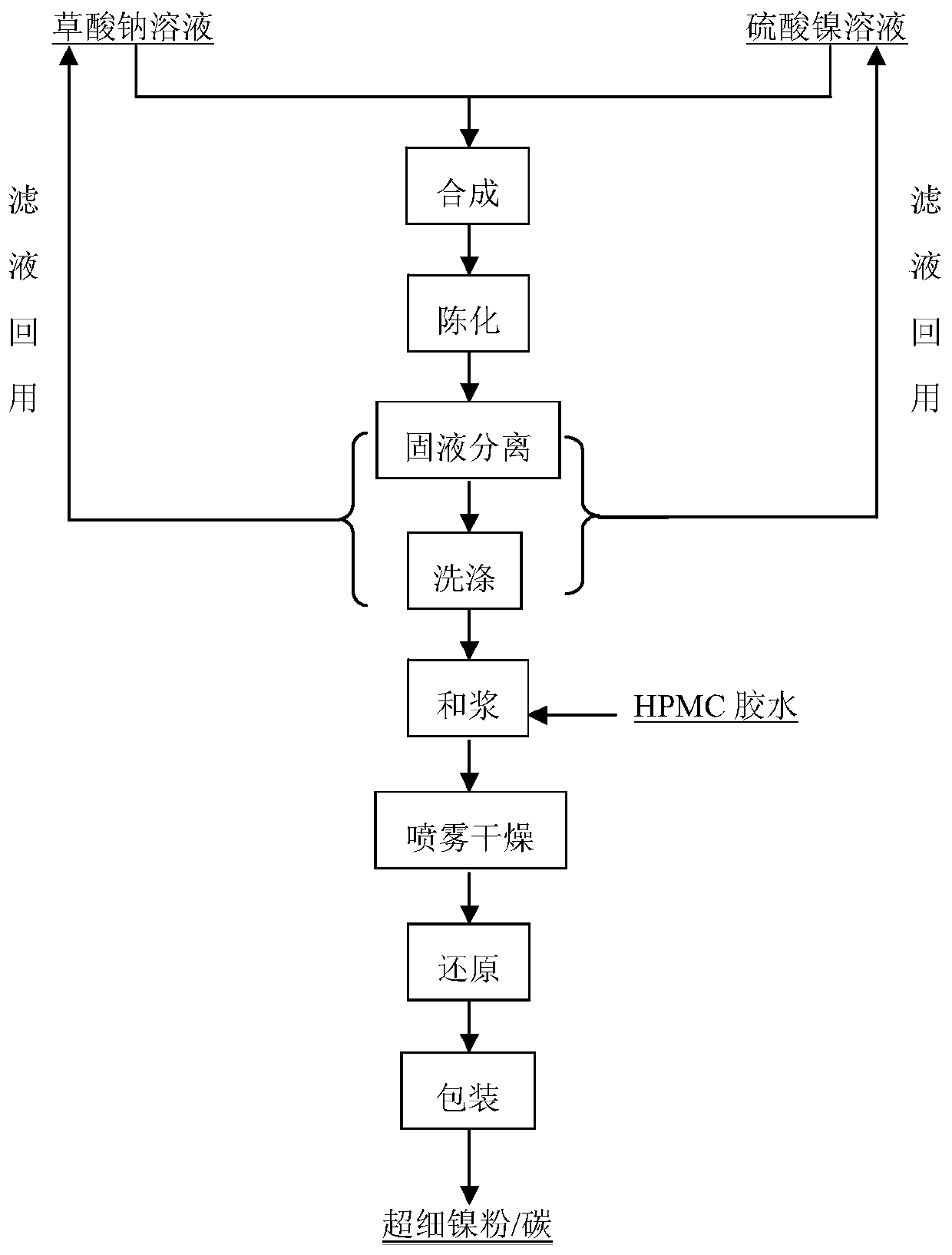

Method used

Image

Examples

Embodiment 1

[0042] (1) Nickel sulfate and sodium oxalate are respectively configured as liquid A and liquid B with deionized water, and the concentration is 2mol / L;

[0043] (2) Use deionized water as the bottom liquid of the reaction kettle, add liquid A and liquid B at the same time, the liquid flow ratio of liquid A and liquid B is 100:100.5, the synthesis temperature is 40°C, the pH value is 10, and the reaction forms amorphous Precipitate nickel oxalate; when the reaction solution reaches the overflow port, open the overflow port valve, the overflow slurry is separated by the cyclone separator, and the slurry that meets the particle size requirements is directly discharged, and the particle size requirements that do not meet the particle size requirements are returned to the reactor to continue the reaction. To achieve the purpose of continuous synthesis.

[0044] (3) After the aging of amorphous precipitated nickel oxalate, the filter cake is obtained by solid-liquid separation, and...

Embodiment 2

[0050] (1) Nickel sulfate and sodium oxalate were configured as liquid A and liquid B respectively with deionized water, and the concentration was 1.5mol / L;

[0051] (2) Use deionized water as the bottom liquid of the reaction kettle, add liquid A and liquid B at the same time, the liquid flow ratio of liquid A and liquid B is 100:100.1, the synthesis temperature is 30°C, the pH value is 6, and the reaction forms amorphous Precipitate nickel oxalate; when the reaction solution reaches the overflow port, open the overflow port valve, the overflow slurry is separated by the cyclone separator, and the slurry that meets the particle size requirements is directly discharged, and the particle size requirements that do not meet the particle size requirements are returned to the reactor to continue the reaction. To achieve the purpose of continuous synthesis.

[0052] (3) After the aging of amorphous precipitated nickel oxalate, the filter cake is obtained by solid-liquid separation, ...

Embodiment 3

[0058] (1) Nickel sulfate and sodium oxalate were configured as liquid A and liquid B respectively with deionized water, and the concentration was 1.8mol / L;

[0059] (2) Use deionized water as the bottom liquid of the reaction kettle, add liquid A and liquid B at the same time, the liquid flow rate ratio of liquid A and liquid B is 100:100.3, the synthesis temperature is 35°C, the pH value is 9, and the reaction forms amorphous Precipitate nickel oxalate; when the reaction solution reaches the overflow port, open the overflow port valve, the overflow slurry is separated by the cyclone separator, and the slurry that meets the particle size requirements is directly discharged, and the particle size requirements that do not meet the particle size requirements are returned to the reactor to continue the reaction. To achieve the purpose of continuous synthesis.

[0060] (3) After the aging of amorphous precipitated nickel oxalate, the filter cake is obtained by solid-liquid separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

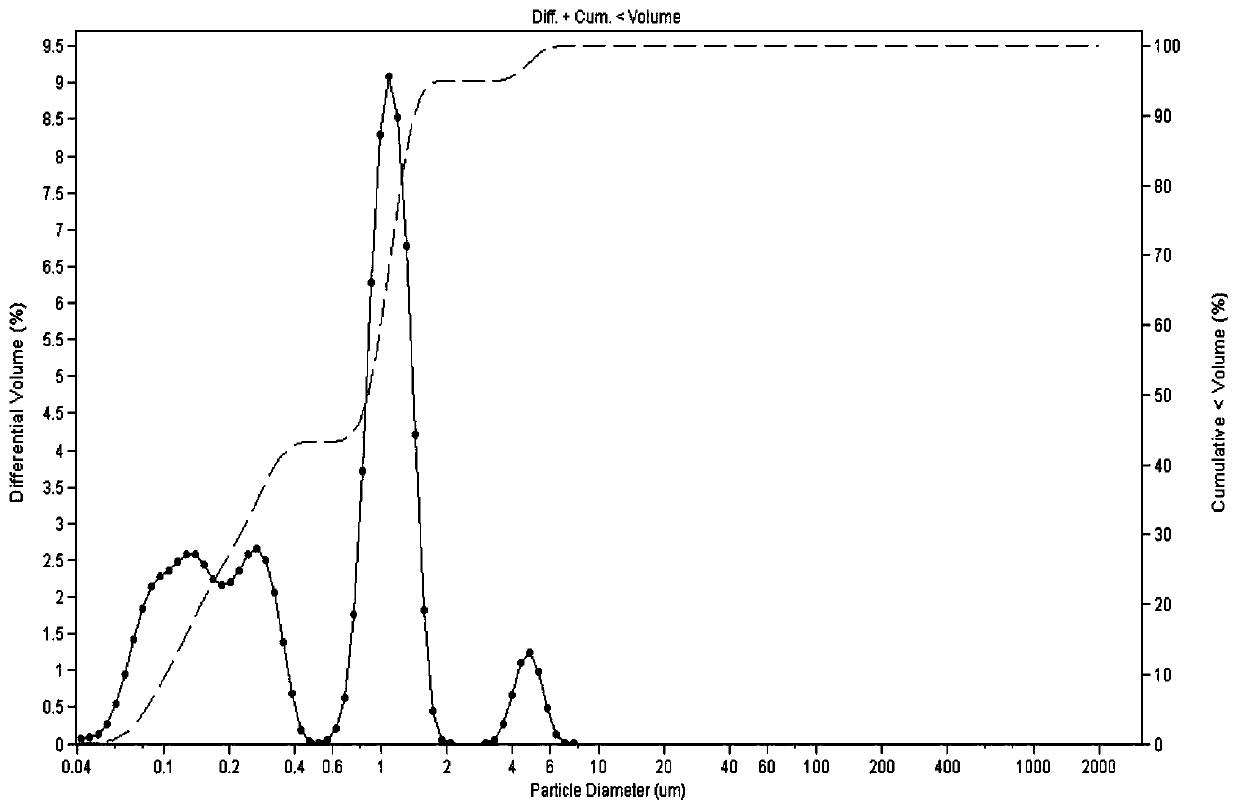

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com