Non-rare earth impurity and rare earth element extraction and separation method

A rare earth element and separation method technology, which is applied in the field of extraction and separation of non-rare earth impurities and rare earth elements, can solve the problems that the organic phase and the water phase cannot be separated, the advantages of extraction and separation are not large, and the extraction process is emulsified, so as to achieve comprehensive utilization, The effect of avoiding consumption and eliminating ammonia nitrogen wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

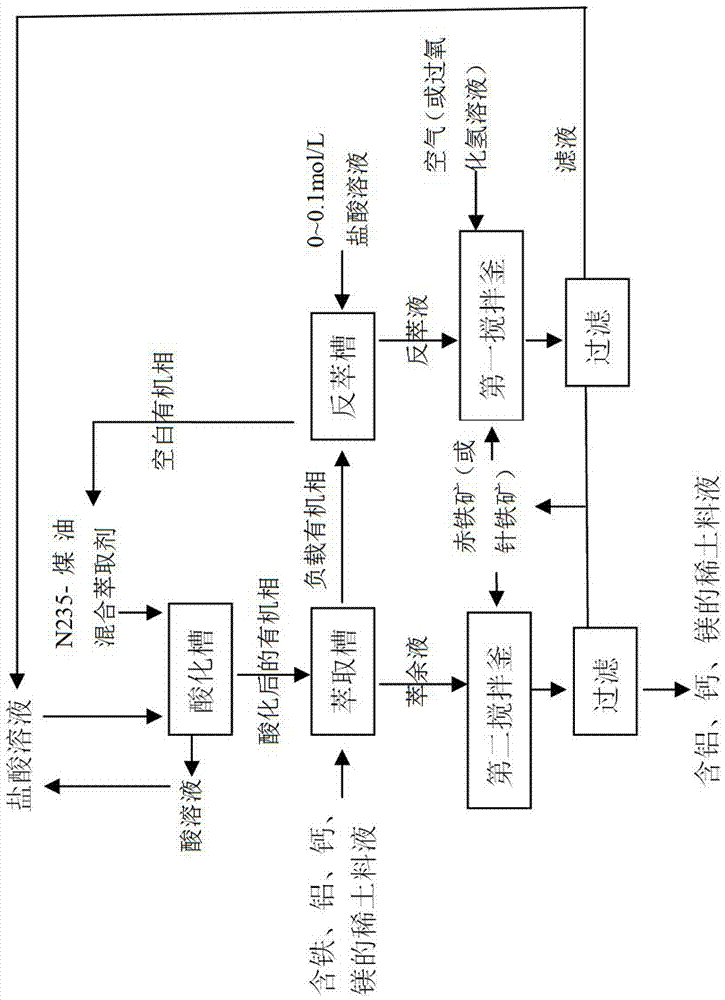

Embodiment 1

[0035] Mix 30% N235 and 70% kerosene evenly and send them into the acidification tank, mix with 1mol / L hydrochloric acid solution for 10 minutes, after the two phases are separated, separate the upper organic phase, send it into the extraction tank, and mix it with iron, aluminum, The rare earth chloride leaching solution of calcium and magnesium (the concentration of rare earth is 1.5mol / L, the concentration of iron is 1.35g / L, the concentration of aluminum is 3g / L, the concentration of calcium is 4g / L, and the concentration of magnesium is 1.1g / L) according to the phase The ratio (organic phase: water phase) was 1:1 and mixed for 15 minutes. After the two phases were separated, the iron concentration in the feed liquid at the water phase outlet of the extraction tank was measured to drop to 0.07g / L, and the organic phase flowing out from the organic phase outlet of the extraction tank The phase is sent to the stripping tank, and water is added to the organic phase according t...

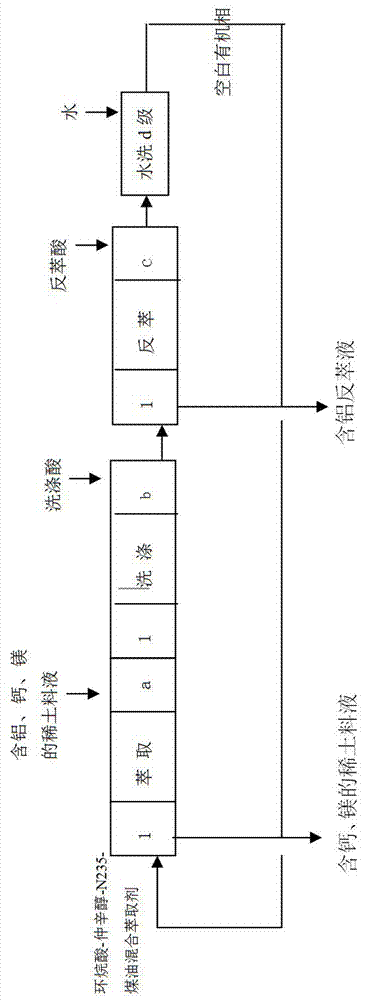

Embodiment 2

[0039] The filtrate separated from the second stirred tank of Example 1 is sent to the fourth stage of the extraction section in the fractionation extraction process one, and the first stage of the extraction section is added to be composed of naphthenic acid 10%, N235 10%, 2-octanol 40 %, the organic phase of 35% kerosene, add 0.04mol / L hydrochloric acid solution in the 3rd stage of washing section, organic phase: material liquid: the flow ratio of washing liquid is 4:1:1, in the 3rd stage of stripping section Add 1.1mol / L hydrochloric acid solution, wherein the flow ratio of the organic phase to the aqueous phase is 1:2. The organic phase flowing out from the outlet of the stripping section returns to the first stage of the extraction section for recycling after being washed with water in two stages. It has been determined that the main component of the stripping solution flowing out of the water phase outlet of the stripping section is aluminum chloride, and the content of ...

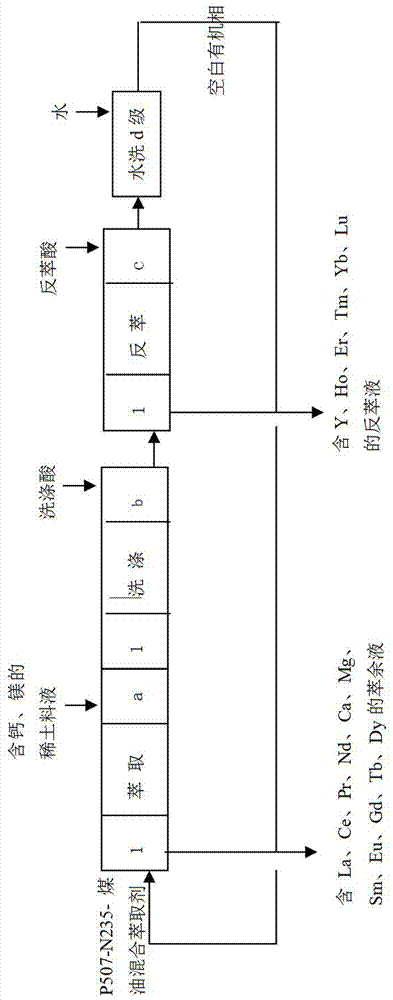

Embodiment 3

[0041] The raffinate obtained in Example 2 is sent to the fifth stage of the extraction section in the fractionation extraction separation process two, and the composition is P50750%, N235 20%, and the organic phase of kerosene 30% is added to the first stage of the extraction section, and after washing The 5th grade of section adds 1.1mol / L hydrochloric acid solution, organic phase: material liquid: the flow ratio of washing liquid is 5:1:0.5, adds 3mol / L hydrochloric acid solution in the 3rd grade of stripping section, wherein organic phase and The flow ratio of the aqueous phase was 1:3. It has been determined that the raffinate mainly composed of La, Ce, Pr, Nd, Ca, Mg, Sm, Eu, Gd, Tb, Dy is obtained at the outlet of the water phase in the extraction section, among which Y, Ho, Er, Tm, Yb, The total concentration of Lu is lower than 310ppm, and the stripping solution mainly composed of Y, Ho, Er, Tm, Yb, and Lu is obtained at the outlet of the aqueous phase of the strippin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com