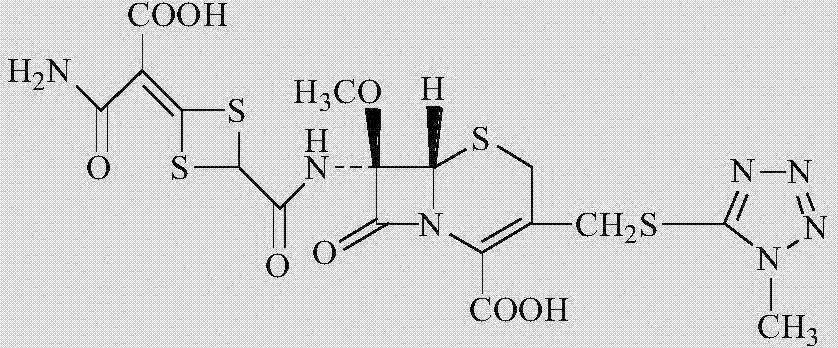

Preparation method of high-purity cefotetan disodium for injection

A technology for cefotetan disodium and injection, which is applied in purification process, preparation of cefotetan disodium, and production of high-purity pharmaceutical compounds for injection, can solve problems such as easy breakage, affect product quality, etc., achieve reaction Thorough, avoid quality risk, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The method for preparing high-purity cefotetan disodium for injection of the present invention has the following specific implementation steps:

[0035] a. Under the protection of nitrogen, the reaction material 7-MAC (chemical name 7β-amino-7α-methoxy-3-(1-methyl-1H-tetrazole-5-thiomethyl)-3-cephalosporin Diphenylmethyl ene-4-carboxylate) was dissolved in the solvent dichloromethane, the temperature was reduced to -25~-40℃, pyridine was added as a catalyst, and the dichloromethane solution of the acylating agent was added, stirred uniformly and acylated For the reaction, the reaction temperature is controlled at -20 to -40°C, and the reaction time is 15 to 45 minutes; the acylating agent is any one or a mixture of chloroacetyl chloride or bromoacetyl bromide.

[0036] b. Adjust the pH of the solution after the reaction in step a to below 1.0 with dilute sulfuric acid or dilute hydrochloric acid. After the solution is allowed to stand for phase separation, the dichloromethan...

Embodiment 1

[0042] a. Under the protection of nitrogen, dissolve the reaction raw material 7-MAC in the solvent dichloromethane, reduce the temperature to -38°C, add pyridine as a catalyst, and then add the dichloromethane solution of the acylating agent chloroacetyl chloride, stir well and proceed. For acylation reaction, the reaction temperature is controlled at -35°C, and the reaction time is 30 minutes;

[0043] b. Adjust the pH of the solution after the reaction in step a to 0.5 with dilute sulfuric acid or dilute hydrochloric acid. After the solution is allowed to stand for phase separation, the dichloromethane phase is separated, and purified water is added to the dichloromethane phase, and the solution is allowed to stand again Phase and separate the dichloromethane phase, add anhydrous magnesium sulfate to the dichloromethane phase separated again, stir well, filter, remove the filter residue, add equal mass mixed n-butanol, dichloromethane, Ethyl acetate and tetrahydrofuran are use...

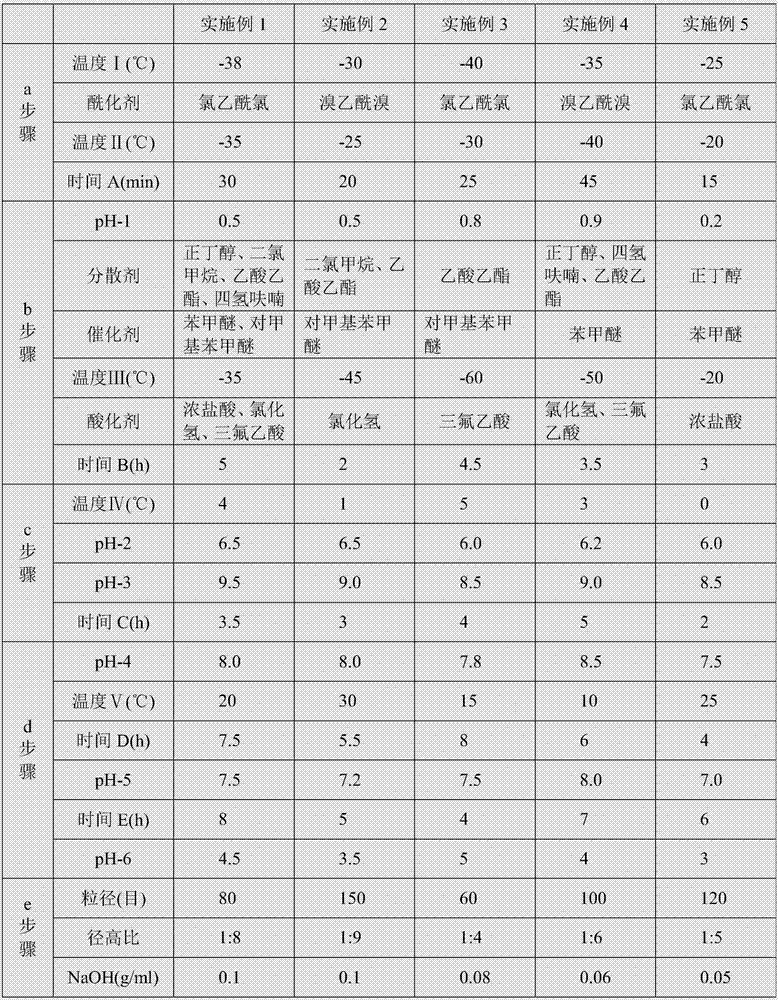

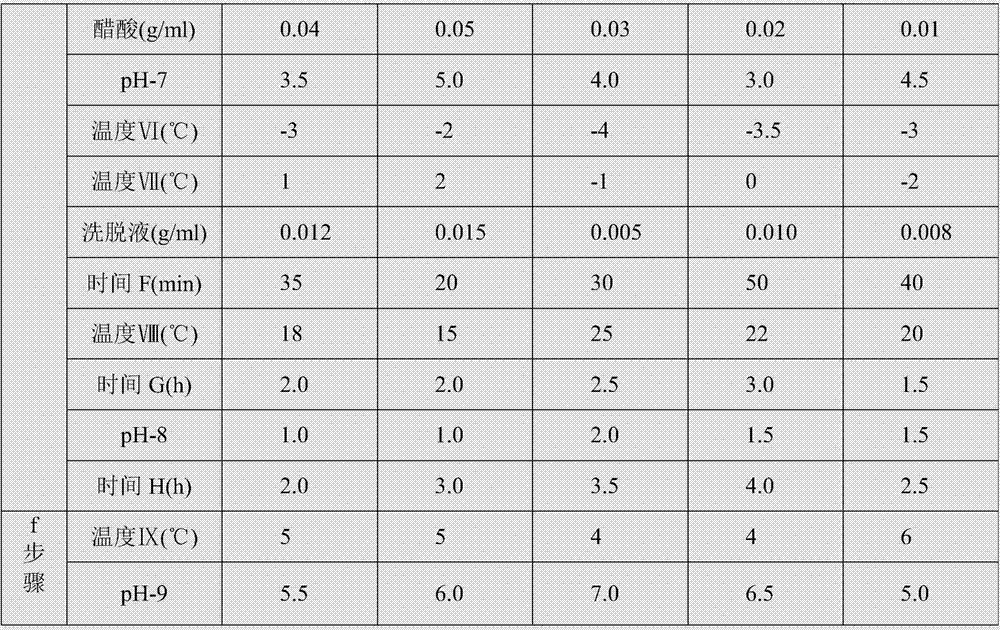

Embodiment 2~5

[0049] The steps of the preparation method used in Examples 2 to 5 are the same as those in the foregoing Example 1, and the different process parameters or the selected different types of compounds are shown in Table 1 below. Among them, "temperature I" in step a represents the temperature reached by 7-MAC after being dissolved in dichloromethane; "temperature II" represents the temperature during the acylation reaction; "time A" represents the time of the acylation reaction; step b Among them, "pH-1" represents the pH value of the solution after the reaction in step a is adjusted with dilute sulfuric acid or dilute hydrochloric acid; "Temperature III" represents the temperature reached after adding the catalyst; "Time B" represents the time of the hydrolysis reaction; In step c, "temperature IV" represents the temperature after ice water is added; "pH-2" represents the pH value of the solution before the phase separation; "pH-3" represents the pH value of the condensation reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com