Method for preparing silica/carbon nanometer material with micropores and ordered mesopores

A carbon nanomaterial and silicon oxide technology, which is applied in the field of preparation of silicon oxide/carbon nanomaterials, can solve the problems of carbon residue, complex synthesis process, difficult functionalization of carbon nanomaterials, etc., and achieves easy operation, simplified preparation process, Effects with low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a silicon oxide / carbon nanomaterial with micropores and ordered mesopores, comprising the following steps:

[0032] Step 1. Add 2-3g template agent (such as alkyltrimethylammonium bromide) (analytical pure) into the flask, then add 54-104mL water and 0-50mL absolute ethanol (analytical pure liquid ethanol, mass fraction 99.7% or more), magnetically stirred until hexadecyltrimethylammonium bromide is completely dissolved to clarification (dissolution is enough, it can be dissolved by heating in a water bath at 40-60°C, and the stirring speed is not limited), and moved to Stir magnetically at room temperature (25°C) (stirring speed is slow, generally 100-300r / min), then add 0.984-3.28g resorcinol (analytical pure), 372-1240μL formaldehyde (mass fraction 37-40 %), then add 4-10mL silane coupling agent dropwise (the stirring speed is accelerated when the silane coupling agent is added dropwise, generally 800r / min), the concentra...

Embodiment 1

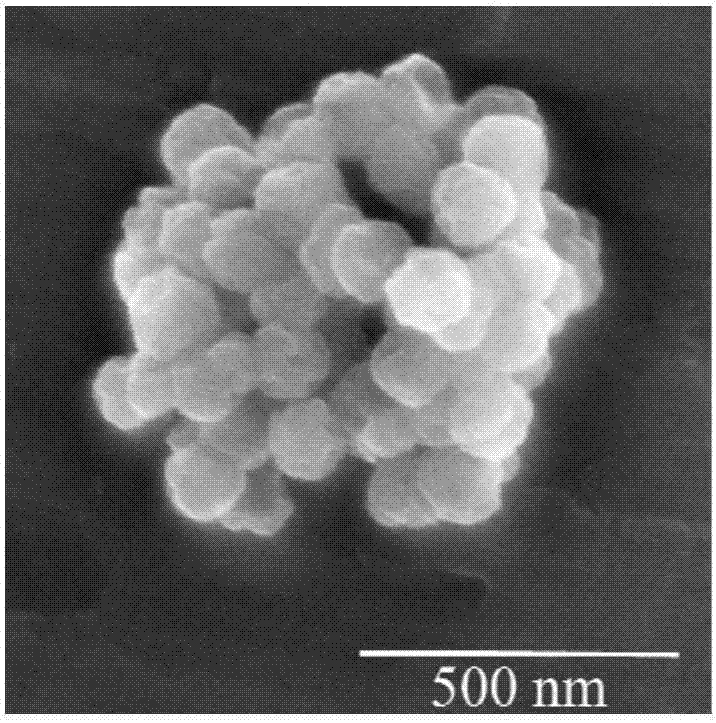

[0043] This embodiment provides a method for preparing a silicon oxide / carbon nanomaterial with micropores and ordered mesopores, comprising the following steps:

[0044] Step 1. Add 2.6120g of cetyltrimethylammonium bromide to the flask, then add 96mL of water and 8mL of absolute ethanol, stir magnetically in a water bath until the cetyltrimethylammonium bromide is dissolved until it becomes clear, and then move to Magnetic stirring at room temperature (stirring speed is slower), then add 2.296g resorcinol (analytical pure), 868 μ L formaldehyde (mass fraction is 37%), then add 6mL orthosilicate ethyl ester dropwise (stirring speed is faster ), SiO in tetraethyl orthosilicate 2 The mass fraction of the mixture satisfies 28%, and the stirring is continued for 5 minutes, 1200 μL of ammonia water (25% mass fraction) is added dropwise, and stirred at room temperature for 24 hours to obtain a gel;

[0045] Step 2. Put the gel obtained in step 1 into a reaction kettle, react in an...

Embodiment 2

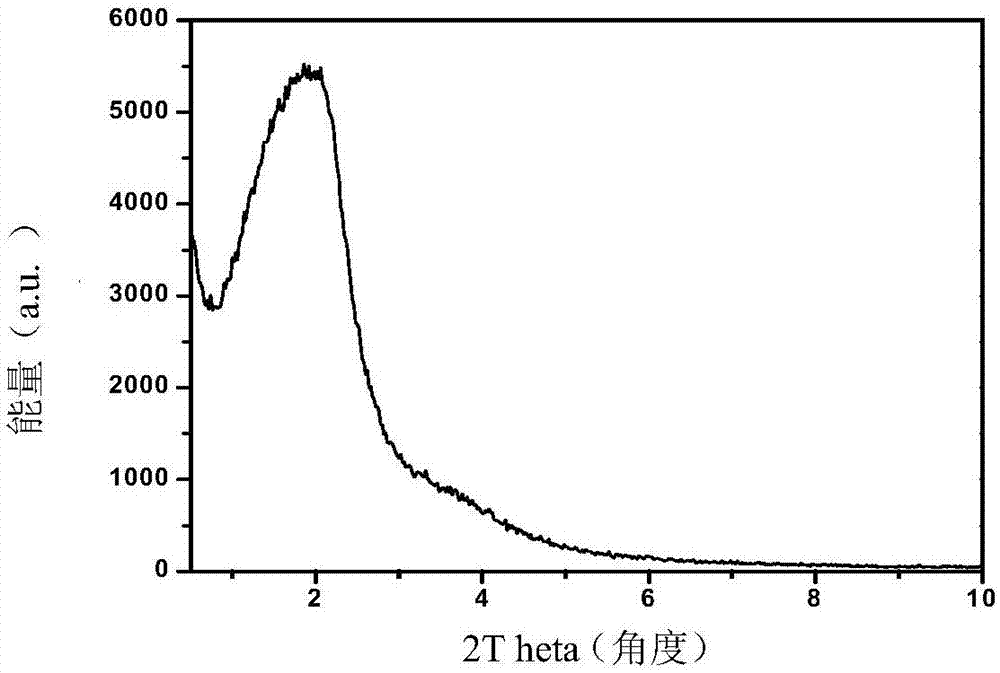

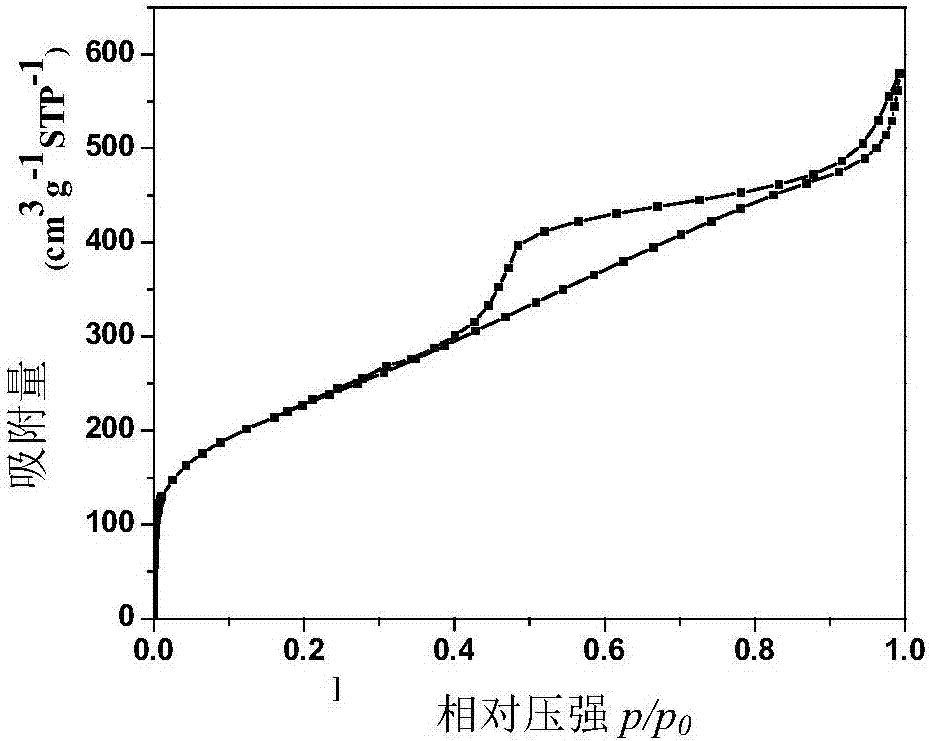

[0050] Adopting the experimental process of Example 1, the difference is that the addition of absolute ethanol is 30mL, and the addition of water is 74mL; the mesopore diameter of the obtained silicon oxide / carbon nanomaterial is 2.8nm, and the specific surface area is 884m 2 / g, the micropore diameter is 0.91nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com