Cobalt-nitrogen co-doped carbon nanotube catalyst, preparing method and application

A carbon nanotube and co-doping technology, applied in the field of electrocatalysis, can solve the problems of high price, scarce platinum reserves, unfavorable large-scale application, etc., and achieve the effect of low cost, stable catalyst performance, and excellent oxygen reduction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

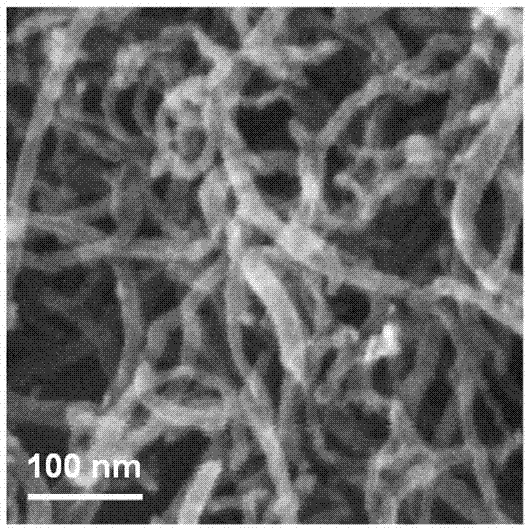

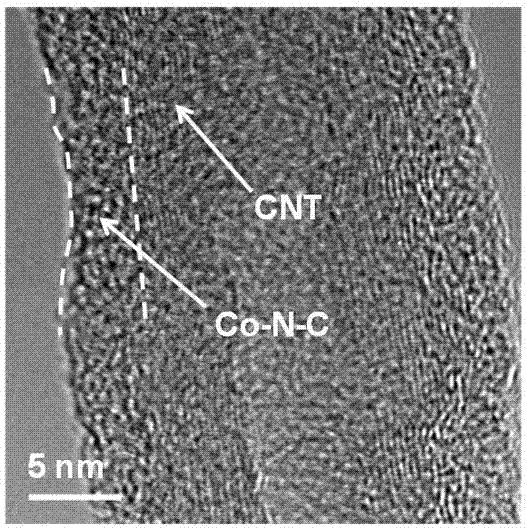

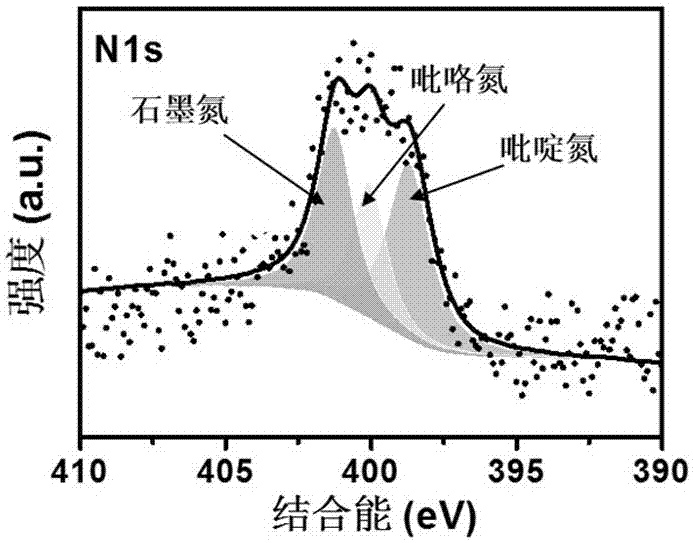

[0032] Preparation of cobalt and nitrogen co-doped carbon nanotube (Co-N / CNT) catalysts:

[0033] The multi-walled carbon nanotubes (CNTs) were oxidized by the modified Hummers method, specifically: the first step, the carbon nanotubes were calcined in a muffle furnace at 500 °C for 1 h, and ultrasonically treated with dilute hydrochloric acid (10%) After half an hour, the iron element in the carbon nanotubes was removed, filtered with suction, and dried. In the second step, take 1 g of carbon nanotubes in a 250 mL round bottom flask, add 23 mL of concentrated sulfuric acid, and stir at room temperature for about 24 h. In the third step, heat the flask oil bath to 40°C and add 200 mg of NaNO 3 , stirred for 5 minutes, and then added 1 g of KMnO in batches 4 , keep the temperature not exceeding 45°C, and stir for 30 minutes to make the KMnO 4 Evenly dispersed in carbon nanotubes, easy to oxidize. Add 3 ml of water every 5 minutes, and keep the temperature not exceeding 45°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com