Preparation method of high-dispersibility ITO powder

A high-dispersion, powder technology, applied in chemical instruments and methods, inorganic chemistry, gallium/indium/thallium compounds, etc., can solve the problems of low sintering activity, more agglomeration, and unsatisfactory dispersion of ITO powder, and achieve Good fluidity, less hard agglomeration, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

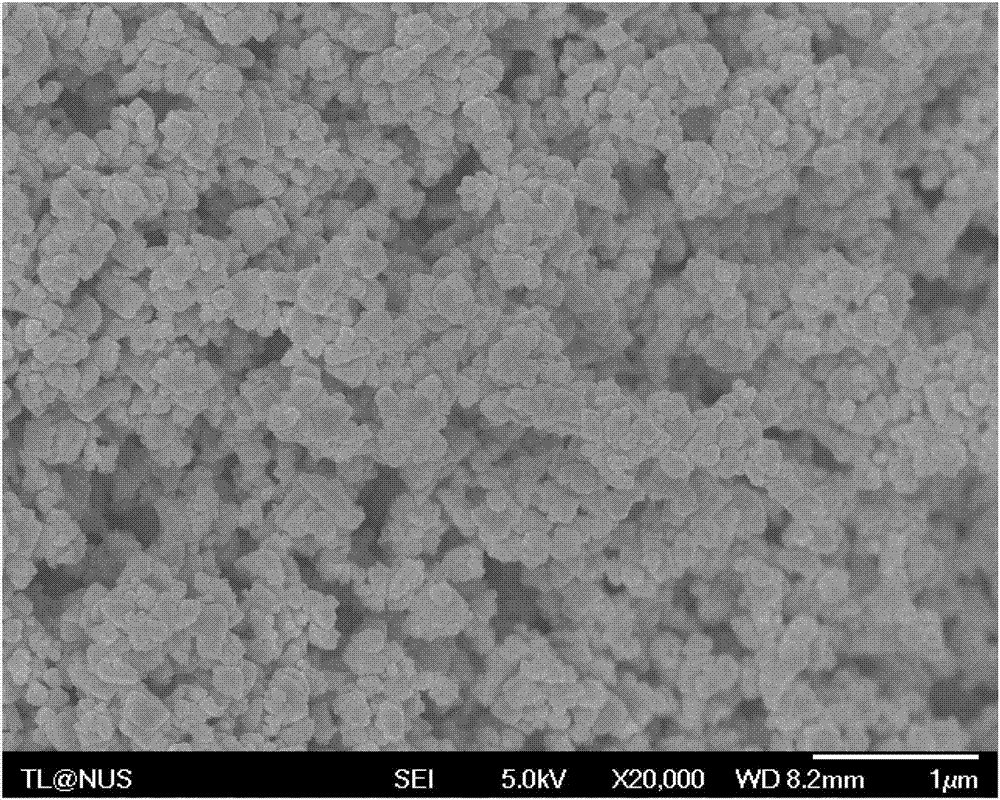

Image

Examples

Embodiment 1

[0024] The present embodiment provides a kind of preparation method of highly dispersible ITO powder, comprises the following steps:

[0025] (1) Weigh metal In and add to HNO 3 Completely dissolved in solution, according to In 2 o 3 / SnO 2 The mass ratio is 9:1, weigh SnCl 4 ·5H 2 O white crystals are added in the indium salt solution, stirred evenly to prepare the mixed salt solution;

[0026] (2) Take NH with a pH value of 7 4 AC buffer solution, adding a composite dispersant to the buffer solution; the amount of the composite dispersant added is 4% of the total amount of ITO powder; the composite dispersant is sodium dodecylsulfonate with a mass ratio of 1:2:1 , pregelatinized starch and polyvinylpyrrolidone;

[0027] (3) Add ammonia water and mixed salt solution dropwise to the buffer solution at the same time, and during the dropping process, adjust the drip rate of ammonia water so that the pH value of the solution remains basically unchanged, and generate an ind...

Embodiment 2

[0033] The present embodiment provides a kind of preparation method of highly dispersible ITO powder, comprises the following steps:

[0034] (1) Weigh metal In and add to HNO 3 Completely dissolved in solution, according to In 2 o 3 / SnO 2 The mass ratio is 9:1, weigh SnCl 4 ·5H 2 O white crystals are added in the indium salt solution, stirred evenly to prepare the mixed salt solution;

[0035] (2) Take NH with a pH value of 6 4 AC buffer solution, adding a composite dispersant to the buffer solution; the amount of the composite dispersant added is 2% of the total amount of ITO powder; the composite dispersant is sodium dodecylsulfonate with a mass ratio of 1:2:1 , pregelatinized starch and polyvinylpyrrolidone;

[0036] (3) Add ammonia water and mixed salt solution dropwise to the buffer solution at the same time, and during the dropping process, adjust the drip rate of ammonia water so that the pH value of the solution remains basically unchanged, and generate an ind...

Embodiment 3

[0042] The present embodiment provides a kind of preparation method of highly dispersible ITO powder, comprises the following steps:

[0043] (1) Weigh metal In and add to HNO 3 Completely dissolved in solution, according to In 2 o 3 / SnO 2 The mass ratio is 9:1, weigh SnCl 4 ·5H 2 O white crystals are added in the indium salt solution, stirred evenly to prepare the mixed salt solution;

[0044] (2) Take NH with a pH value of 7 4 AC buffer solution, adding a composite dispersant to the buffer solution; the amount of the composite dispersant added is 5% of the total amount of ITO powder; the composite dispersant is sodium dodecylsulfonate with a mass ratio of 1:2:1 , pregelatinized starch and polyvinylpyrrolidone;

[0045](3) Add ammonia water and mixed salt solution dropwise to the buffer solution at the same time, and during the dropping process, adjust the drip rate of ammonia water so that the pH value of the solution remains basically unchanged, and generate an indi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com