A kind of foam cement board and preparation method thereof

A foamed cement board and cement technology, applied in the field of cement, can solve the problems of decreased thermal insulation effect, poor foaming effect, fast solidification speed, etc., and achieve the effect of reducing weight, good complexing effect, and improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

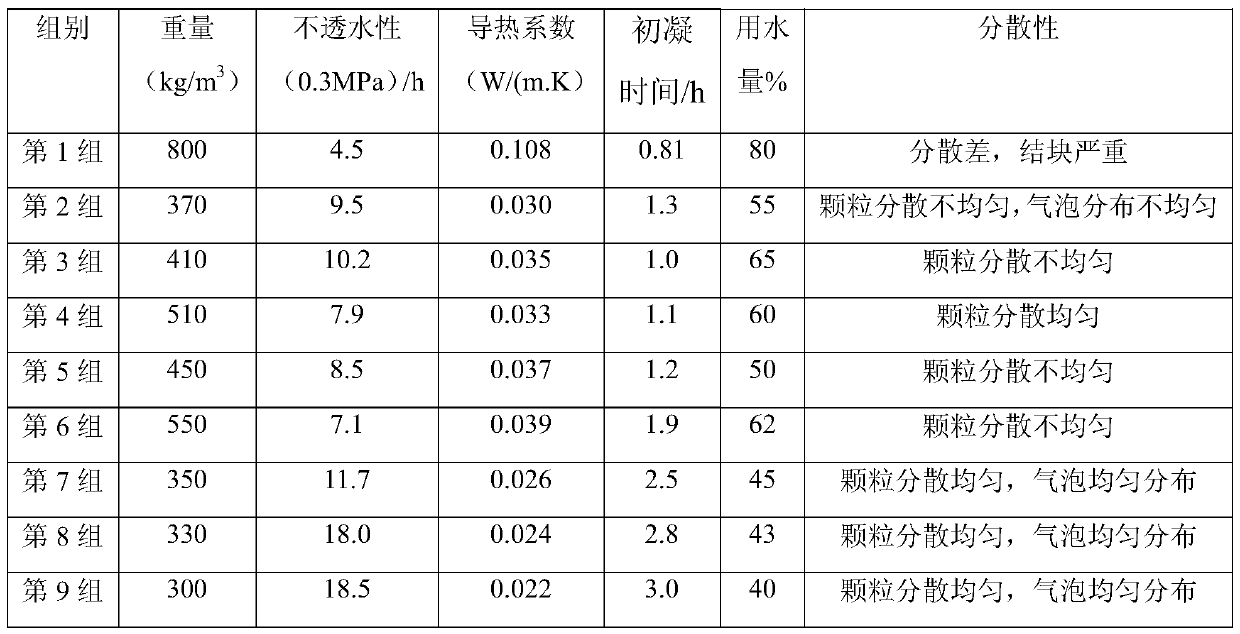

Image

Examples

Embodiment 1

[0024] A foamed cement board, made of the following raw materials in parts by weight: 60 parts of cement, 10 parts of tetrasodium iminodisuccinate, 10 parts of dipotassium ethylenediaminetetraacetic acid, 10 parts of potassium chromate, tetrahydroisomazone 5 parts, 5 parts of 4,4-diyellow hydrazide diphenyl ether, 5 parts of 4,4'-p-sulfonyl hydrazide diphenyl ether, 2 parts of fatty alcohol sodium sulfate, 2 parts of heavy alkylbenzene sulfonate, polymethyl 0.3 part of sodium acrylate, 0.3 part of sodium sulfamate, 0.5 part of 2,3-dihydroxysuccinic acid, 0.5 part of sodium hexametaphosphate and 30 parts of water.

[0025] The prediction of above-mentioned proportioning is used following method to prepare foamed cement board, specifically comprises the following steps:

[0026] (1) Accurately weigh tetrasodium iminodisuccinate, dipotassium ethylenediaminetetraacetate, potassium chromate, sodium fatty alcohol sulfate, sodium heavy alkylbenzene sulfonate, sodium polymethacrylate,...

Embodiment 2

[0034] A foamed cement board, made of the following raw materials in parts by weight: 65 parts of cement, 13 parts of tetrasodium iminodisuccinate, 13 parts of dipotassium ethylenediaminetetraacetic acid, 13 parts of potassium chromate, and tetrahydroisomazone 7 parts, 7 parts of 4,4-diyellow hydrazide diphenyl ether, 7 parts of 4,4'-p-sulfonyl hydrazide diphenyl ether, 3 parts of fatty alcohol sodium sulfate, 3 parts of heavy alkylbenzene sulfonate, polymethyl 0.4 part of sodium acrylate, 0.4 part of sodium sulfamate, 0.6 part of 2,3-dihydroxysuccinic acid, 0.6 part of sodium hexametaphosphate and 35 parts of water.

[0035] The prediction of above-mentioned proportioning is used following method to prepare foamed cement board, specifically comprises the following steps:

[0036] (1) Accurately weigh tetrasodium iminodisuccinate, dipotassium ethylenediaminetetraacetate, potassium chromate, sodium fatty alcohol sulfate, sodium heavy alkylbenzene sulfonate, sodium polymethacryl...

Embodiment 3

[0044]A foamed cement board, made of the following raw materials in parts by weight: 70 parts of cement, 15 parts of tetrasodium iminodisuccinate, 15 parts of dipotassium ethylenediaminetetraacetic acid, 15 parts of potassium chromate, tetrahydroisomazone 10 parts, 10 parts of 4,4-diyellow hydrazide diphenyl ether, 10 parts of 4,4'-p-sulfonyl hydrazide diphenyl ether, 4 parts of fatty alcohol sodium sulfate, 4 parts of heavy alkylbenzene sulfonate, polymethyl 0.5 part of sodium acrylate, 0.5 part of sodium sulfamate, 0.7 part of 2,3-dihydroxysuccinic acid, 0.7 part of sodium hexametaphosphate and 40 parts of water.

[0045] The prediction of above-mentioned proportioning is used following method to prepare foamed cement board, specifically comprises the following steps:

[0046] (1) Accurately weigh tetrasodium iminodisuccinate, dipotassium ethylenediaminetetraacetate, potassium chromate, sodium fatty alcohol sulfate, sodium heavy alkylbenzene sulfonate, sodium polymethacrylat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com