Method for purifying chlorine-containing wastewater discharged during zinc hydrometallurgy

A technology for zinc hydrometallurgy and wastewater purification, which is applied in chemical instruments and methods, electrolysis process, metallurgical wastewater treatment, etc., can solve the problems such as the difficult treatment of chlorine-containing wastewater, and achieve the effect of high utilization rate and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

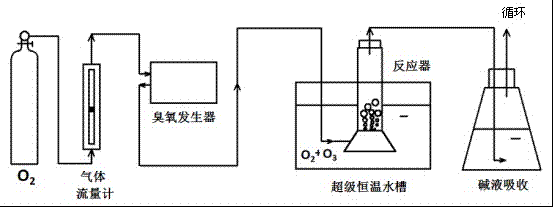

[0020] (1) After the oxygen is decompressed, the flow rate is controlled by the flow meter and then introduced into the ozone generator. The internal discharge tube of the ozone generator converts part of the oxygen into ozone under the action of a high-voltage, high-frequency electric field, and the generated ozone and unionized gas Form a mixed gas, wherein the ozone concentration in the mixed gas is 55 mg / L.

[0021] (2) Disperse the mixed gas obtained in step (1) evenly through a gas distributor and mix it with a chlorine ion concentration of 1000 mg / L, a sulfuric acid concentration of 50 g / L, a zinc ion concentration of 4 g / L, and a manganese ion concentration. Concentration of 0.1 g / L of wastewater at 70 ° C conducts contact reaction for 60 min, completes dechlorination and discharges waste gas containing a small amount of chlorine.

[0022] (3) The chlorine ion concentration of the wastewater treated in step (2) is 80 mg / L, and the dechlorination rate is 92%.

[0023]...

Embodiment 2

[0026] (1) After the oxygen is decompressed, the flow rate is controlled by the flow meter and then introduced into the ozone generator. The internal discharge tube of the ozone generator converts part of the oxygen into ozone under the action of a high-voltage, high-frequency electric field, and the generated ozone and unionized gas Form a mixed gas, wherein the ozone concentration in the mixed gas is 75 mg / L.

[0027] (2) Disperse the mixed gas obtained in step (1) evenly through the gas distributor, and then mix it with the chlorine ion concentration of 1500 mg / L, sulfuric acid concentration of 25 g / L, zinc ion concentration of 10 g / L, manganese ion concentration The concentration of wastewater is 5 g / L at 30 ° C carries out contact reaction for 180 min, completes dechlorination and discharges waste gas containing a small amount of chlorine.

[0028] (3) The chlorine ion concentration of the wastewater treated in step (2) is 250 mg / L, and the dechlorination rate is 83.33%....

Embodiment 3 1)

[0031] Embodiment 3 (1) After the oxygen is decompressed, the flow rate is controlled by the flow meter and then introduced into the ozone generator. The internal discharge tube of the ozone generator converts part of the oxygen into ozone under the action of a high-voltage, high-frequency electric field. The ionized gas forms a mixed gas, and the ozone concentration in the mixed gas is 150 mg / L.

[0032] (2) Disperse the mixed gas obtained in step (1) evenly through the gas distributor, and then mix it with the chlorine ion concentration of 2000 mg / L, sulfuric acid concentration of 100 g / L, zinc ion concentration of 25 g / L, manganese ion concentration The concentration of wastewater is 3 g / L at 50 ° C carries out contact reaction for 120 min, completes dechlorination and discharges waste gas containing a small amount of chlorine.

[0033] (3) The chlorine ion concentration of the wastewater treated in step (2) is 150 mg / L, and the dechlorination rate is 92.5%.

[0034] (4) Pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com