Method for preparing fuel oil by hydrothermally liquefying kitchen waste

A technology for kitchen waste and hydrothermal liquefaction, which is applied in chemical instruments and methods, preparation of biofuels, and liquid hydrocarbon mixtures, etc. The effect of reducing pollution and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

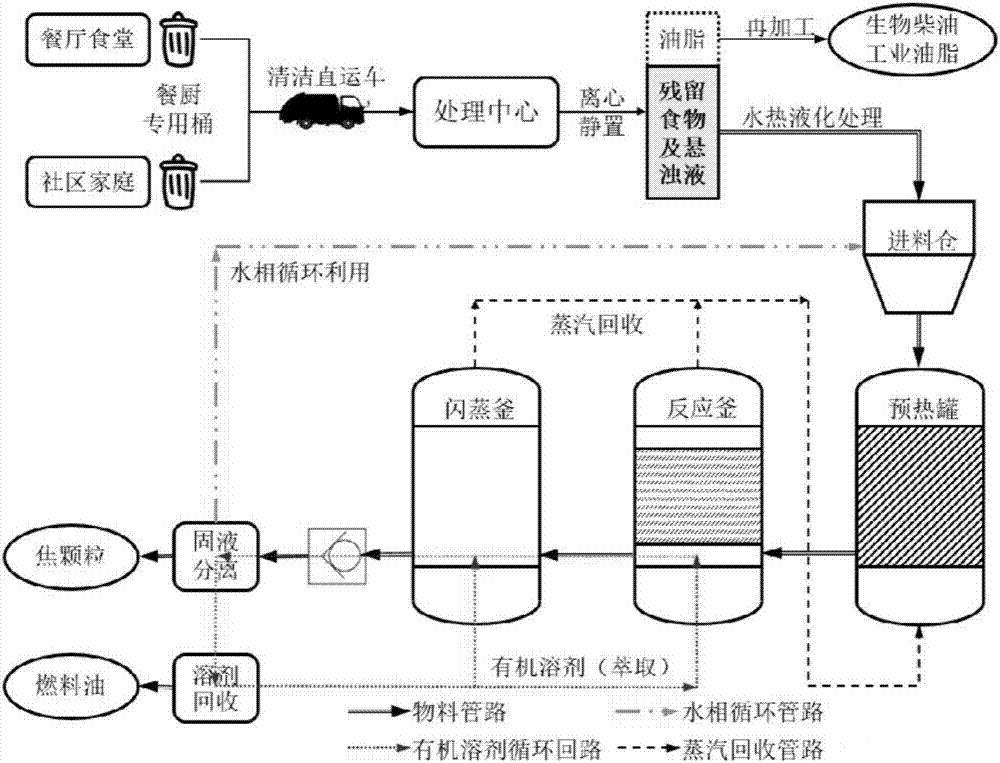

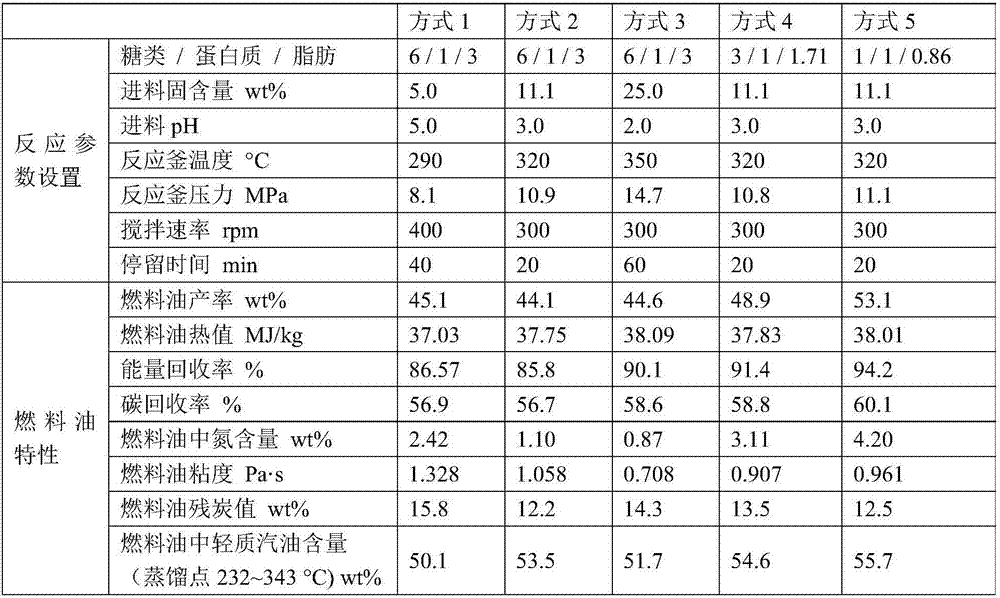

[0050] Such as figure 1As shown, after collecting and transporting the garbage in the special bucket for food waste to the processing center, sort out impurities such as plastics, fabrics, and large bones in the food waste. Centrifuge the sorted food waste and collect the upper layer of oil separately as industrial raw materials; coarsely crush the residual food and suspension in the lower layer. After crushing, there are no obvious large pieces of food, and the particle size is less than 10cm. The coarsely crushed swill suspension was mixed with circulating water, so that the solid content of the mixed liquid was 11.1 wt%, and the pH was adjusted to 3.0. The mixed food waste is sent to the preheating tank through the feed bin, and the high-temperature steam recovered after flash evaporation is used to preheat the feed, and the final temperature of preheating is 90°C. Put the preheated kitchen waste into the reactor, heat it to 320°C, the pressure is 10.9MPa, the stirring spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com