Tin-silver alloy solder and preparation process thereof

A silver alloy soldering and preparation process technology, applied in the field of tin alloy solder, can solve the problems of short circuit, shortened service life of diodes, easy to damage chip structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

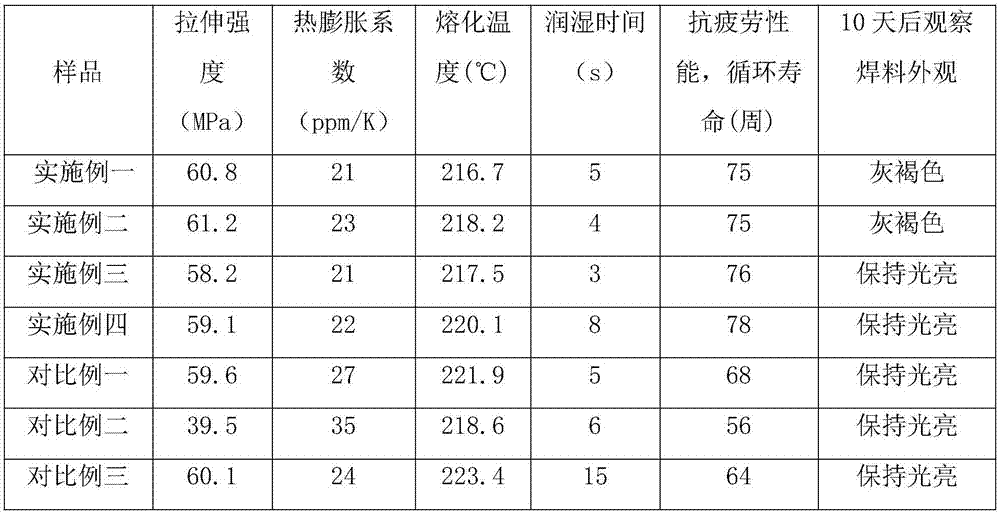

Embodiment 1

[0038]a. Use an angle grinder to polish and grind the surfaces of the silver ingot and the tin ingot respectively to remove the oxides on the surface;

[0039] b. Then weigh 98 parts of tin ingots and 2 parts of silver ingots, first add 25 parts of tin ingots and 2 parts of silver ingots into the vacuum melting furnace, control the temperature between 350°C and 440°C, and the pressure of the air compressor Not less than 0.6MPa, and under the condition of electromagnetic stirring, the tin-silver liquid is mixed evenly, and then the remaining tin ingot is added and mixed evenly.

[0040] c. Using a rapid cooling device to rapidly cool down the molten tin-silver alloy liquid obtained in step b to 120° C. within two minutes to form tin-silver alloy solder.

Embodiment 2

[0042] a. Use an angle grinder to polish and grind the surfaces of the silver ingot and the tin ingot respectively to remove the oxides on the surface;

[0043] b. Then weigh 97.5 parts of tin ingots and 2.5 parts of silver ingots, first add 25 parts of tin ingots and 2.5 parts of silver ingots into the vacuum melting furnace, heat and melt, control the temperature between 350°C and 440°C, and press air The pressure of the machine is not less than 0.6MPa, and the tin-silver liquid is mixed evenly under the condition of electromagnetic stirring, and then the remaining tin ingot is added and mixed evenly;

[0044] c. Using a rapid cooling device to rapidly cool down the molten tin-silver alloy liquid obtained in step b to 120° C. within two minutes to form tin-silver alloy solder.

Embodiment 3

[0046] a. Use an angle grinder to polish and grind the surfaces of the silver ingot and the tin ingot respectively to remove the oxides on the surface;

[0047] b. Then weigh 97.5 parts of tin ingots, 2.44 parts of silver ingots, and 0.06 parts of gadolinium metal, first add 25 parts of tin ingots, 2.44 parts of silver ingots, and 0.06 parts of gadolinium metal into a vacuum melting furnace for heating and melting, and control the temperature at 350 Between ℃ and 440℃, the pressure of the air compressor is not less than 0.6MPa, and the tin-silver liquid is mixed evenly under the condition of electromagnetic stirring, and then the remaining tin ingot is added to mix evenly;

[0048] c. Use a rapid cooling device to rapidly cool down the tin-silver alloy liquid obtained in step b to 120° C. within two minutes to form tin-silver alloy solder.

[0049] d. Preparation of inorganic passivation solution: potassium dichromate, 10g / L; sodium carbonate: 20g / L; mix well, and then soak th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com