Graphite composite ABS multifunctional resin and preparation method thereof

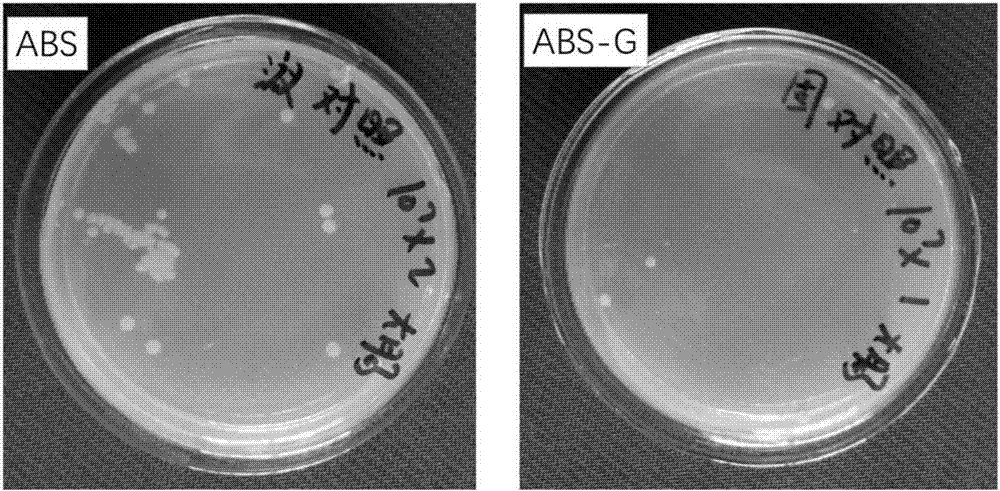

A graphene composite and ABS resin technology, applied in the field of nano-filler preparation and composite material modification, can solve the problems of low preparation cost, uneven dispersion of graphene, short post-processing cycle, etc., and achieve good antistatic and antibacterial properties , expand the application field and use environmental conditions, and solve the effect of serious loss of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

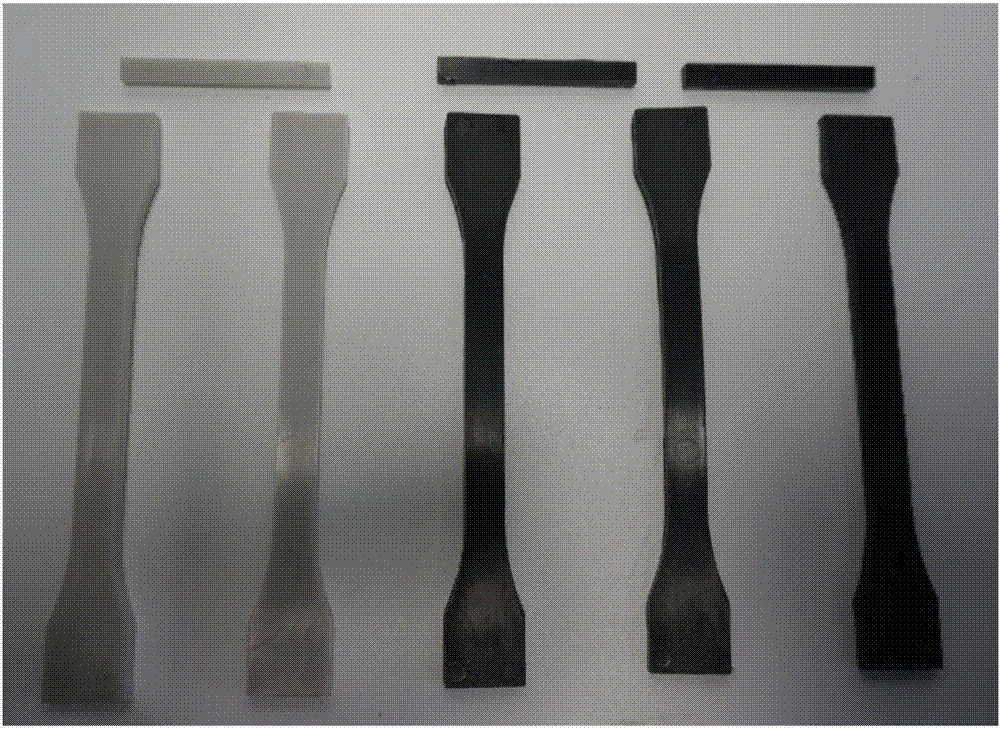

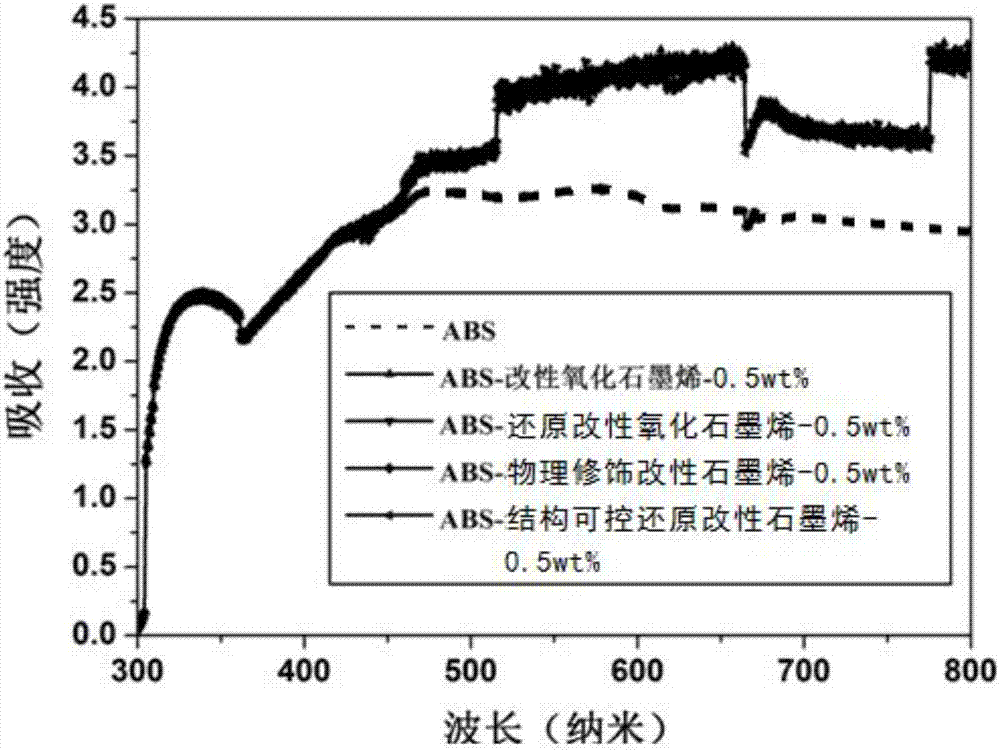

Embodiment 1

[0049] Present embodiment relates to a kind of graphene composite ABS multifunctional resin, and it comprises each component of following parts by weight:

[0050] ABS resin 100 parts,

[0051] 5 parts of modified graphene,

[0052] Compatibilizer 1 part.

[0053] Wherein, the modified graphene is physically modified modified graphene, and the compatibilizer is a titanate coupling agent.

[0054] The preparation method of above-mentioned graphene composite ABS multifunctional resin is:

[0055] (1) The preparation method of the above-mentioned modified graphene is: the graphene prepared by physical method is ultrasonically dispersed in ethanol or methylpyrrolidone solvent, and the polymer modifier PVDF (vinylidene fluoride) is added to process, and the amount of PVDF is 1.5 times the mass of graphene, centrifuge to obtain modified modified graphene, and finally replace the solvent with an aqueous solution, cool and dry.

[0056] (2) After the modified graphene powder prepa...

Embodiment 2

[0061] Present embodiment relates to a kind of graphene composite ABS multifunctional resin, and it comprises each component of following parts by weight:

[0062] ABS resin 100 parts,

[0063] 3 parts of modified graphene,

[0064] Compatibilizer 0 parts

[0065] Wherein, the modified graphene is modified graphene oxide.

[0066] The preparation method of above-mentioned graphene composite ABS multifunctional resin is:

[0067] (1) The preparation method of the above-mentioned modified graphene is: firstly prepare and simply clean the graphite oxide obtained by the Hummers method, then directly sonicate the graphene oxide dispersion for 30 min under the acidic condition of pH>2, and then directly obtain the graphene oxide dispersion under stirring conditions Next, add the modifier PDDA, and 10g of graphene oxide corresponds to 10-20g of PDDA. Finally, the modified graphene oxide obtained by suction filtration can be frozen and dried.

[0068] (2) The modified graphene pow...

Embodiment 3

[0073] Present embodiment relates to a kind of graphene composite ABS multifunctional resin, and it comprises each component of following parts by weight:

[0074] ABS resin 100 parts,

[0075] 1 part of modified graphene,

[0076] Compatibilizer 1 part

[0077] Wherein, the modified graphene is structurally controllable reduction-modified graphene, and the compatibilizer is an aluminate coupling agent.

[0078] The preparation method of above-mentioned graphene composite ABS multifunctional resin is:

[0079] (1) The preparation method of the above-mentioned modified graphene is: choose 5g of graphite oxide and disperse it in a 5L large beaker, and simply ultrasonically disperse it for 10min, then heat it to 35 degrees and add 2g of octadecyl dimethyl with solid content under mechanical stirring A solution of amine oxide is used to obtain modified graphene oxide. After reverse precipitation, it is suction-filtered and dried. After heat-dried, it is crushed, and it is quick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com