Preparation method for nanofiber porous membrane for carrying high-activity nanometal particles

A technology of nano-metal particles and nano-fibers, which is applied in the field of preparation of nano-fiber porous membranes, can solve problems such as difficulty in realizing high-capacity loading of nano-metal particles, difficulty in improving the density of active sites on the surface of fibers and surface activity, and achieve improved performance , improve the effect of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

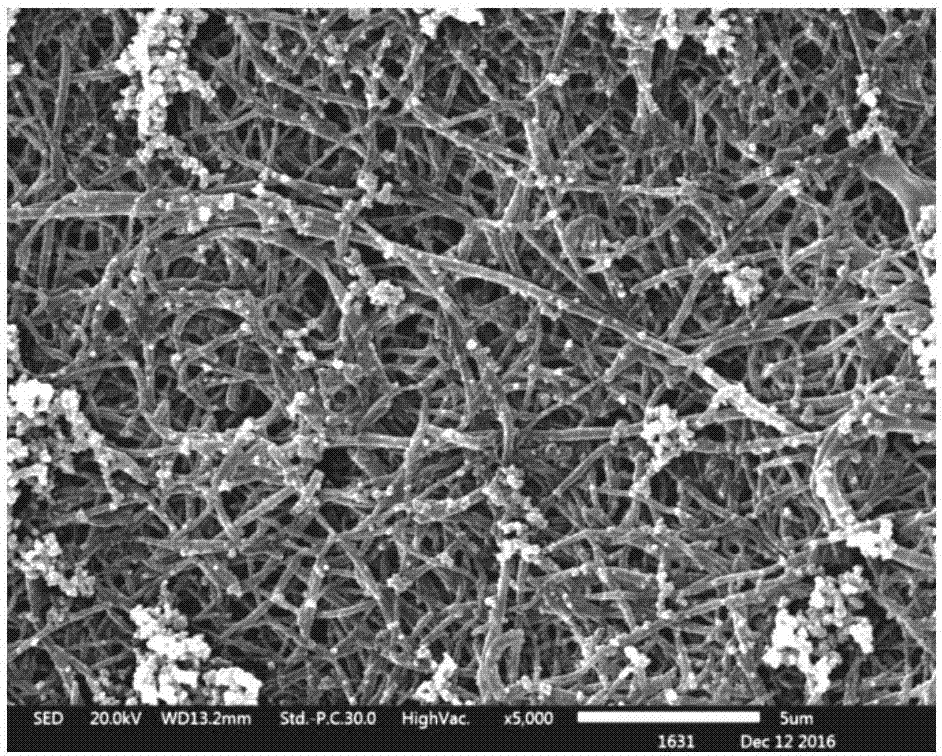

[0035] This embodiment discloses a preparation method of an ethylene vinyl alcohol copolymer nanofibrous porous membrane loaded with highly active nano-silver particles. The preparation method includes the following steps:

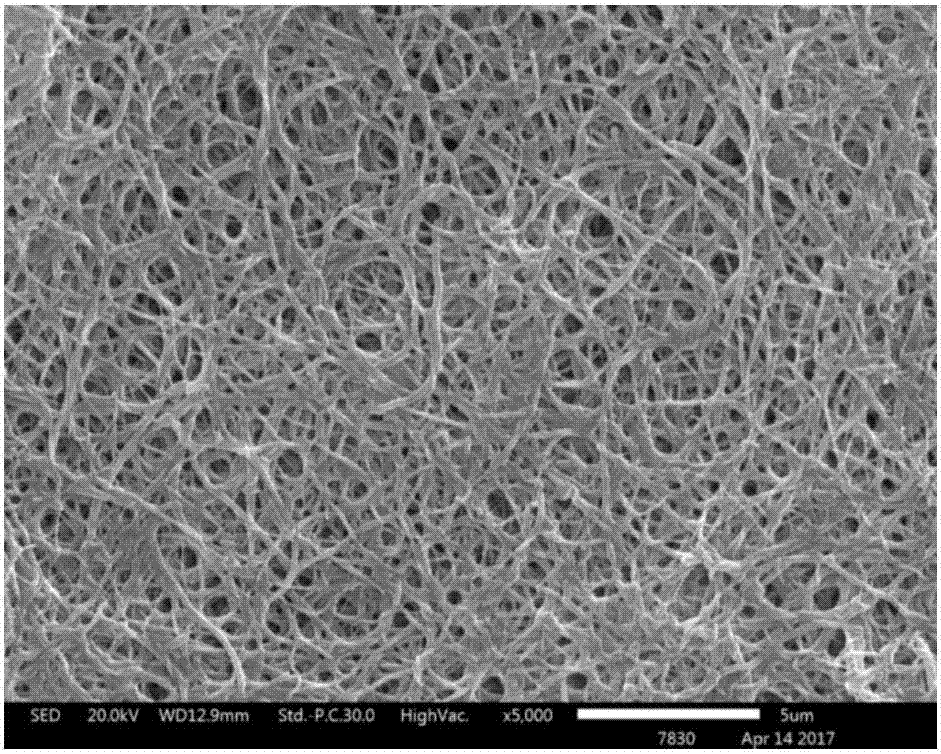

[0036] (1) The nanofiber suspension is coated on one surface of the nonwoven substrate by spraying, the coating thickness is 10 μm, and the coating density is 5 g / m 2 , vacuum-dried at room temperature, prepared figure 1The shown nanofiber porous base membrane consists of a nonwoven substrate and a nanofiber coating attached to its surface, in which the nanofiber suspension consists of ethylene vinyl alcohol copolymer nanofibers dispersed in the mass ratio of ethanol to deionized water It is prepared by stirring in a 1:1 mixed solvent, and the solid content of the nanofiber is 0.5wt%.

[0037] (2) Soak the nanofiber porous base membrane in ethanol to remove surface impurities, then put it into the prepared dopamine hydrochloride aqueous solution, and reac...

Embodiment 2

[0050] This example discloses a preparation method of an ethylene vinyl alcohol copolymer nanofibrous porous membrane loaded with highly active gold nanoparticles. The preparation method includes the following steps:

[0051] (1) The nanofiber suspension is coated on one surface of the nonwoven substrate by spraying, the coating thickness is 20 μm, and the coating density is 8 g / m 2 , vacuum-dried at room temperature, prepared figure 1 The shown nanofiber porous base membrane consists of a nonwoven substrate and a nanofiber coating attached to its surface, in which the nanofiber suspension consists of ethylene vinyl alcohol copolymer nanofibers dispersed in the mass ratio of ethanol to deionized water It is prepared by stirring in a 1:1 mixed solvent, and the solid content of the nanofiber is 2wt%.

[0052] (2) Soak the nanofiber porous base membrane in ethanol to remove surface impurities, then put it into the prepared dopamine hydrochloride aqueous solution, and react in a ...

Embodiment 3

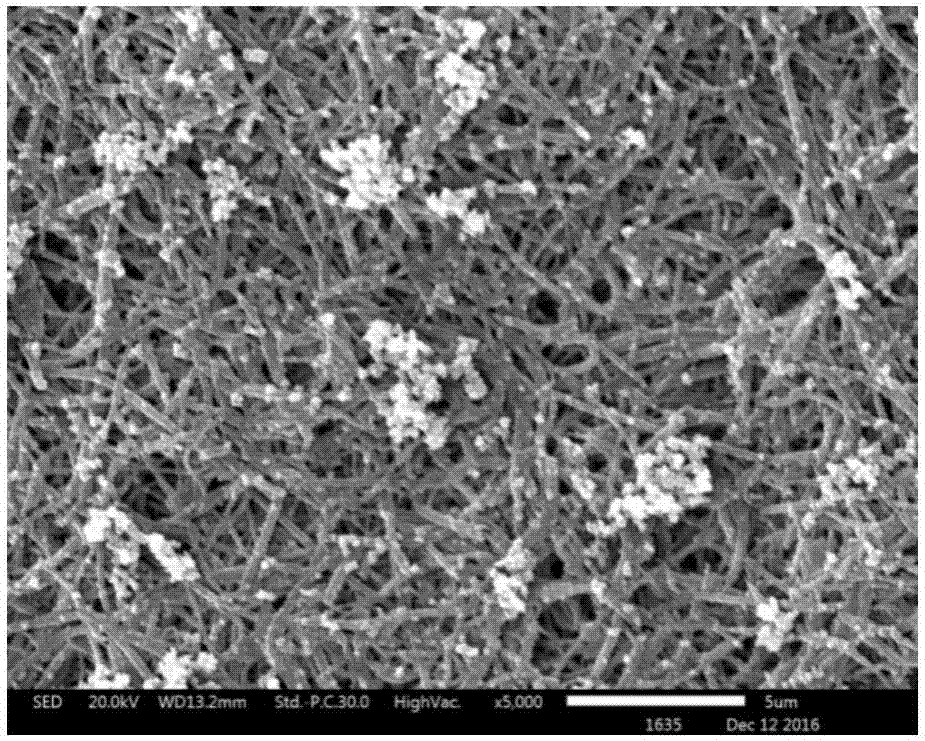

[0065] This embodiment discloses a preparation method of an ethylene vinyl alcohol copolymer nanofibrous porous membrane loaded with highly active nano-platinum particles. The preparation method includes the following steps:

[0066] (1) The nanofiber suspension is coated on one surface of the nonwoven fabric substrate by spraying, the coating thickness is 50 μm, and the coating density is 12 g / m 2 , vacuum-dried at room temperature, prepared figure 1 The shown nanofiber porous base membrane consists of a nonwoven substrate and a nanofiber coating attached to its surface, in which the nanofiber suspension consists of ethylene vinyl alcohol copolymer nanofibers dispersed in the mass ratio of ethanol to deionized water It is formed by stirring in a 1:1 mixed solvent, and the solid content of the nanofiber is 5wt%.

[0067] (2) Soak the nanofiber porous base membrane in ethanol to remove surface impurities, then put it into the prepared dopamine hydrochloride aqueous solution, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com