Antifouling paint and preparation method thereof

A technology of anti-fouling coatings and anti-fouling additives, applied in the field of coatings, can solve the problems of marine organisms adhesion, etc., achieve the effects of long release period, simple and practical preparation method, and good anti-fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

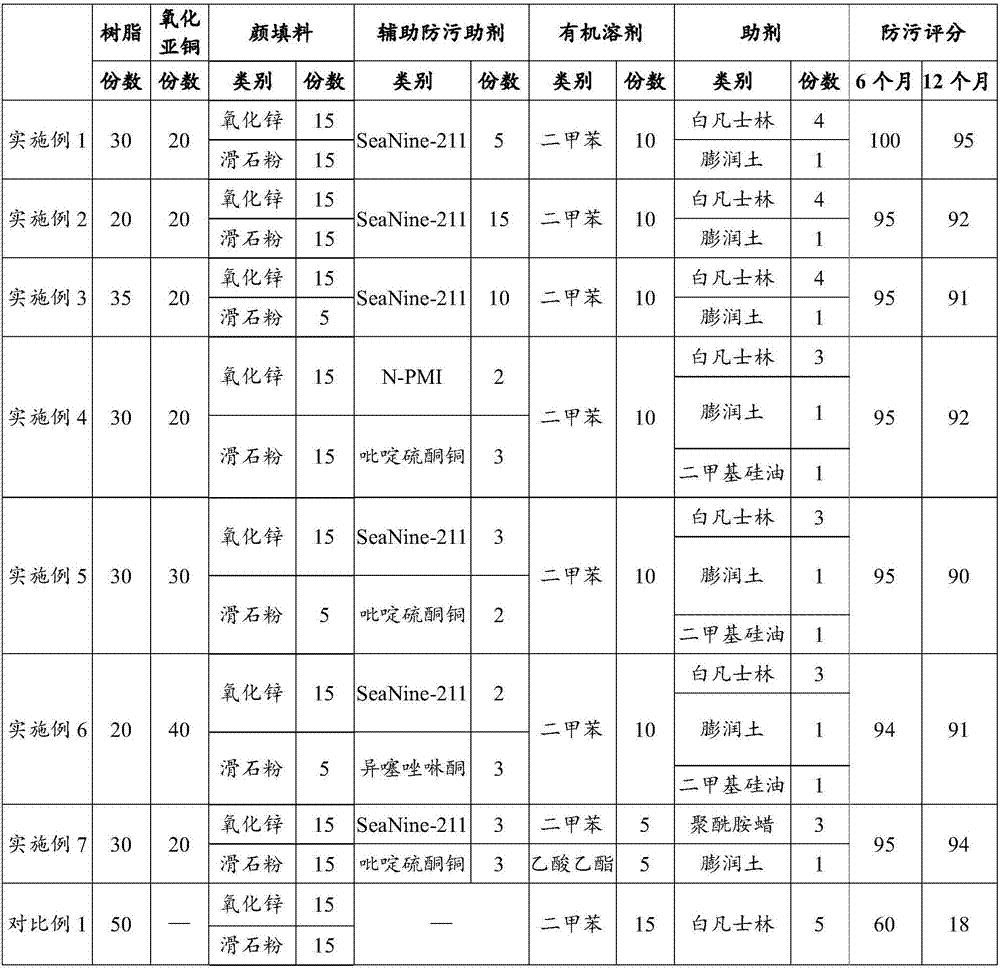

Examples

Embodiment 1

[0033] 1) Add 30 parts of degradable polyurethane resin with broken main chain, 20 parts of cuprous oxide and 5 parts of SeaNine-211 antifouling agent into a metal tank with a sealed cover. Shake at / min for 10 minutes, and at the same time pass condensed water through the metal tank to cool down to ensure that the temperature is not higher than 50°C;

[0034] 2) Add 4 parts of white vaseline, 1 part of bentonite, 15 parts of zinc oxide, 15 parts of talcum powder, and 10 parts of xylene into the metal tank in turn, vibrate for 2 hours at a speed of 3000r / min on the paint rapid disperser, and cool down with condensed water , to ensure that the reaction temperature is not higher than 50°C;

[0035] 3) Use a scraper fineness meter to detect the fineness of the paint, and when the fineness of the paint reaches below 50 microns, the required antifouling paint can be obtained.

[0036] The prepared antifouling paint is evenly coated on the surface of the hanging board to form an an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com