Method of producing tetrahydropyrimidine by fermenting recombinant corynebacterium glutamicum

A technology of Corynebacterium glutamicum and tetrahydropyrimidine, which is applied in the fields of genetic engineering and biological fermentation, can solve the problems of complicated separation process, increase production cost and the like, and achieve the effects of simplifying extraction process, simplifying fermentation process and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

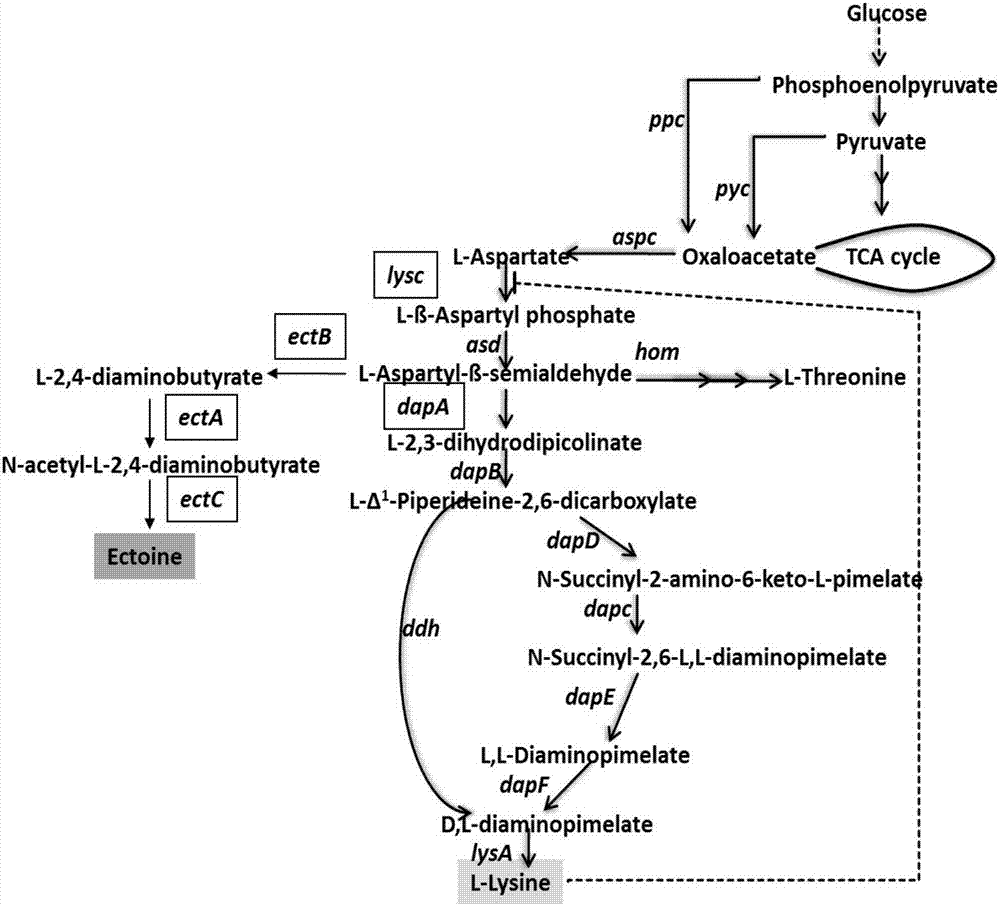

[0029] Example 1 Overexpression of aspartokinase gene lysC that relieves feedback inhibition

[0030] The immediate precursor for the synthesis of ectoine is aspartate, and aspartokinase, the first enzyme in the synthesis pathway from aspartate to ectoine, is feedback-inhibited by lysine and threonine. Therefore, the present invention removes the feedback inhibition of the enzyme by lysine and threonine at first by introducing site-directed mutation Q298G in the aspartokinase gene, and inserts a strong promoter P1( The sequence is 5'-ggtgcacaaagCAAAAGCTGGGTACCCTATCTGGTGCCCTAAACGGGGGAATATTAACGGGCCCAGGGTGGTCGCACCTTGGTTGGTAGGAGTAGCATGGGATCC-) (SEQ ID NO. 4) to enhance the expression of the gene. The specific implementation process is as follows:

[0031]Using the genome of Corynebacterium glutamicum MB001 (Baumgart M et al, Appl Environ Microbiol 79:6006-15 (2013)) as a template, primers lysC-1-F (aggaaacagctatgacatgattacgtttcgcccagaaccaagtagcc) and lysC-1-R (CCCAGCTTTTGctttgtgc...

Embodiment 2

[0032] Example 2 Promoter replacement weakens the expression of dihydropyrimidinedicarboxylate synthase gene dapA

[0033] Since the main fermentation product of the recombinant strain C. glutamicum lysC-P1-298 is lysine, in order to make more substrates for the synthesis of ectoine, the expression of the dihydropyrimidinedicarboxylate synthase gene dapA was further weakened.

[0034] Using the genome of Corynebacterium glutamicum MB001 as a template, PCR was performed with primers dap-1-F (ctatgacatgattacgaattcagatggttttcctgaccagctt) and dap-1-R (gggaagaaggaaaccttgaactctatgagcacagg) to obtain a gene fragment dap1 of about 1.0 kb and purify the PCR product. Using the genome of Corynebacterium glutamicum MB001 as a template, PCR was performed with primers dap-2-F (ttcaaggtttccttcttccctcatttggggg) and dap-2-R (tgcctgcaggtcgactctagaggcctgtaaaggctcatttcag) to obtain a gene fragment dap2 of about 1.0 kb and purify the PCR product. The Corynebacterium glutamicum suicide plasmid pK18...

Embodiment 3

[0035] Example 3 Overexpression of ectABC, a gene related to the synthesis pathway of ectoine

[0036] In order to strengthen the expression of key genes in the ectoine synthesis pathway, the ectABC gene was artificially synthesized, the sequence of which is shown in SEQID NO.3. Halomonas elongata DSM2581 genome was subjected to PCR using primers ectABC-F (tgcatgcctgcaggtcgactAGGAGGCCCTTCAGatgaacg) and ectABC-R (ccgccaaaacagccaagctgttacagcggcttctggtcgt) as primers to obtain a gene fragment ectABC of about 2.5kb and purify the PCR product. The Corynebacterium glutamicum expression plasmid pXMJ19 (purchased from addgene) was double digested with EcoRI / XbaI, and the ectABC gene fragment was ligated to pXMJ19 in one step using the Gibson Assembly kit (NEB). The obtained recombinant plasmid was named pXMJ-ectABC. Using an electroporator (Bio-Rad), transfer pXMJ-ectABC into Corynebacterium glutamicum lysC-dap by electroporation, the electric shock conditions are voltage 2.5KV, resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com