Method for preparing heavy metal adsorbing material by modifying silk fiber and application of material

An adsorption material and silk fiber technology, applied in the direction of alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problem that the adsorption capacity of heavy metal ions is not high, it cannot be directly used as a heavy metal adsorbent, and the content of free amino groups and carboxyl groups There are no major problems, and the effect of being convenient for large-scale application, low cost, and promoting the amount is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

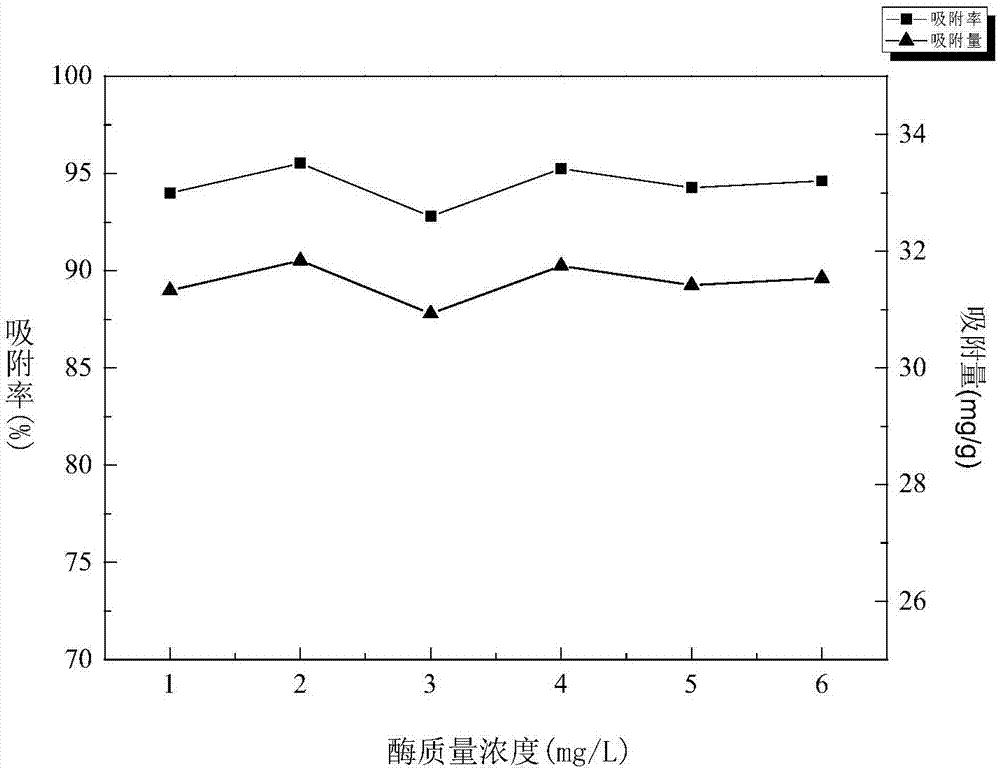

[0057] Embodiment 1: the influence effect of dispase mass concentration on silk fibroin

[0058]When the mass concentration of neutral protease is 1, 2, 3, 4, 5, 6g / L, the bath ratio is 1:100, the temperature is 60°C, the power is 60%, and the treatment time is 60min, the modified silk (silk fibroin) can be obtained The modified silk 0.3g obtained according to different enzyme mass concentrations is added in 100mg / L (100mL) Cu (Ⅱ) solution respectively, and the adsorption amount adsorption rate change curve of the adsorption of heavy metal Cu (Ⅱ) is as follows: figure 2 shown.

[0059] From image 3 It can be seen that the concentration of enzyme has a significant effect on the adsorption of Cu(II) on silk modified by neutral protease, and it is also one of the factors affecting the adsorption rate. When the concentration of enzyme in the solution increased from 1mg / L to 2mg / L, the adsorption capacity and adsorption rate of heavy metal Cu(II) gradually increased. When the c...

Embodiment 2

[0060] Embodiment 2: the influence effect of neutral protease treatment time on silk fibroin

[0061] When the treatment time is 20, 40, 60, 80, 100, 120min, the enzyme mass concentration is 3g / L, the bath ratio is 1:100, the temperature is 60°C, and the power is 60%, the modified silk (i.e. silk fibroin) is obtained; Weighing 0.3 g of the obtained modified silk according to different treatment times and adding it to 100 mg / L (100 mL) Cu(II) solution, the adsorption capacity and adsorption rate curve of heavy metal Cu(II) are as follows: Figure 4 shown.

[0062] From Figure 4 It can be seen that the enzyme treatment time is also one of the main factors affecting silk fibroin. Under different treatment times, the adsorption amount and adsorption rate have little change and the adsorption effect is good, the adsorption amount is above 31.11 mg / g, and the adsorption rate is above 93%. Therefore, the neutral protease treatment time had little effect on silk fibroin and the ad...

Embodiment 3

[0063] Embodiment 3: the influence effect of dispase treatment temperature on silk fibroin

[0064] When the treatment temperature is 30, 40, 50, 60, 70, 80°C, the mass concentration of neutral protease is 3g / L, the bath ratio is 1:100, and the power is 60%, the modified silk (i.e. modified silk fibroin) can be obtained The modified silk 0.3g obtained according to different treatment temperatures is added in 100mg / L (100mL) Cu (Ⅱ) solution respectively, and the adsorption rate variation curve of the adsorption of heavy metal Cu (Ⅱ) is as follows: Figure 5 shown.

[0065] From Figure 5 It can be seen that the neutral protease treatment temperature also has an effect on silk fibroin. When the temperature increased from 30°C to 50°C, the adsorption capacity and rate increased. At 50°C, the adsorption capacity and rate reached the maximum, which were 34.63 mg / g and 94.89%, respectively. When the temperature increased from 50 °C to 80 °C, the adsorption capacity Both the adsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com