Coating, a preparing method thereof, two-component coating comprising the coating and a component

A two-component, component technology, applied in the field of coatings, can solve the problems of reliability and safety, electronic components or electrical appliances are easy to accumulate dust, shorten the service life of electronic components or electrical appliances, etc., to improve safety and reliability , enhance hydrophobic and dustproof performance, overcome the effect of poor heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In a second aspect, an embodiment of the present invention provides a method for preparing the coating as described above, including:

[0041] Mix the polymer monomer of the film-forming substance, the dispersion liquid of solid microspheres and the reaction solvent, and cause the polymer monomer of the film-forming substance to undergo a bulk polymerization reaction under the action of the initiator to obtain the film-forming substance containing the Substance, the coating of the solid microsphere and the dispersion medium; wherein, the film-forming substance is a polymer with a surface dyne value less than or equal to 36 dyn / cm, the surface friction coefficient of the solid microsphere is less than or equal to 0.1, and the The film-forming substance can coat the solid microspheres on the surface of the film-forming substance during film formation.

[0042] The embodiment of the present invention provides a method for preparing a coating, by mixing the polymer monomer ...

Embodiment 1

[0077] Add 700g ethyl acetate, 37.59g butyl acetate, 2g fatty alcohol polyoxyethylene ether, 5g0.12μm mass fraction of 20% polytetrafluoroethylene dispersion and 51.59g butyl acrylate, 44.22g methacrylic acid in the reactor Methyl ester, 22.11g of hydroxyethyl methacrylate, 29.48g of dodecafluoroheptyl methacrylate, stir evenly and then raise the temperature to 90°C, dropwise add about 0.59g of azobisisobutyronitrile and 58.41g of acetic acid within 3h The initiator solution (mass fraction: 1%) configured with ethyl ester was kept at the temperature for 1 h after the dropwise addition was completed, and then cooled to normal temperature to obtain the A coating.

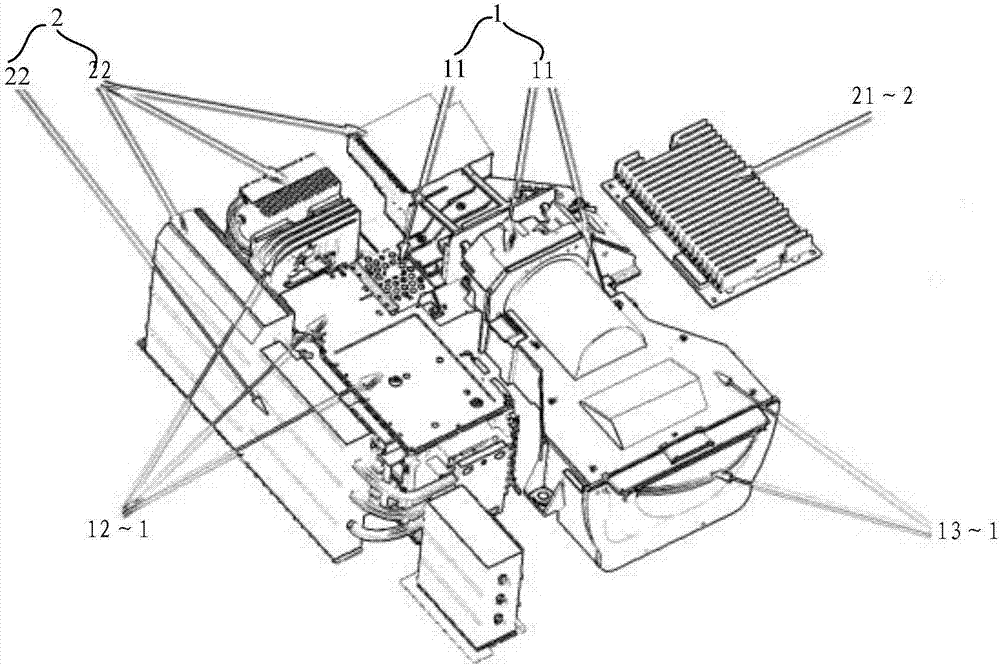

[0078] After mixing the coating A and the curing agent B containing NCO groups according to the molar ratio of -NCO / -OH=1, spray the coating on the surface of the laser radiator material, bake at 60°C for 30 minutes, and form a Coating with a thickness of 15 μm.

[0079] The dyne value of the surface of the sprayed F...

Embodiment 2

[0081] Add 983.99g ethyl acetate, 1g fatty alcohol polyoxyethylene ether, 2g0.4μm mass fraction to 50% polytetrafluoroethylene dispersion and 39.55g butyl acrylate, 63.28g methyl methacrylate, 15.82g Hydroxyethyl methacrylate, 19.5g hexafluorobutyl methacrylate, 20.06g trifluoroethyl methacrylate, stir evenly, heat up to 91°C, dropwise add about 0.2g azobisisobutyronitrile within 3 hours , 0.59g benzoyl peroxide and 15.01g ethyl acetate are configured with the initiator solution (mass fraction is 5%), continue to keep temperature 2 hours after dropwise addition is completed, be cooled to normal temperature, obtain A coating.

[0082] After mixing the coating A and the curing agent B containing NCO groups according to the molar ratio of -NCO / -OH=1.03, spray the coating on the surface of the laser projector housing, and dry it at 65°C for 25 minutes. A coating with a thickness of 15 μm is formed on the surface.

[0083] The surface dyne value after testing spraying was 32dyn / cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

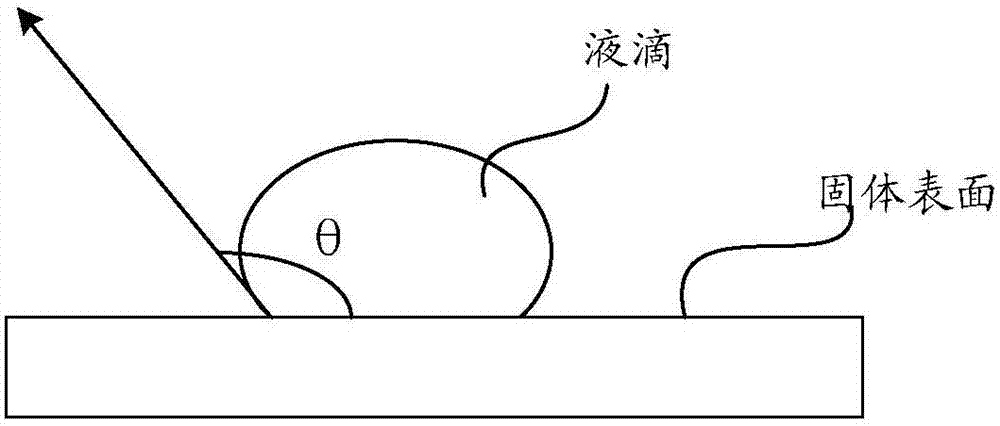

| Contact angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com