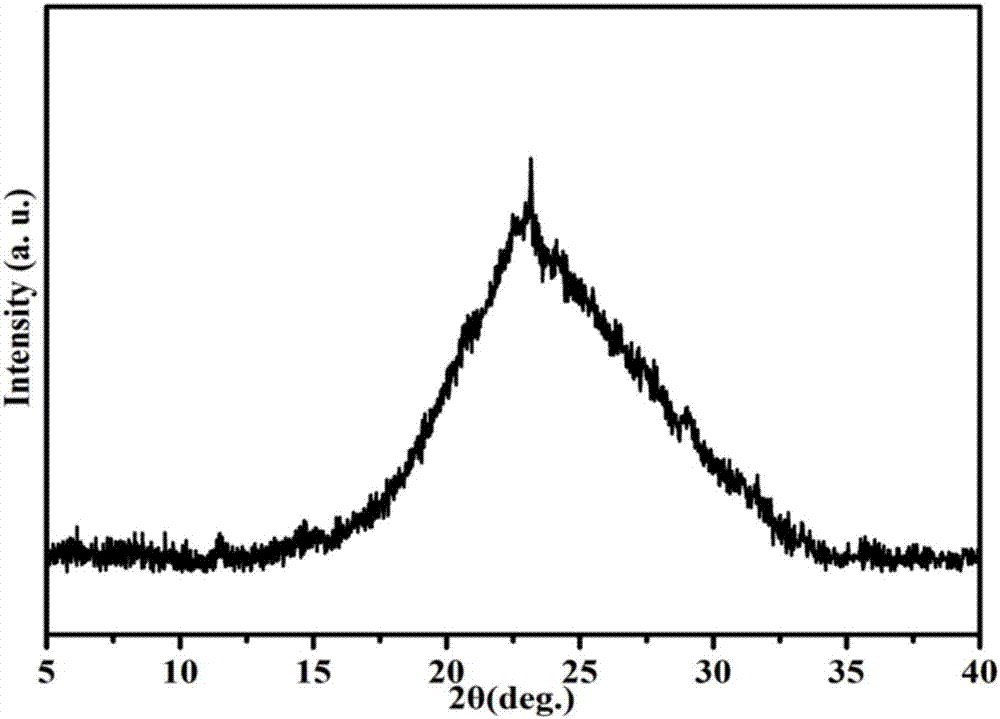

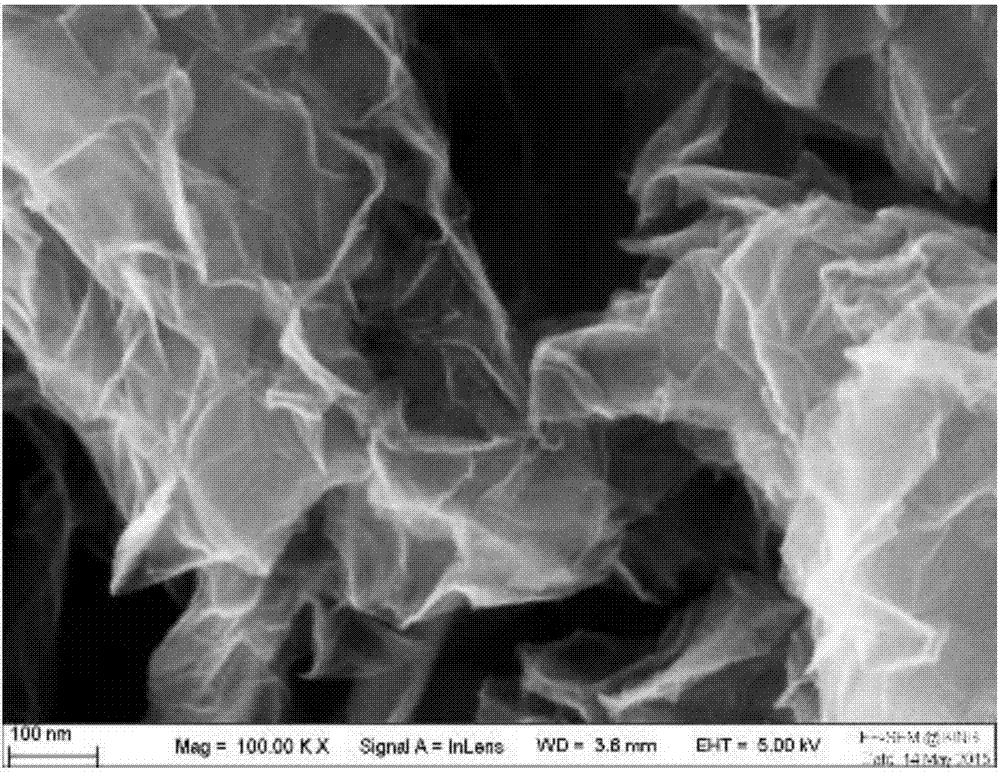

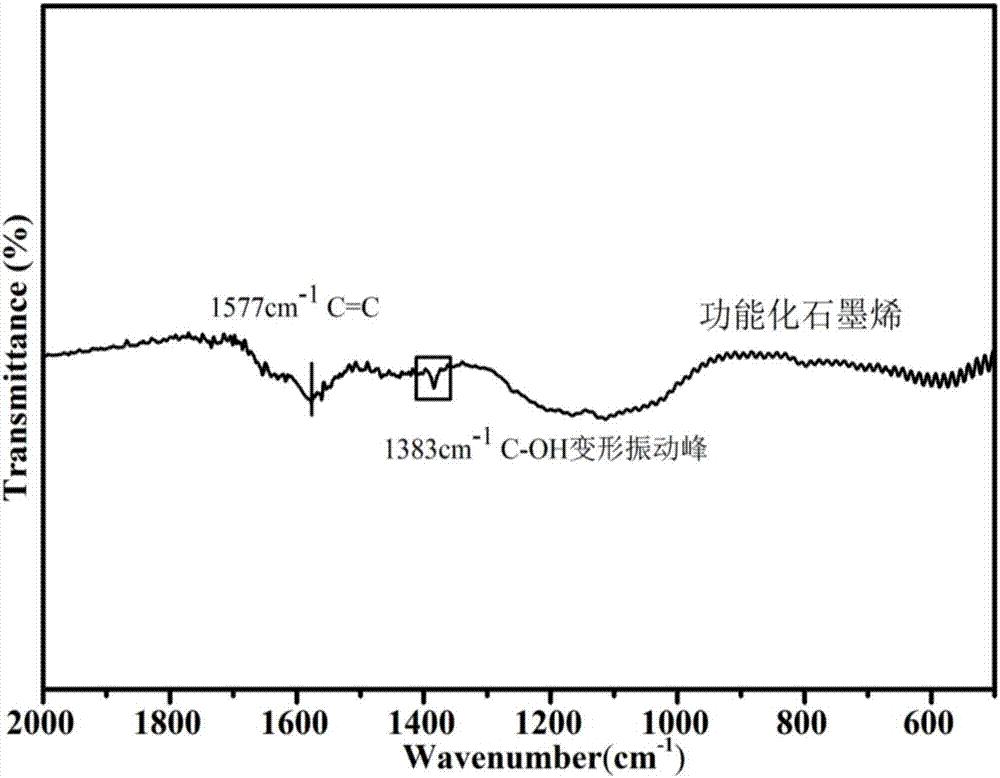

Preparation method of functionalized graphene and application of functionalized graphene in formaldehyde adsorption

A technology of graphene and graphene, which is applied in the field of preparation of functionalized graphene, can solve the problems of free pollutants, incomplete adsorption and purification of formaldehyde, etc., and achieve the effect of inhibiting free, high specific surface area and promoting decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Titanium dioxide: graphene oxide is added to deionized water according to a mass ratio of 20:1, so that the mass concentration of graphene oxide is 0.03%, and the stirring speed is 200 rpm for ultrasonic dispersion for 25 minutes to obtain graphene oxide 1. Titanium dioxide dispersion, placed in a round bottom flask;

[0021] (2) add ammoniacal liquor and hydrazine hydrate in the flask of step (1) according to the mass ratio of 10:1, fully mix, obtain mixed liquor;

[0022] (3) Place the mixed solution obtained in step (2) in an oil bath at 85°C for 2 hours to react to obtain a reaction solution;

[0023] (4) Centrifuge the reaction liquid obtained in step (3) after cooling, wash to near neutrality, and obtain functionalized graphene powder through vacuum freeze-drying.

[0024] A fixed formaldehyde detector is used to detect the concentration of formaldehyde gas absorbed by the functionalized graphene prepared by the method. After the baseline of the instrument is...

Embodiment 2

[0026] (1) Titanium dioxide: graphene oxide is added to deionized water according to the mass ratio of 20:1, so that the mass concentration of graphene oxide is 0.05%, and it is ultrasonically dispersed for 25 minutes at a stirring speed of 250 rpm to obtain graphene oxide 1. Titanium dioxide dispersion, placed in a round bottom flask;

[0027] (2) add ammoniacal liquor and hydrazine hydrate in the flask of step (1) according to the mass ratio of 15:1, fully mix, obtain mixed liquor;

[0028] (3) Place the mixed solution obtained in step (2) in an oil bath at 95°C for 1 hour to react to obtain a reaction solution;

[0029] (4) Centrifuge the reaction liquid obtained in step (3) after cooling, wash to near neutrality, and obtain functionalized graphene powder through vacuum freeze-drying.

[0030] The test method is the same as in Example 1. The functionalized graphene prepared by this method absorbs formaldehyde, and after 6 hours of adsorption, the formaldehyde removal rate ...

Embodiment 3

[0032] (1) Titanium dioxide: graphene oxide is added to deionized water according to a mass ratio of 30:1, so that the mass concentration of graphene oxide is 0.05%, and the stirring speed is 250 rpm for ultrasonic dispersion for 25 minutes to obtain graphene oxide 1. Titanium dioxide dispersion, placed in a round bottom flask;

[0033] (2) add ammoniacal liquor and hydrazine hydrate in the flask of step (1) according to the mass ratio of 15:1, fully mix, obtain mixed solution;

[0034] (3) Place the mixed solution obtained in step (2) in an oil bath at 100°C for 0.5 hours to react to obtain a reaction solution;

[0035] (4) Centrifuge the reaction liquid obtained in step (3) after cooling, wash to near neutrality, and obtain functionalized graphene powder through vacuum freeze-drying.

[0036] The test method is the same as in Example 1. The functionalized graphene prepared by this method is used to adsorb formaldehyde. After 6 hours of adsorption, the formaldehyde removal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com