Preparation method of nickel-doped zinc oxide material for detecting hydrogen

A technology of zinc oxide and sodium hydroxide, which is applied in the field of material chemistry, can solve problems such as responsiveness research, and achieve the effects of good repeatability, low raw material prices, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

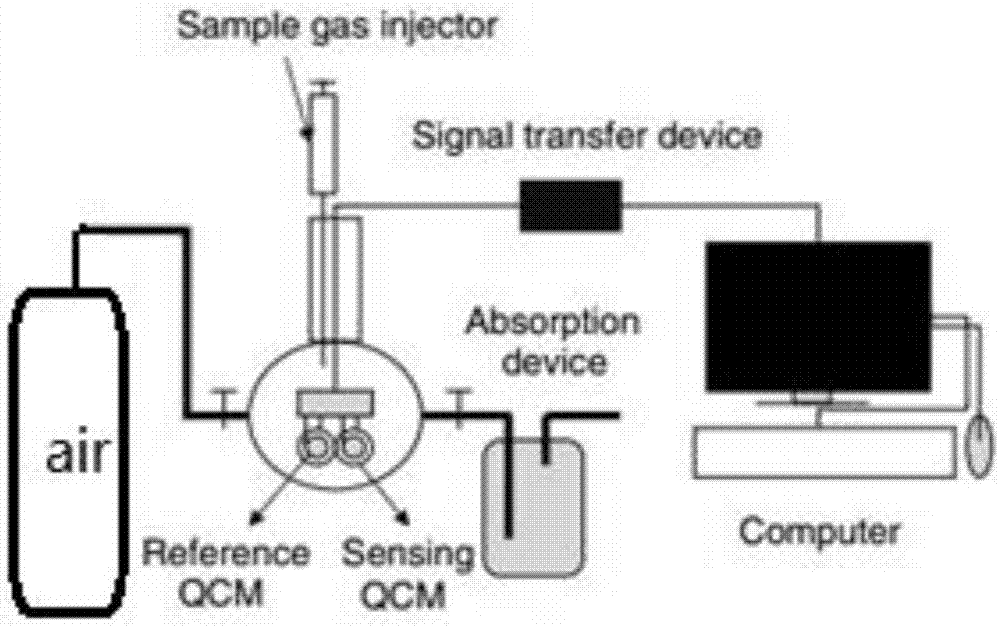

Method used

Image

Examples

Embodiment 1

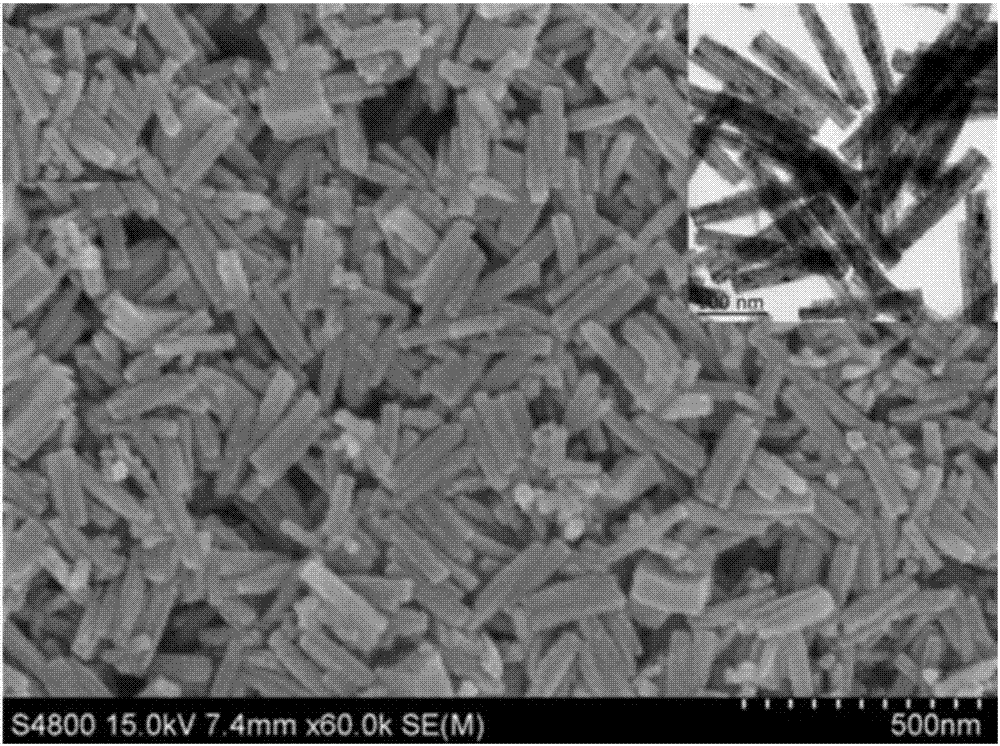

[0020] Example 1 Preparation of nano-short rod-shaped nickel-doped zinc oxide material of the present invention

[0021] Weigh zinc nitrate (3mmol), nickel nitrate (3mmol), potassium hydrogen phthalate (1.5mmol) and sodium hydroxide (6mmol) into 25-30mL water, stir and dissolve, heat to reflux temperature, and after 6 hours of reflux reaction , be cooled to room temperature, obtain solid through centrifugation, after solid is washed 2 times with distilled water, be placed in 50 ℃ of vacuum ovens and dry after 12 hours to obtain nano short rod-shaped nickel-doped zinc oxide ( figure 2 ).

Embodiment 2

[0022] Example 2 Preparation of nano-short rod-shaped nickel-doped zinc oxide material of the present invention

[0023] Weigh zinc nitrate (12mmol), nickel nitrate (12mmol), potassium hydrogen phthalate (6mmol) and sodium hydroxide (24mmol) into 200-240mL water, stir and dissolve, heat to reflux temperature, and after reflux reaction for 8 hours, After being cooled to room temperature, the solid was obtained by centrifugation. After the solid was washed 3 times with distilled water, it was placed in a vacuum oven at 70°C and dried for 16 hours to obtain nano-short rod-shaped nickel-doped zinc oxide (morphology and figure 2 basically the same).

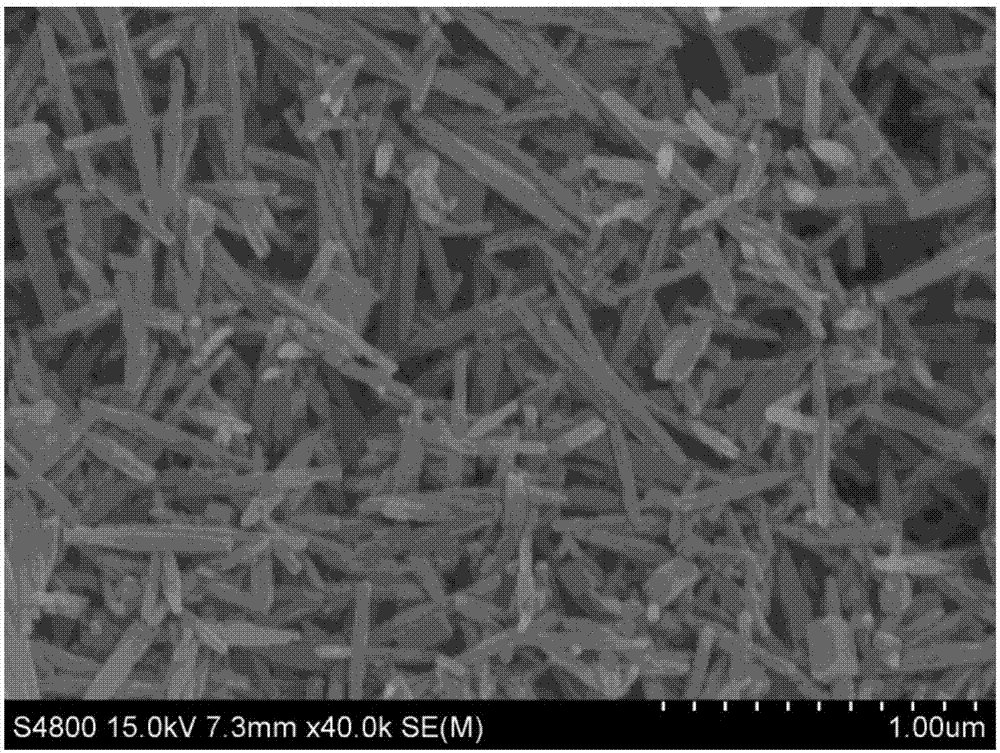

Embodiment 3

[0025] Weigh zinc nitrate (3mmol), nickel nitrate (3mmol), potassium hydrogen phthalate (3mmol) and sodium hydroxide (6mmol) into 25-30mL water, stir and dissolve, heat to reflux temperature, and after reflux reaction for 6 hours, After being cooled to room temperature, the solid was obtained by centrifugation. After the solid was washed twice with distilled water, it was placed in a vacuum oven at 50°C and dried for 12 hours to obtain nanofibrous nickel-doped zinc oxide ( image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com